Working on the back of Mechanical Stuff project log; we worked on giving the caliper's T-scale a solid backing to create a stiff backing.

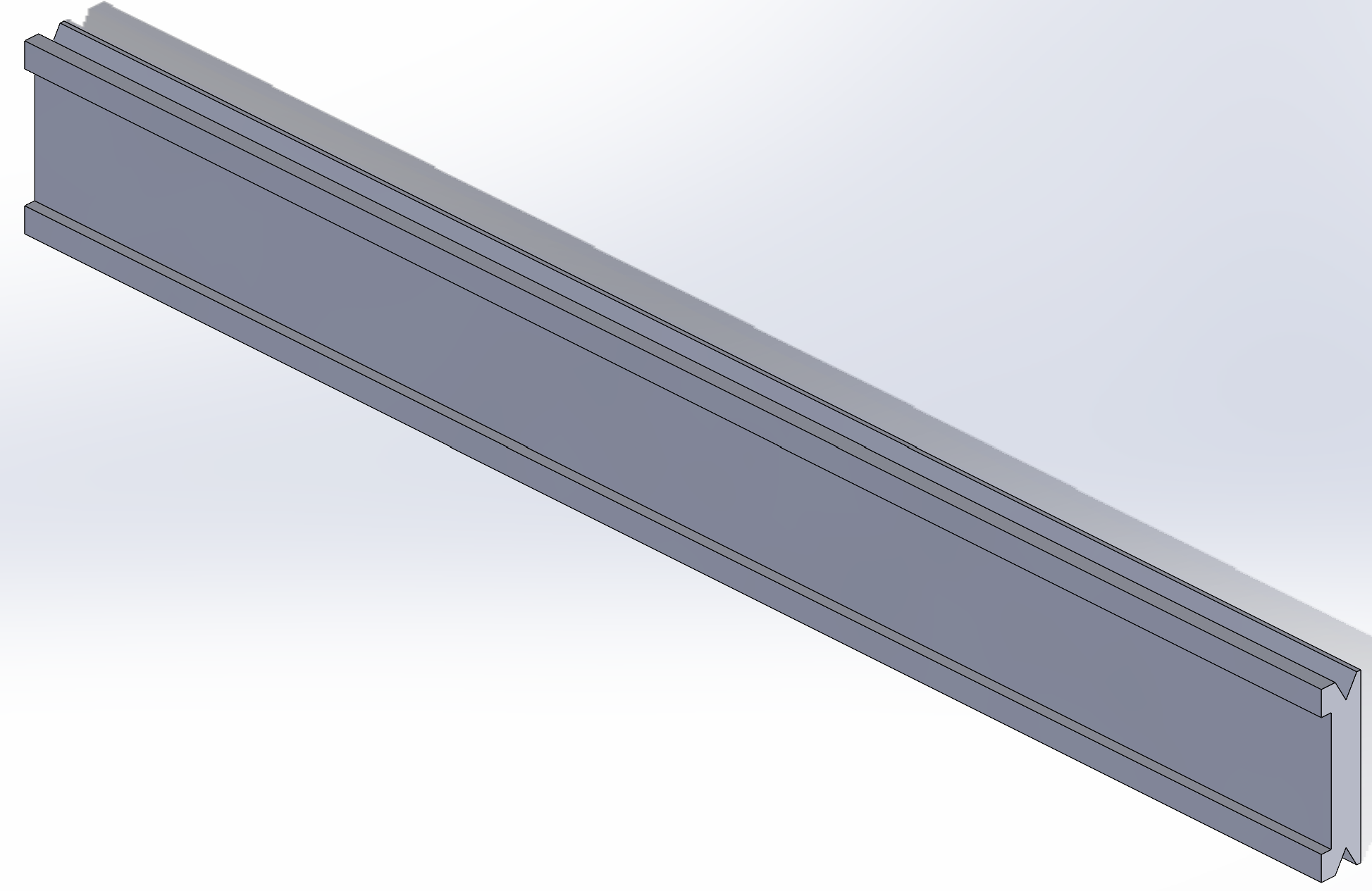

We started with the idea shown below but it was going to be a expensive part to machine given the 3 faces that would be machined.

