Introduction

In this log we will take a look at the resistive plate PCB, see it's functionality, where it sits in the assembly, and how it was assembled. Lastly I'll go over the lessons learned.

Resistive plate PCB

This pcb serves 4 main functions:

1. It controls the resistive touchscreen through the TSC2046 chip

2. It serves as a strucutral support that holds the resistive touchscreen, and the adjacent elements.

3. Anchors the middle hub, which serves as the holding point of the universal joints

4. It houses a 6DoF IMU as well, to be able to tell which angle does the plate sit relative to the gravity vector.

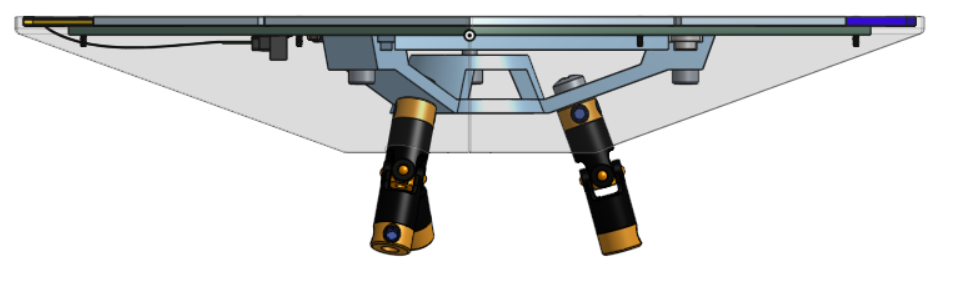

CAD view of the resistive plate pcb

here you can see how the PCB contributes to the top assembly. (the green hexagonal part)

PCB assembly

The chosen IMU (LSM6DS3TR-C) had a leadless package, and a very fine pitch. I didn't feel comfortable soldering it by hand, so I tried out for the first time stencil soldering. At the end it turned out better than I expected it would, however I did have to touch up the connectors by hand. I recorded the process, so please enjoy this short video of the process:

Let me know in the comments if I should improve the soldering process.

Lessons learned

- The PCB manufacturer quotes the PCB based on size, so using the PCB as a large structural element might not been the best choice. In the future it's best to keep the PCB as small as possible, and use other material for support.

- The threaded anchors rip the copper off easily from the PCB, so I had to glue them in position, which helped at the end. It's a good lesson again not to use PCBs for structural support.

Summary

Over all the resistive plate PCB will be an important part of the build, and now I have a working prototype of it.

Tamas Feher

Tamas Feher

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.