More log catch-up...

The project subtitle includes "very DIYable". I can say so, but proving so remains for others to do.

While I've been not updating logs here, a couple of builders on Discord have completed their own "Minamil"-like machines up to first cuts. They've hit some major milestones for the project and I'm well late at saying so.

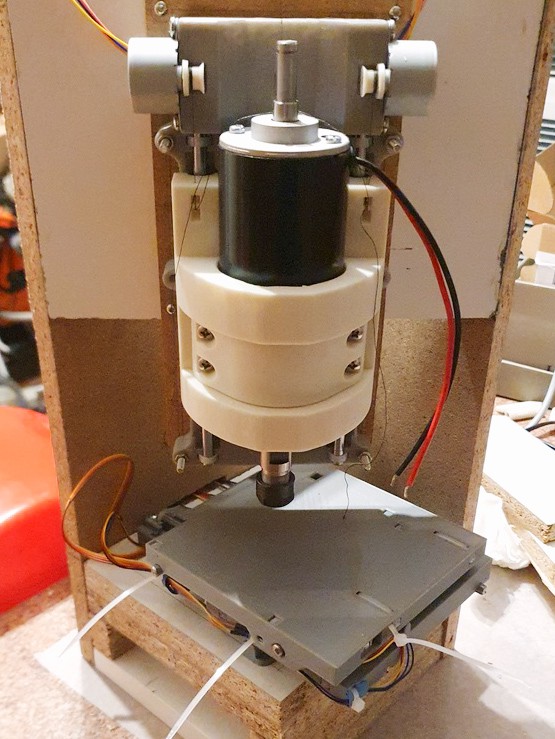

Discorder janvorli has built his machine with a proper spindle:

He started with a Dremel 300 in mind (I.e. in hand) which almost but not quite fit in the Z tool clamp. Then he found a too-good-to-pass deal on the 52mm spindle bundled with power supply etc. So there are a couple more versions of the Z sled to be found in Discord chat history, or for asking:

- slightly modified for compatibility with Dremel 300 in addition to whatever else already fit

- more modified for 52mm spindle only (& clearance for 54mm fan if present)

In the photo above, janvorli has two Z motors rigged. That didn't work. ...I think the 'why' will get its own log entry... What does work for this ~1kg spindle is a single motor and 2:1 purchase. He bored the tie-off bit out the printed part and fitted part of a 3mm smooth metal rod from an old floppy drive. The hoist cord coming down from the motor now turns around that pin with very little friction and runs back up to a screw eye screwed into the fixed base just below the motor/pulley.

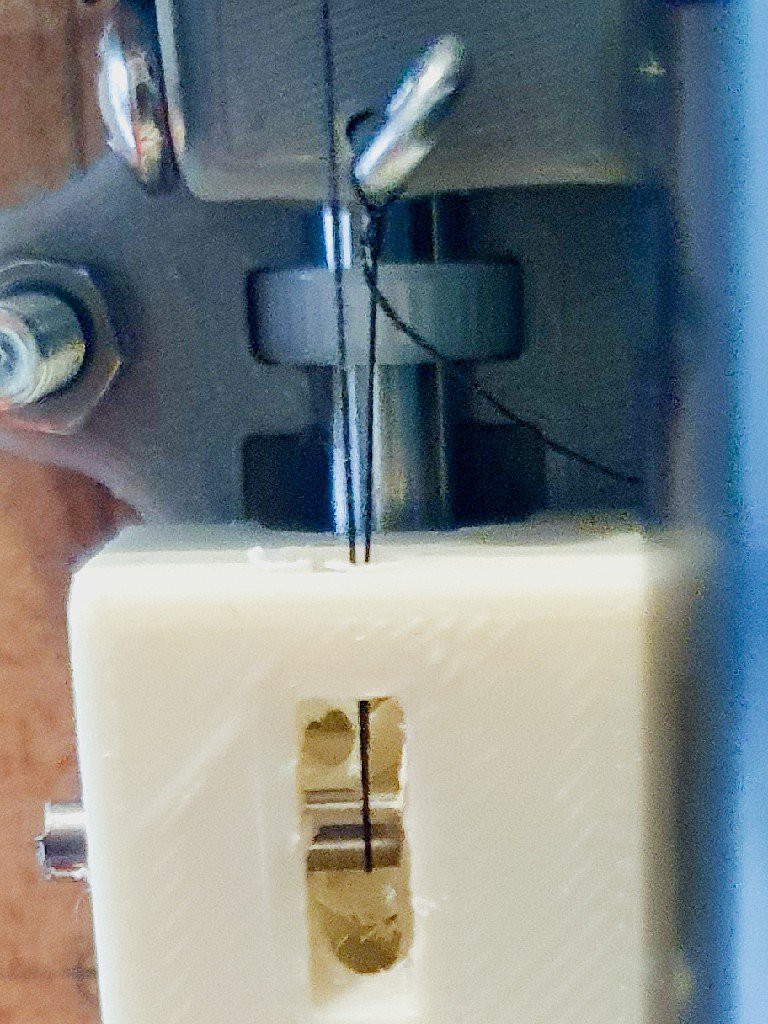

At last report on Discord, janvorli had cut a couple of flat spaces:

It may not look like much but the considerable victory shown there is that, after troubleshooting his heavier Z axis and my dual motor fallacy, the two flats are milled to exactly the same depth. Big win.

