As i wrote in my first log, is necessary to turn the upper bar at a constant turn rate.

Let us first take a look at a isosceles triangle. Thinking about a barn door tracker, we could assume, that the two fixed length sides would be about 40 cm long. The variable side (the threaded rod) will be adjustable between 0 cm and 40 cm. The first case of 0 cm gives us an opening angle of 0°. The second case will form a equilateral triangle, which will lead to a opening angle of 60°.

Assuming that the earth rotates at 360° per 1440 minutes, it will take 240 minutes to open the tracker by 60°. Side c (the rod) needs to be extended at 6 minutes per centimeter.

![]()

Any other angles can be calculated as:As the movement of the upper bar is constant, we can insert another data point at 30°.

The first 30° section, between 0° and 30°, need to take 120 minutes. At 0° the rod will be 0 cm long. At 30° the rod will be 20.71 cm long. Which gives us a movement rate of 5.80 minutes per centimeter:

The second 30° section, between 30° and 60°, will also take 120 minutes. At 60° the rod will be 40 cm long. Which gives us a movement rate of 6.22 mintes per centimeter:

As you can see, the rod needs to move slower in the upper 30° section than in the lower 30° section.

Now we'll split the 60° opening angle into 5° segments, where each segment will take 8 minutes:

| start angle | end angle | length change in cm | min per cm |

| 0 | 5 | 3,49 | 5,73 |

| 5 | 10 | 3,48 | 5,74 |

| 10 | 15 | 3,47 | 5,76 |

| 15 | 20 | 3,45 | 5,80 |

| 20 | 25 | 3,42 | 5,84 |

| 25 | 30 | 3,39 | 5,90 |

| 30 | 35 | 3,35 | 5,97 |

| 35 | 40 | 3,31 | 6,05 |

| 40 | 45 | 3,25 | 6,15 |

| 45 | 50 | 3,19 | 6,26 |

| 50 | 55 | 3,13 | 6,39 |

| 55 | 60 | 3,06 | 6,54 |

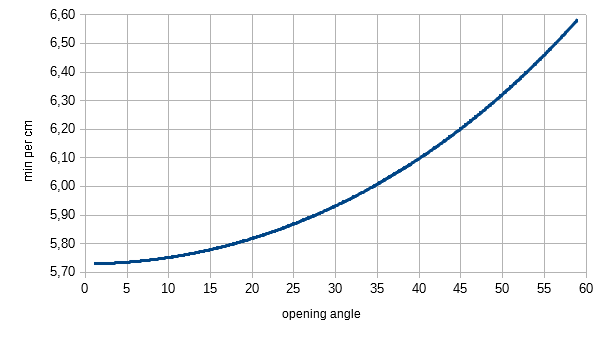

or as a diagram

This makes it clear, that the rotation rate of the stepper needs to be adjusted on a regular basis.

As a last step, we will convert the length change of the rod into steps per second.

I'll use a TR 12 X 3 rod, where one turn will cause a length change of 3 mm. The stepper has a resolution of 0.9° per step. So each step will change the length by 0.0075 mm.

To change the rod at a speed of 5.73 minutes per cm, the stepper needs to make a step every 0.258 seconds.

At at rate of 6.54 minutes per cm, that value changes to 0.296 secondes per step.

MughtyWinky

MughtyWinky

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.