Overly Complex Rail/T-scale backing

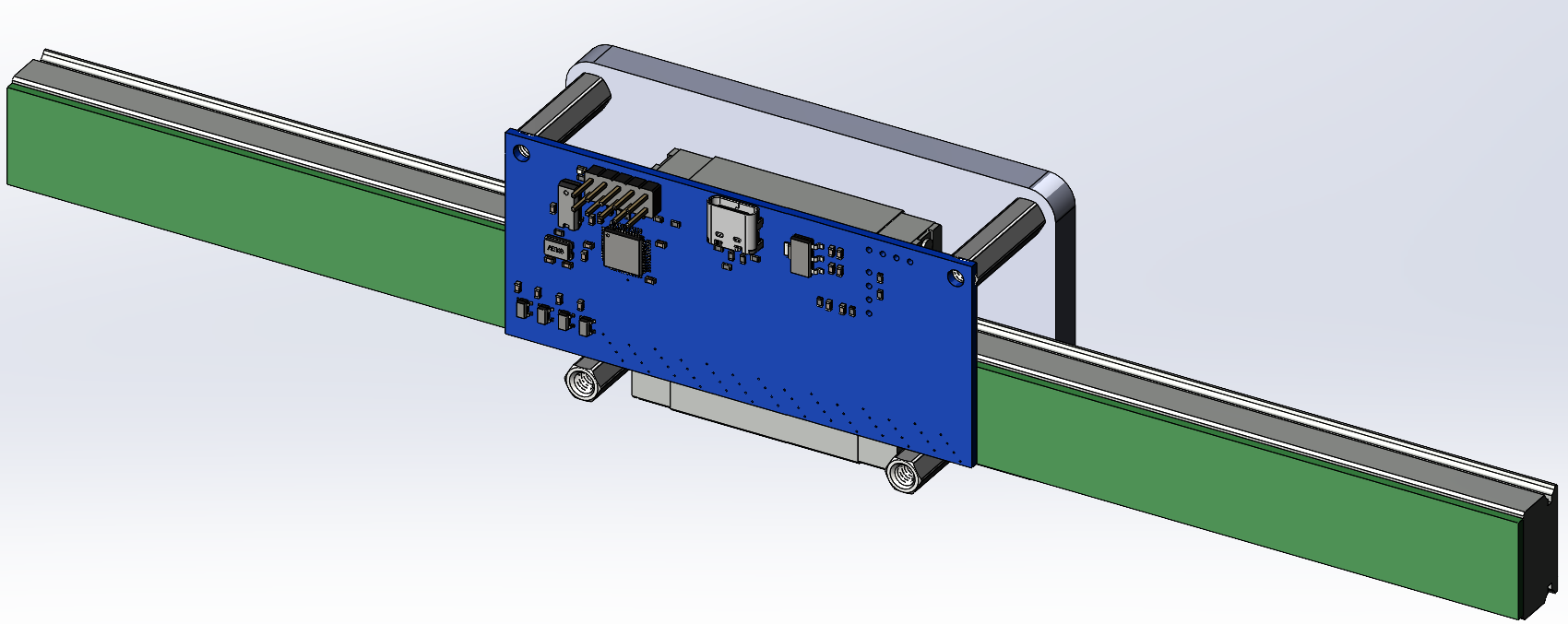

Given that we wanted a slider and rail set up, we didn't re-invent the wheel and I did a mock up for an assembly using a linear rail. This would provide a cheaper and higher tolerance slider and rail then anything I could custom design. The assembly consists of 6 main parts; rail, slider, base plate, 4x posts, T-scale PCB (Green), and the caliper PCB (Blue).

The rail critical dimensions are wider then 18mm and thinner the better. Looking at Hiwin, THK, or Misumi to find a high quality linear rail.

We also need to figure a good way to adhere the T-scale PCB to the rail. It is possible that PCBway or JLCpcb has adhesive coated PCBs off the shelf, double sided tape, or super glue.

