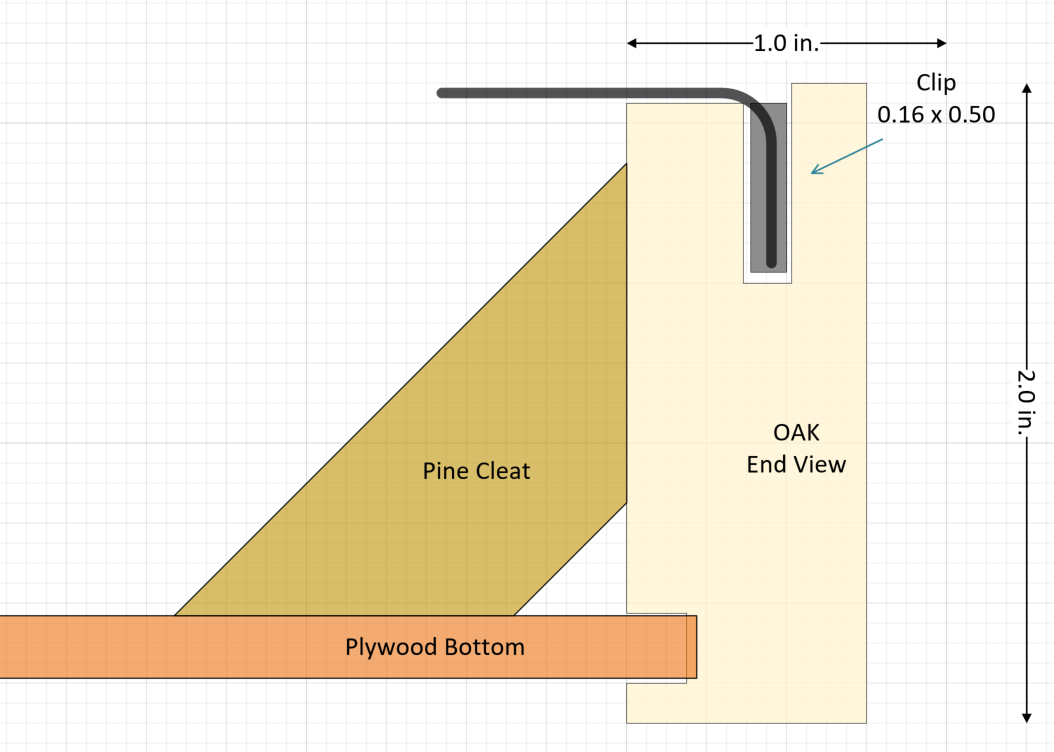

I think we are at final revision for the seats. What had happened was the tensioning on the upholstery straps, perhaps 80 pounds each or so, was enough to either warp the bottom, warp the side, and even both. So a two-pronged approach was decided: make the seat so strong it won't warp, and add cross woven straps so each strap does not require so much tension. Also, switch from stapled straps on the wood side to proper metal clips in a thin dado. This are sometimes known as Pirelli Clips. Below is a diagram.

This is the glue up of one of the seats. It's nice that the spring clamps did a good job of pulling the cleats in diagonally. the cleats were cut after the frame was installed, each trimmed to the right length.

One of the pieces I had chamferred a bit for clearance, whcih I thought was good. No bueno. In a couple places where the chamfer was a bit deep (due to slightly warped wood) the clips tended to pop out. That was fixed by trimming a toothpick to 2", and using CYA (crazy glue) to adhere it to the chamfer. Then I added more glue and used baking soda as a filler. This took just a couple minutes, saving many hours of rework.

The open frame, frame with webbing, and finished seat with 2" foam and marine vinyl is shown below.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.