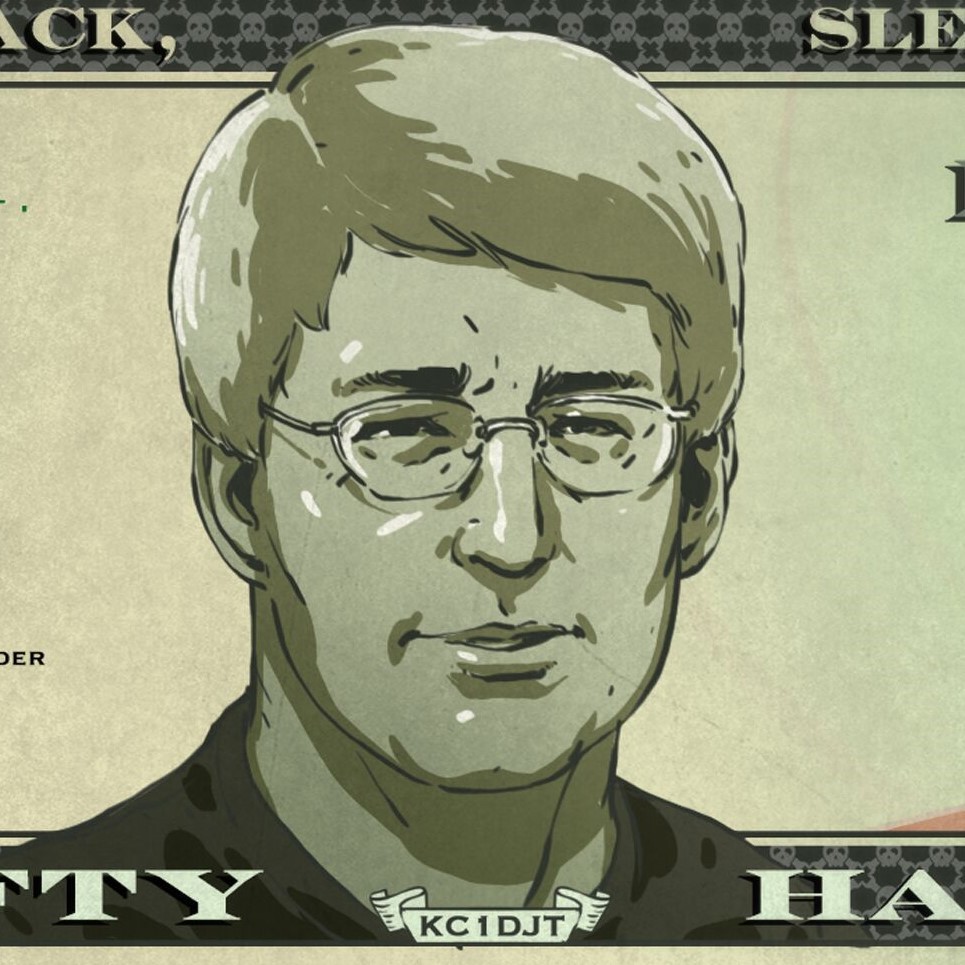

Gabe Bentz will host the Hack Chat on Wednesday, August 23 at noon Pacific.

Time zones got you down? Try our handy time zone converter.

We'll take a wild guess and say that right now, within arm's length of wherever you're reading this, there's something that was produced by injection molding. Look around; it's there someplace, and whatever it is, thousands or perhaps millions of other identical artifacts were produced along with it, all by squeezing hot plastic into intricately machined metal tools.

It's not much of an overstatement to say that, for good or for ill, the world is made from injection-molded plastic. But not every product can support the often considerable up-front costs associated with injection molding. The tooling needed is often remarkably complicated and correspondingly expensive, and running the machines that actually do the molding is expensive and highly specialized. Unless you're committed to making a lot of parts, injection molding might just be out of your league.

But does that mean that medium-sized runs of parts are out of luck? Not at all! Gabe Bentz, founder and CEO of Slant 3D, is passionate about filling the manufacturing void where injection molding is prohibitive, either by virtue of start-up costs or because the part design is just not possible to manufacture. His massive print farms are busy day in and day out cranking out parts for customers that otherwise couldn't be made. So if you've ever wondered what it takes to run a print farm, and what kinds of design considerations make a part a candidate for mass production by 3D printing, drop by the chat and we'll see what he has to tell us.

Injection molding is everywhere, but it’s not always feasible for everyone. Enter 3D printing! Gabe Bentz from Slant 3D is filling the gap for those who can’t afford the high costs or complex designs of traditional methods. Looking forward to hearing how his print farms are changing the game!