The ultimate goal for Plastic Scanner is to become a fully portable unit. That looks increasingly doable. Before getting the production unit ready, there are a few things to smoothen out. I saw a few in their Discord server (and that sound all too familiar!):

- Testing testing testing

- "Great! this is the perfect component! What do you mean "0 in stock, Ship date estimate 2025"??"

During the testing phase there will be a lot of plastic samples, and the devboards are going to be moving around a lot. PCB's are pretty sturdy, but a lot of touching cannot be good for them.

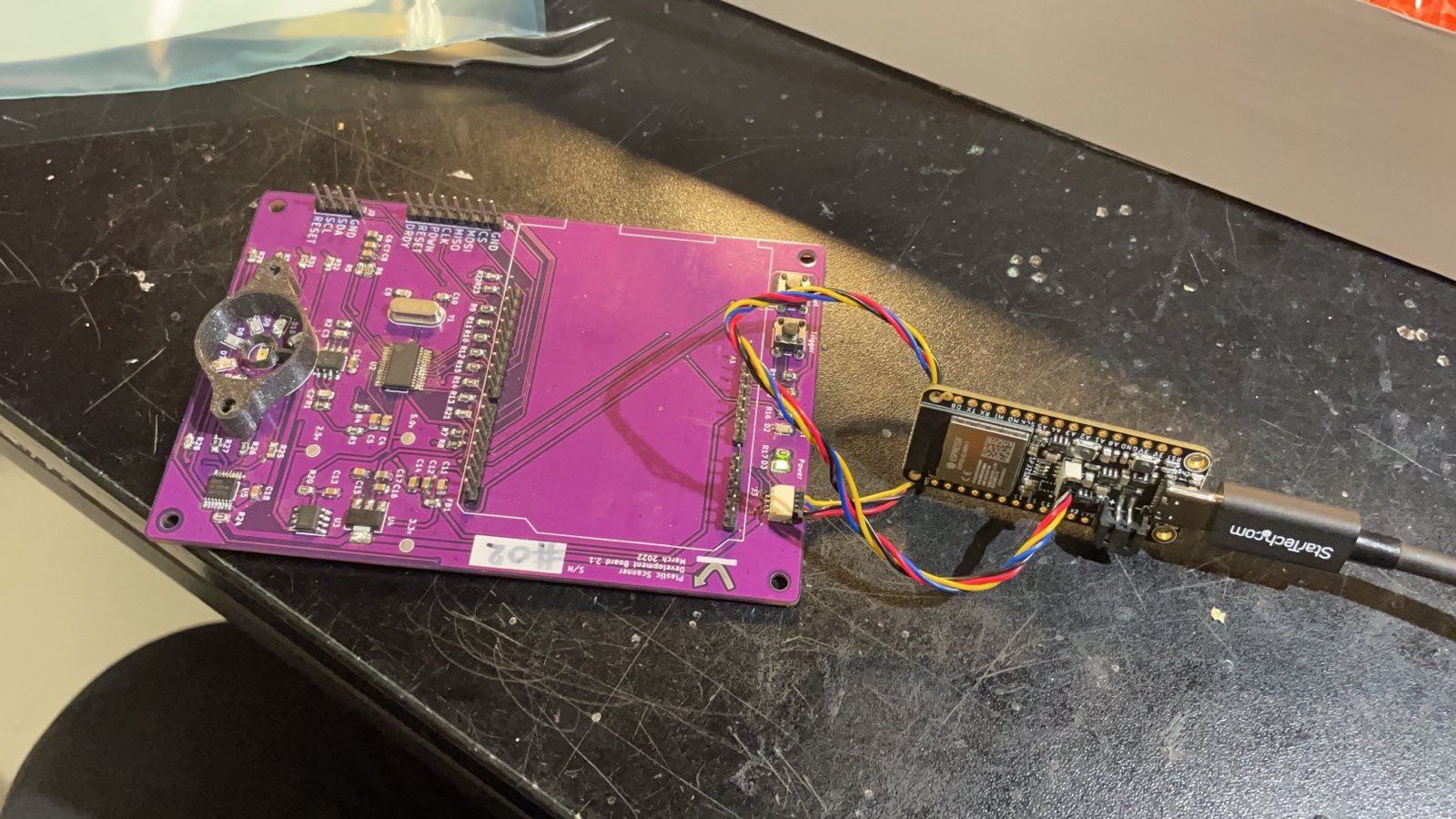

I took a long look at their devboard in order to see what I would be working with.

The first devboard was an Arduino UNO, but they are still exploring different options, one of the chief factors mentioned above is the supply chain resilience. There are a few factors that remain the same, however: LED's array on top of it, shape, assembly holes.

Giovanni

Giovanni

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.