I think it's important to note that janvorli is the first, that I knew of, to wade into building the 3d printed version of this "Minamil" concept. So he bore the brunt of (not) finding what I hadn't written yet, and challenging the Z axis with a load that I hadn't actually tested for real. I appreciate his help to advance the documentation, and understanding of how the Z axis really works -- and what to try next for that.

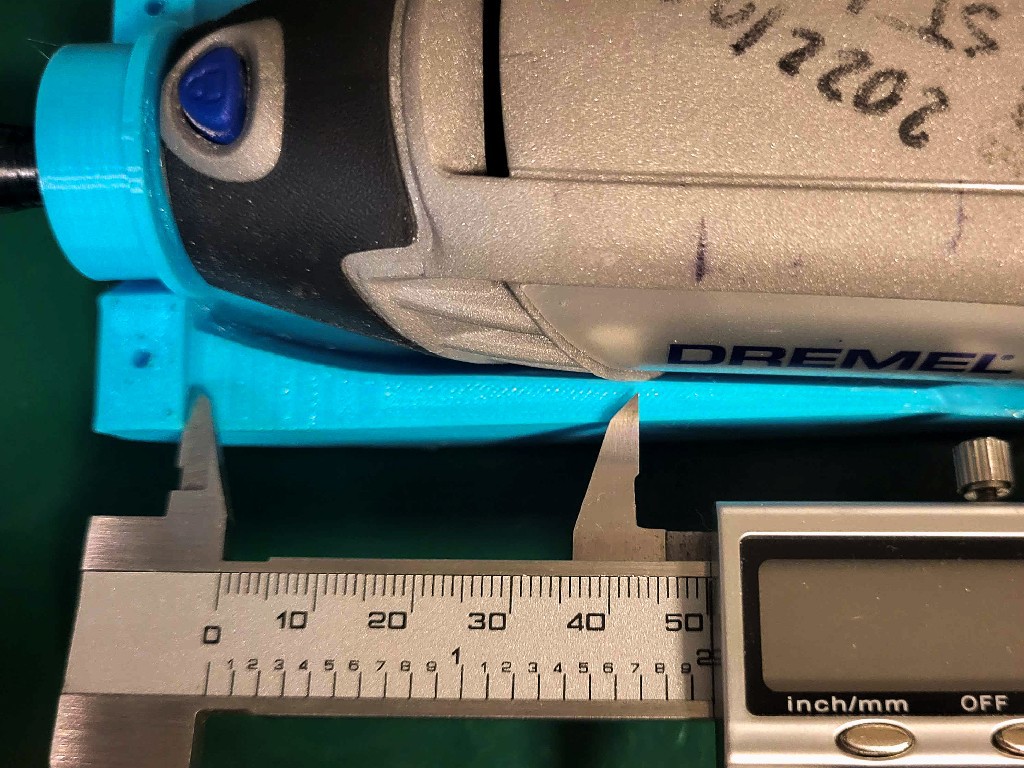

Meanwhile, Raf on Discord was building his own "Minamil" when he found that his Dremel 3000 didn't fit into the Z sled. He found a 3D model of the tool that I could use in lieu of the real tool in hand, and we had some back-and-forth about adapting the tool clamp to fit. Almost:

Then a friend of his with relevant CAD skill grafted a suitable clamp onto the base of the Z sled STL to put Raf in business. Raf also shared the new STL back to Discord. A more responsive me would already have all these modified tool clamps uploaded to the HaD project files. So please ask if you have need and don't feel like combing through Discord history. (But hey, join the Discord party anyhow!)

And here's Raf's built machine:

Yeah, the tool body clamp broke. He says it's working ok with just the nose clamp.

He too has both Z motors rigged. If we've understood janvorli's case correctly, that works for Raf, and my earlier trials, because it doesn't really need both motors to lift the spindle, so it's less vulnerable to differences between theory and reality of load sharing as currently implemented. ...more about that in the other log entry that I haven't written yet.

Raf's uploaded filename "minamil_first_try" suggests this is his first result:

Nice! I think that's a pretty big deal, in my view of the project, that someone who's not me has actually in fact worked thru the how-to write-up, such as it is, and put together a replica that, apparently, worked well enough to produce something near to intended results on the first try. Plus adapting the Z sled for a different "spindle" tool along the way.

Bravo Raf!

Both janvorli and Raf have built "corner" frames with the Z axis at 45° to the base. I feel a bit like a bad influence setting that example on my overwrought quest for compactness when a "square" frame (I.e. rectangular, like these examples of the laser cut version) would be the easier, more direct path to a working result. Anyhow, congrats to janvorli and Raf for results achieved!

I'm looking forward to seeing what they do next. How about you?

Paul McClay

Paul McClay

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.