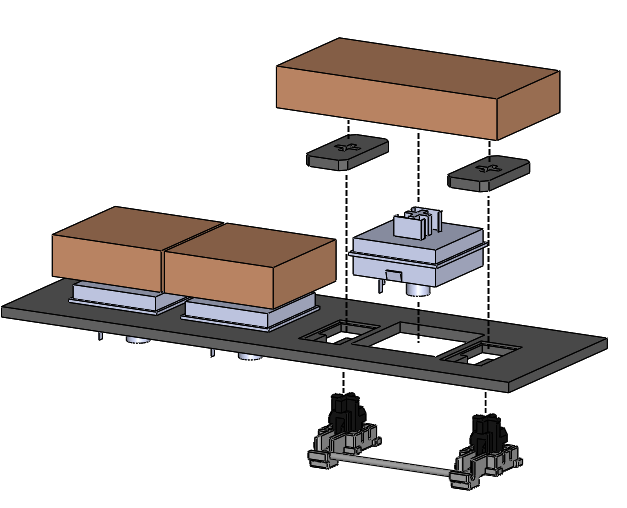

Before jumping straight into a full-scale keyboard, I made a small scale version of the parts that required some troubleshooting. This smaller test had 3 sets of key switches/keycaps and a set of keyboard stabilizers for the wide key.

For creating the custom parts, my design process was:

- Create a complete 3D CAD model of the full keyboard

- Based on the 3D CAD model, create 2D DXF files for the individual laser cut parts.

- Cut parts with laser cutter

- Tune laser cutter parameters and use hand tools to match 3D CAD model. Tuning parameters are necessary for anything that is snap fit. Hand tools are used to remove burn marks from the laser cutter.

Because of this process, the DXF files and STEP files in the project files won't match. The differences are either due to laser cutter kerf adjustments or purposely made bigger so there is material to finish with hand tools.

A zip file is added in the project logs that contains a STEP file of the entire assembly and individual DXF files for 3 of the parts that were laser cut. The following few logs will detail the making of this 3 key tester.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.