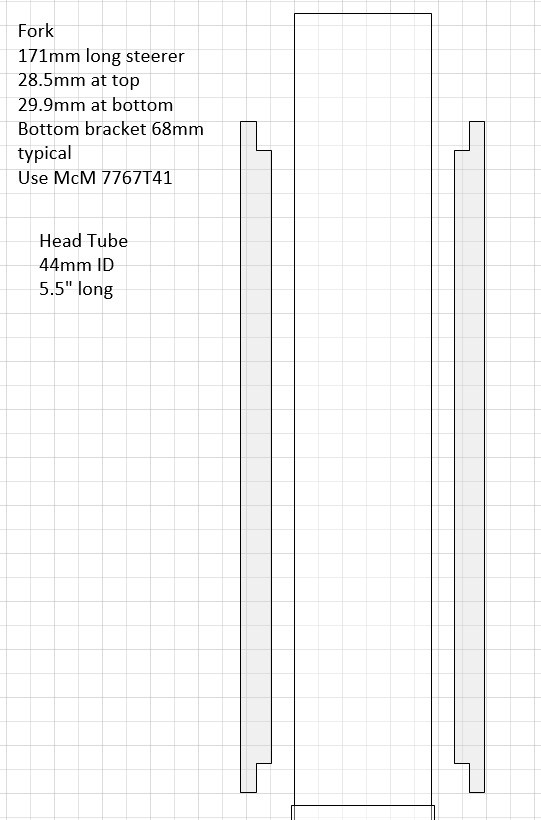

First I had to make the head tubes (tube which forks go through). Matching the bearing diameters to available tubing meant buying 2" diameter tubing with 1/4" thick walls. These should be strong.

The raw material, with a Sharpie for reference

Turned both, one has bearing pressed in. While I had them on the lathe I sanded them a bit too.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.