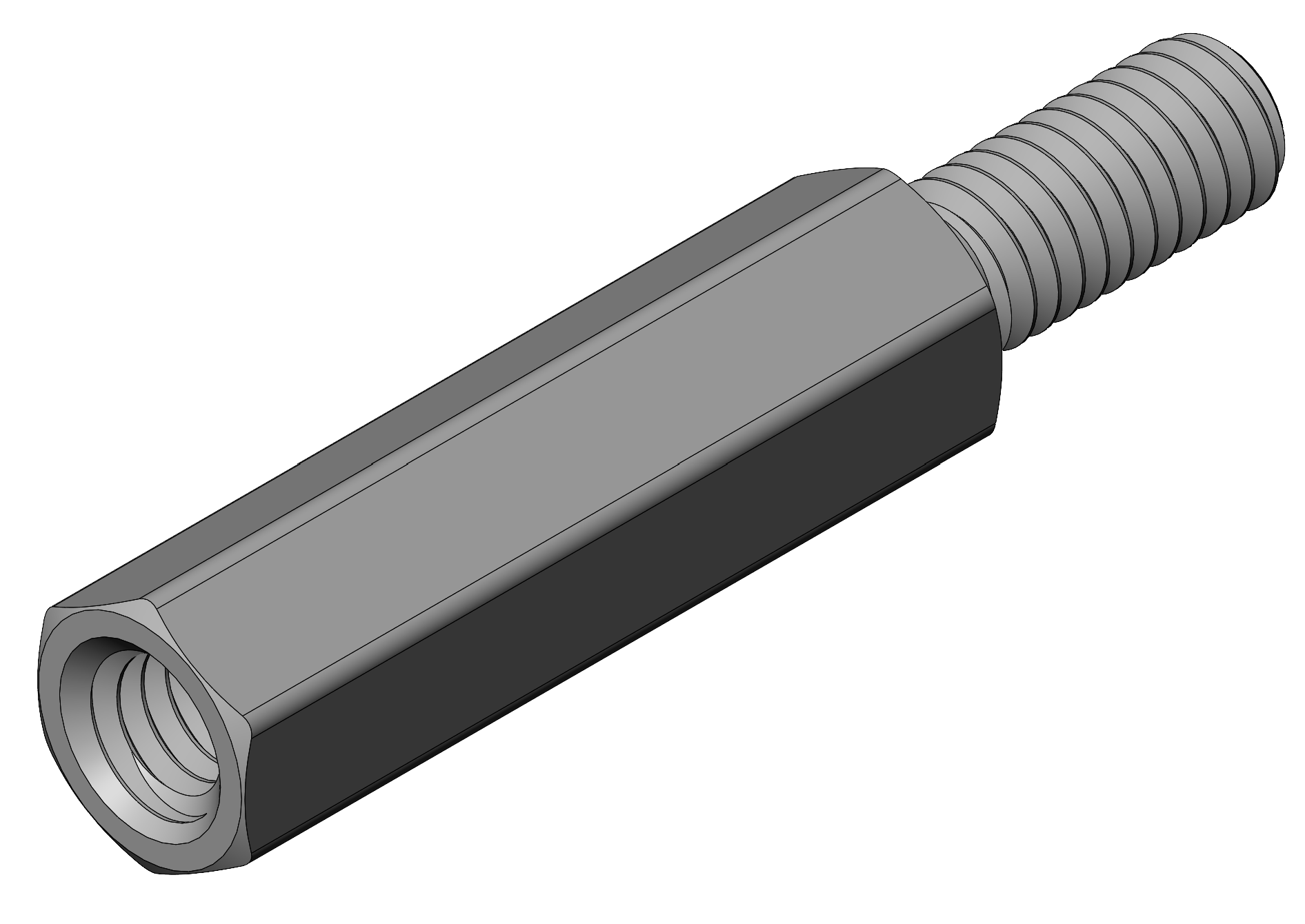

The posts shown below are from McMaster, part no: 93655A718 or 98952A065. These are the 22mm tall but might change to 21mm depending on what will work best.

The base plate is a planar part so it can be laser or water cut to make it cheaper part to machine. I want to see if we can get it made from Aluminum MIC6 given the greater flatness then most stock materials, although probably going to make it either from plastic or Aluminum 6061 T6. The position of posts on the lower half are closer to the linear rail's block to prevent any droop of the caliper PCB.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.