Next up was a bit of experimentation as how to solder this; without ruining colour. Using a relatively hot SMD oven caused a slight browning of the imagery. The same was found when using a hot air gun indiscriminately.

Normal traditional soldering; or gentle hot-air in limited areas worked well - with no discolouring discernible. The one exception was near the USB-C connector. One needs to really heat this up to get the solder to flow well enough for a good mechanical fix (future versions probably should simply use two power pins; rather than USB to prevent this).

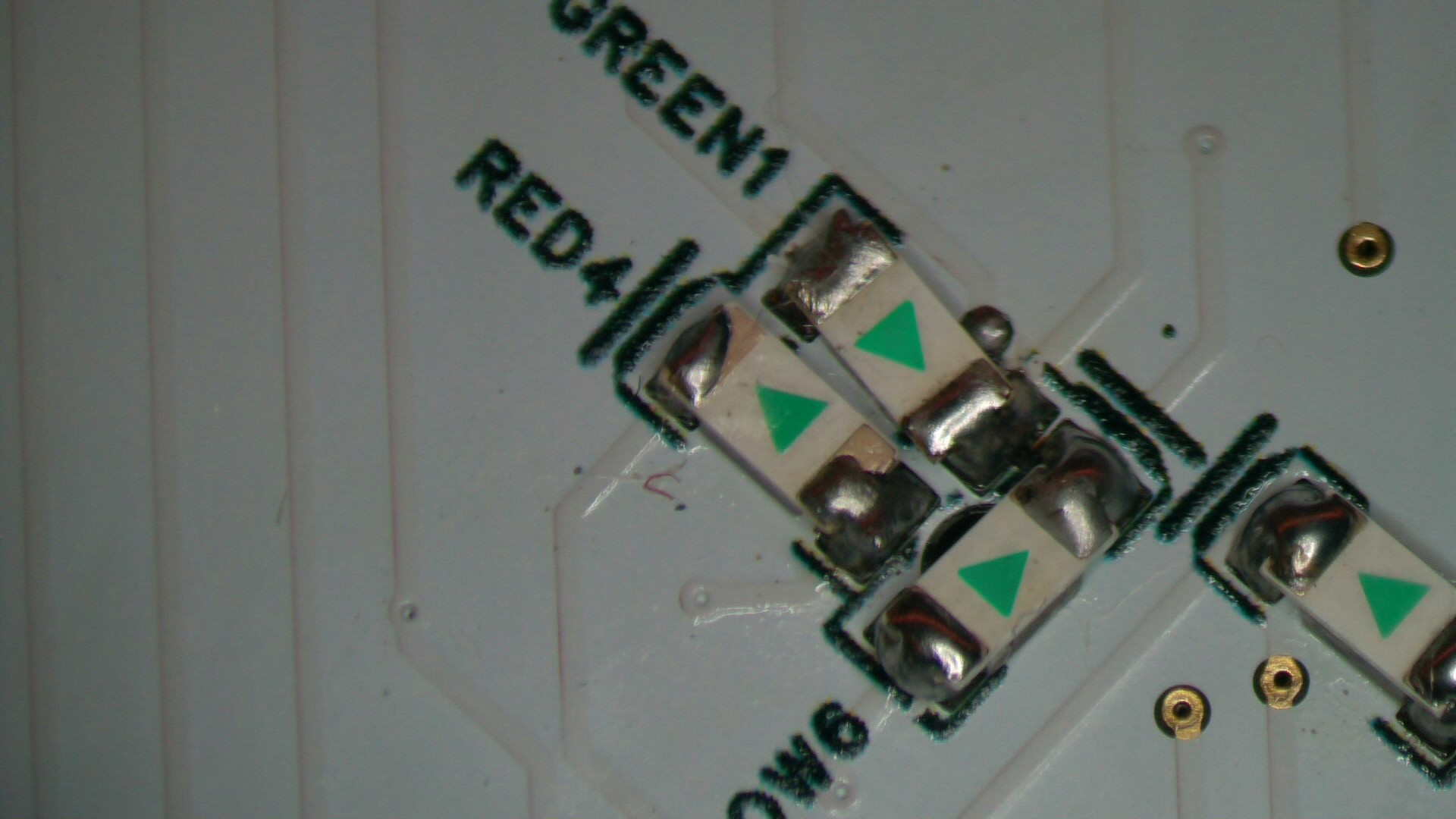

The reverse LED soldering was slightly more challenging. As we wanted them to be `on top' of the PCB - rather than `fall' through a square hole.

Turned out this was best done by putting a small blob of solder on one side; hold the LED against it; solder that one side; then let solder flow under the older side. And then complete the first side.

Dirk-WIllem van Gulik

Dirk-WIllem van Gulik

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.