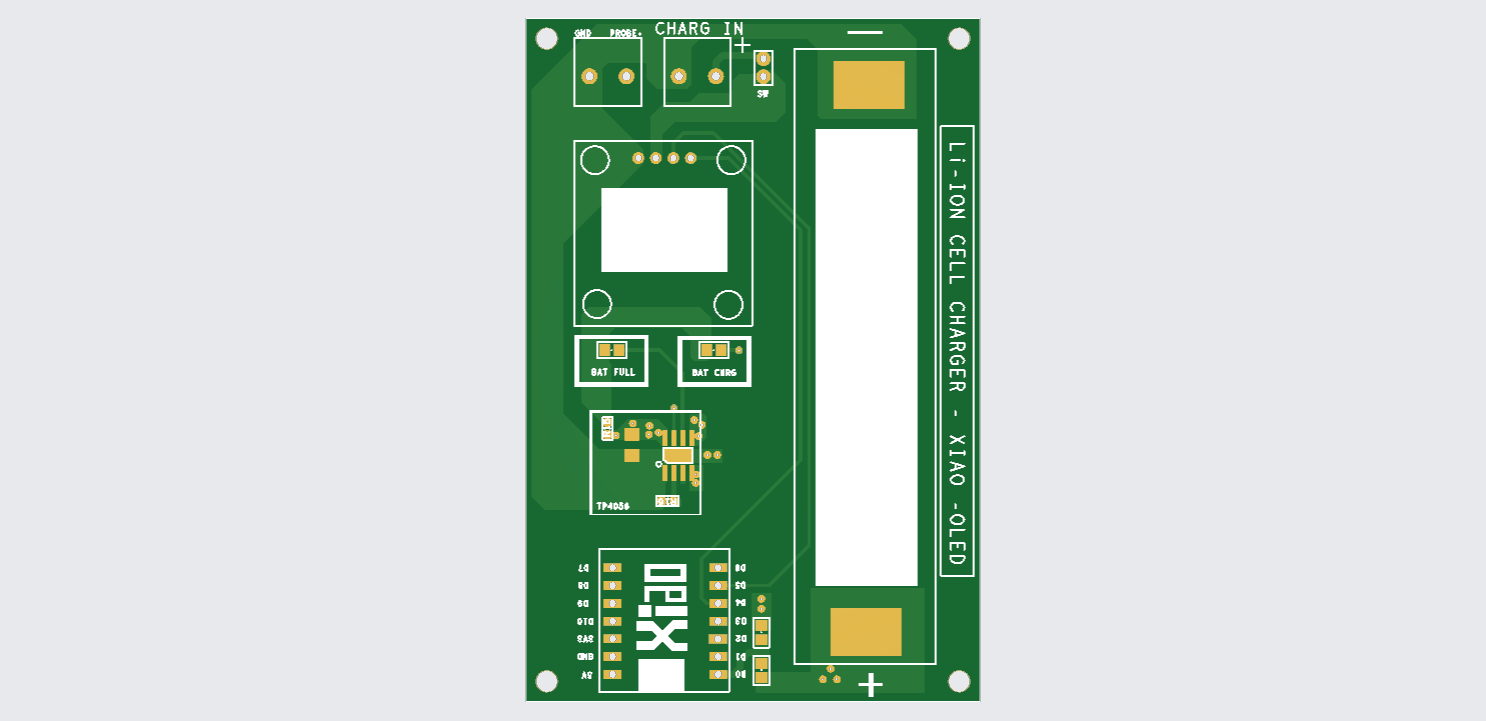

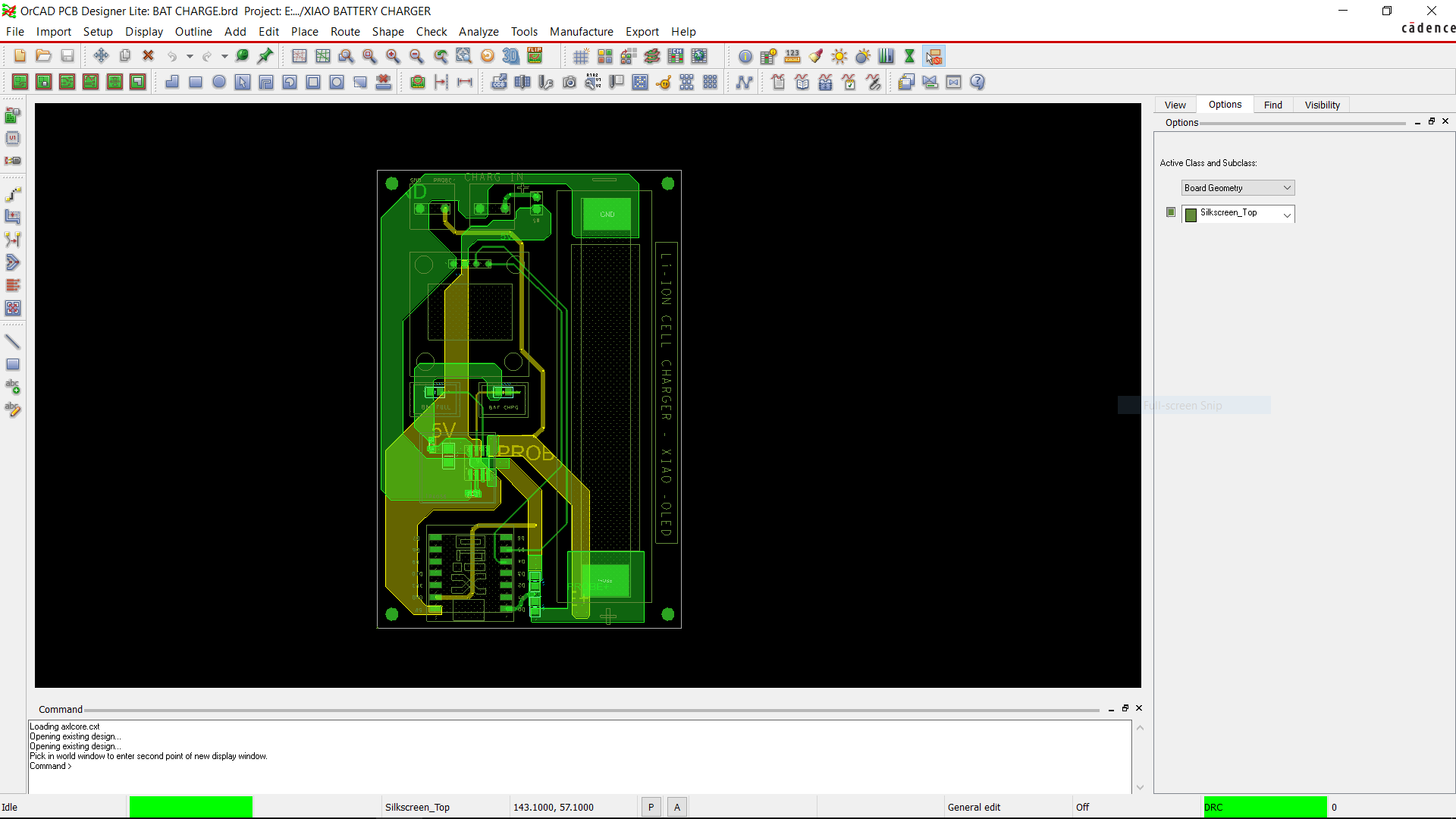

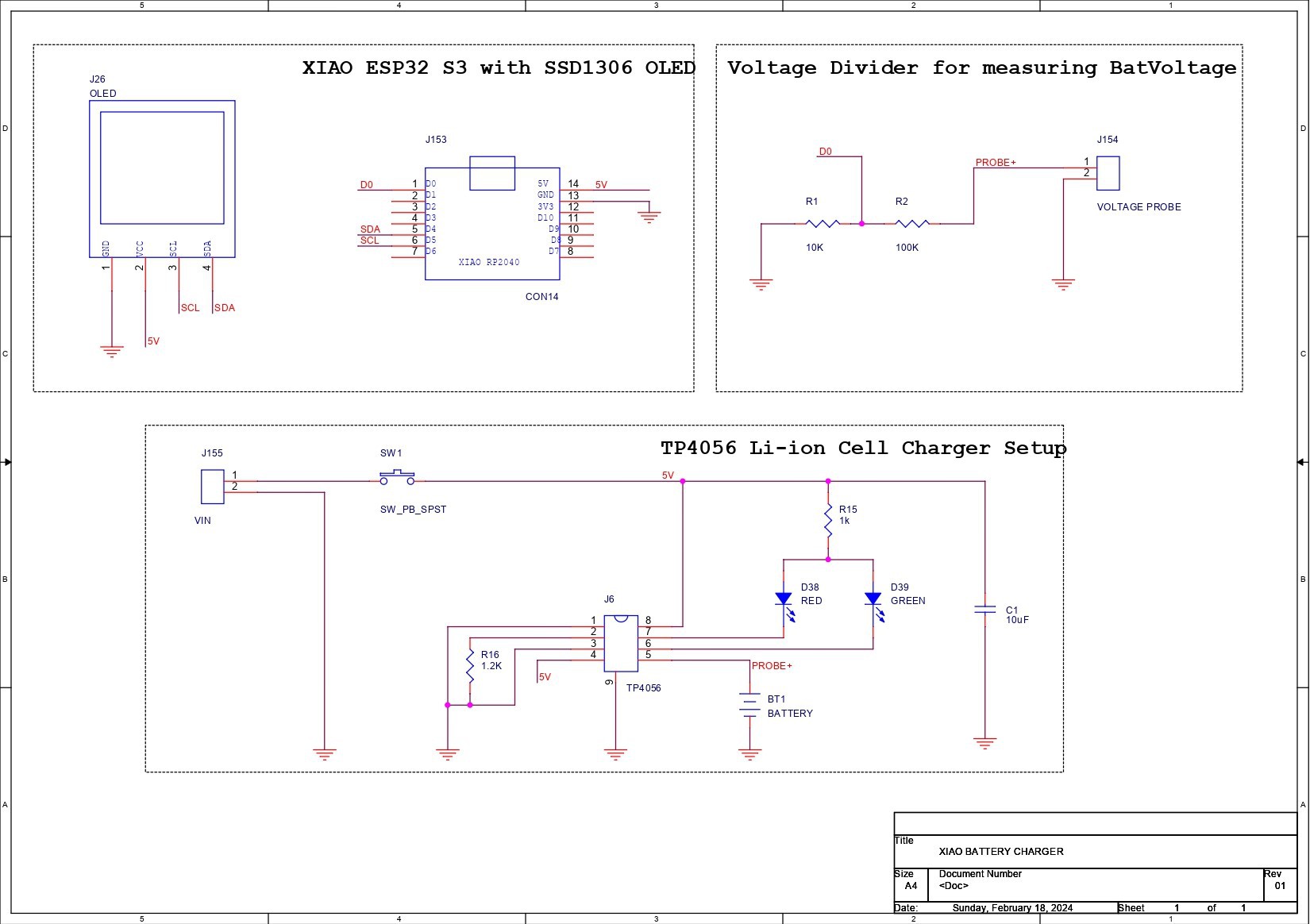

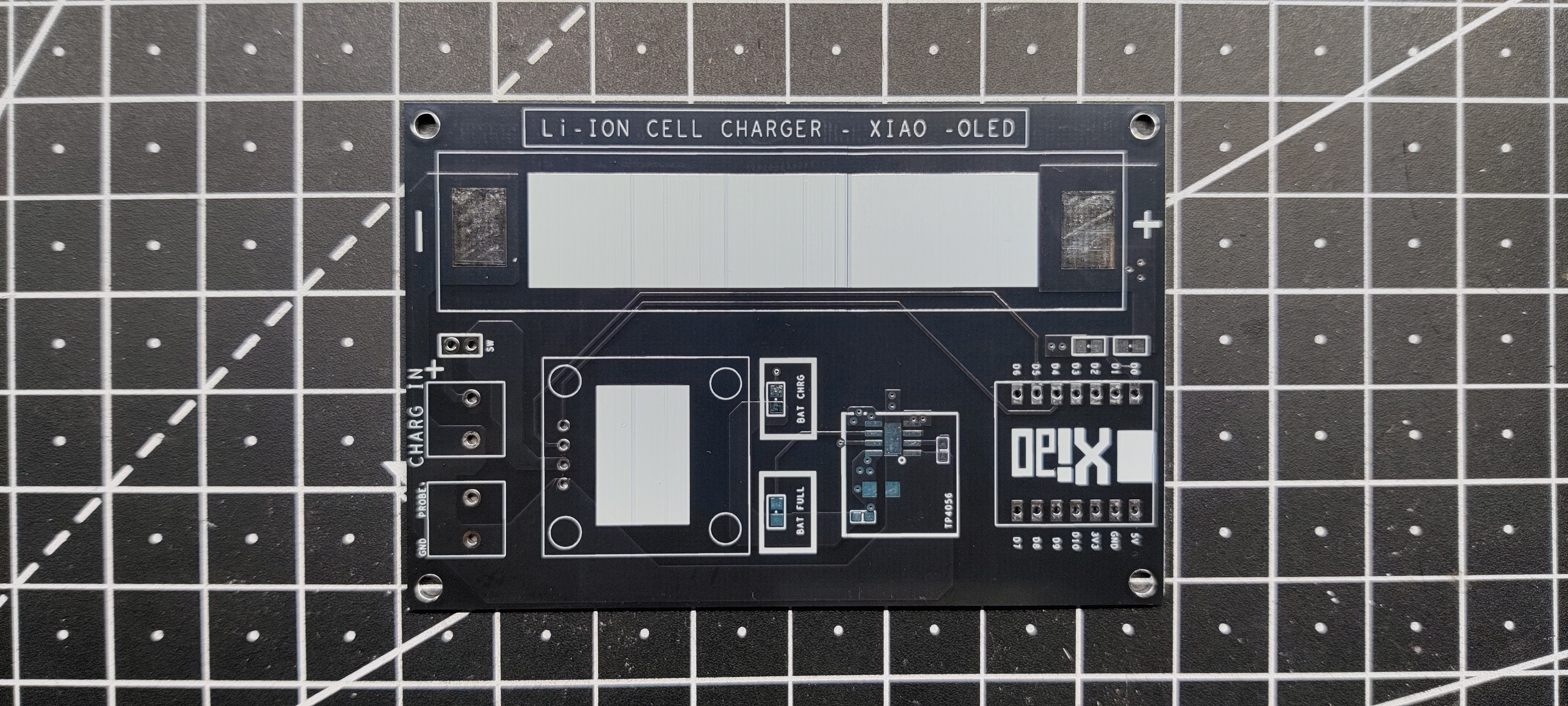

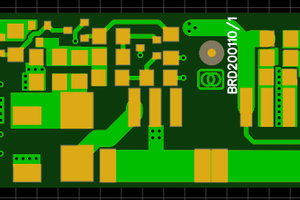

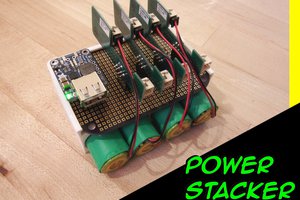

We are using the well-known TP4056 Li-ion Charging IC to charge the Li-ion cell. We are utilizing a DC-DC Buck Module to supply a stable 5V to this circuit. It does this by converting the 12V input side to 5V 3A or QC3.0, which is plenty to power the Li-ion cell. Moreover, it contains a few USB ports that can be used to power XYZ devices.

Essentially, there are two primary applications for this device: first, it charges Li-ion cells, which is very helpful because I have a lot of fresh Li-ion cells that are stored for a long time.

Since their internal resistance decreases after more than four to five months, we can simply put any low-voltage cell in and charge it to its operating voltage. Second, it offers steady 5V via USB ports, which is sufficient to power XYZ USB devices.

Arnov Sharma

Arnov Sharma

Lithium ION

Lithium ION

Christoph Tack

Christoph Tack

Manuel Tosone

Manuel Tosone

isaacporras

isaacporras