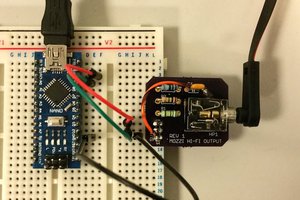

Let me know if you have questions or suggestions! I'll be adding more info, including a wiring diagram soon. This is a kalimba(or thumb piano/thumb drum) with an internal contact mic, a Teensy 3.2 w/ attached audio board, and knobs for effects modulation. It has jacks for mono 1/4" guitar output, or stereo 1/8" headphone output. The code I have running now has a very basic set of 4 effects knob: delay, low pass, bitcrunch, bitcrunch samplerate. Thanks SO MUCH to Paul Stoffregen for his work making the Teensy and audio board for it.

Electric Kalimba

A handheld instrument made with steel tongs. Uses a teensy for audio effects.

thesage1014

thesage1014

arturo182

arturo182

Matt

Matt

Pontus Rodling

Pontus Rodling

Ben Holmes

Ben Holmes