How the clock is supposed to work was made pretty clear from the videos that I found on YouTube. The whole mechanism is keyed off from the marble lift wheel that make one revolution per hour.

- As the wheel goes around it will pick up one marble from the bottom marble storage ramp ( in the slightly offset lead hole). Then the wheel will pick up all the marbles in the upper teeter totter accumulator ramp in sequence into the outer holes as they rotate past the ramp.

- As the holes in the lift wheel reach the top the marbles are allowed to exit onto a ramp at the back. The marbles roll down and around the ramp to stack up in the front of the clock at the trip arm's marble stop.

- As the minute hand approaches the 12 o'clock position, the cam follower on the trip arm is activated so that the marble stop on the trip arm allows a marble past to be held back by the secondary stop on the trip arm.

- When the minute hand reaches the 12 o'clock position, the trip arm cam follower is allowed to reset, letting the advanced marble proceed down the ramp and restraining the rest of the marbles in the train.

- As the released marble rolls down the ramp it will again depress the trip arm to allow the next marble to be advanced to the secondary stop position.

- When the marble exits the ramp it will ring the gong and release the advanced marble to proceed down the ramp to continue the eventual release of all the marbles in the train. The length and angle of the ramp greats the delay between the striking of the gong.

- After each marble triggers a gong strike it is directed into the upper teeter totter accumulator ramp. The teeter totter is balance so that it remains angled down towards the lift wheel until the 12th marble is added to the teeter totter.

- When the 12th marble is added the teeter totter tips over to release all 12 accumulated marbles to be directed to the bottom storage ramp, thus restarting the process for the next 12 hours.

Tipping ramps are used in a lot of marble kinetic sculptures, but combining it with the lift wheel creates a mechanical adder/accumulator with a reset.

The time keeping portion off the clock is regulated by a 1 meter (1 second) pendulum and a Graham Yoke escape wheel with 30 teeth, resulting in one revolution of the escape wheel per minute. A drive train reduces the escape wheel's revolutions by 60 to rotate the lift wheel (and the minute hand) once per hour. A second 12 to 1 drive train hangs off the axle off the lift wheel to reduce its revolutions to once per 12 hours for the hour hand. The second drive train is free hanging and uses a weight to keep it vertical.

Simple huh?

I just needed to create a version that could be 3D printed, not to difficult right?

Time to fire up FreeCAD.

You can find the all the FreeCAD files on GRABCAD.

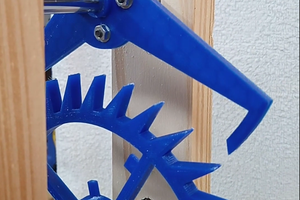

Armed with the marble size (16mm) and the printer bed size (300x300mm) I set about designing the clock. After iterating through various design choices I've come up with a design that I think has a good chance of working, I just need to print out a few test pieces to see if my design choices will work. Most notably the Graham Escapement, the Teeter Totter rail, and the marble lift.

Over all the design uses 5mm axles and flanged F695 bearing for the pivot points except for the lift wheel which uses an 8mm axle and 608 bearings. M3, M4, and M5 thermal inserts along with appropriate screws are used to fasten the various pieces together. Parts were designed to be printed with minimal or no supports (I really don't like using printing supports unless I have to).

A few of the more interesting design elements are as follows:

Some of the YouTube videos showed the marble lift wheel being manually rotated (to show how the mechanism worked) without the pendulum, nor the yoke swinging. This indicates that the Graham Escapement they used has a position that allows the escape wheel to freely rotate. I don't like that option so the...

Read more »

Steve

Steve

rkramer

rkramer

John Opsahl

John Opsahl