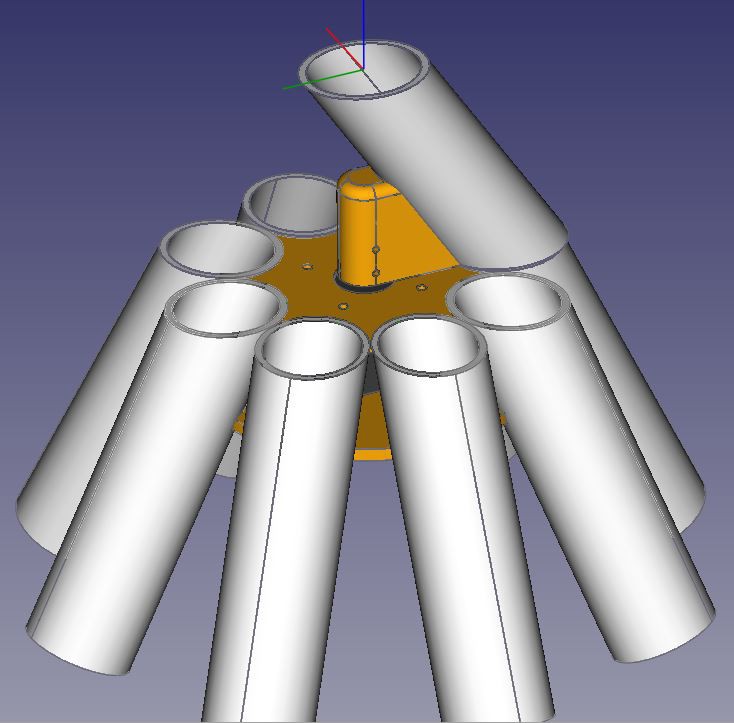

Some initial CAD work on the diverter...

Design goals:

- eight ouput tubes

- NEMA 17 motor

- minimise moving mass so that it can start/stop/move quickly between positions

- keep transit path short so that pieces are processed quickly

- minimal parts count - use 40mm pipe, 3D printed parts and adhesive only - just a few screws.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.