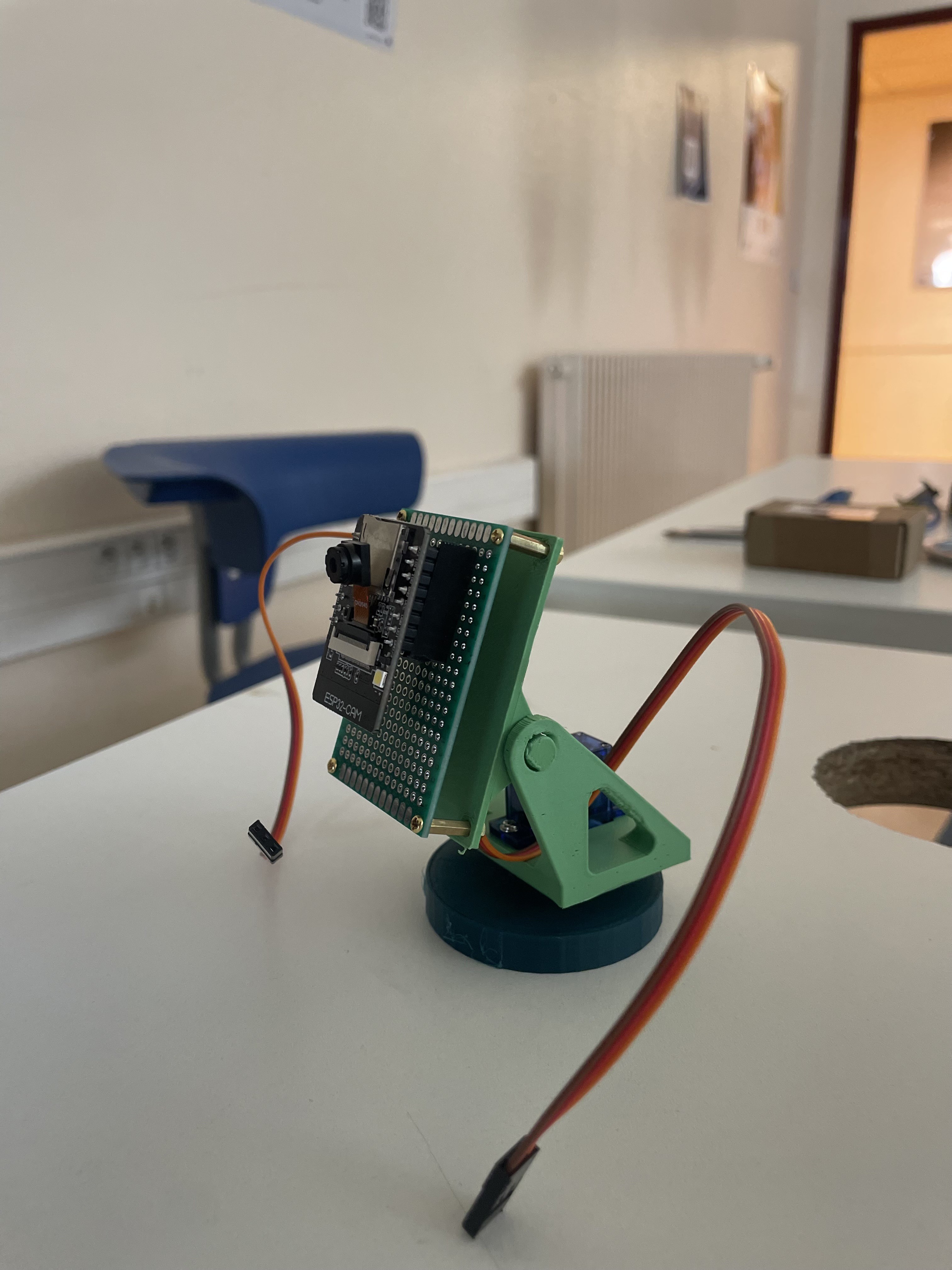

During today's session, our focus was on the assembly of the camera using the pre-fabricated 3D-printed components. Our first step involved meticulous sanding of these parts to achieve precise alignment and seamless integration. As you can see in the image below, we also redesigned the base of the device since having a circular base looks more professional and aesthetically appealing in our opinion.

First look at the Assembly of the camera

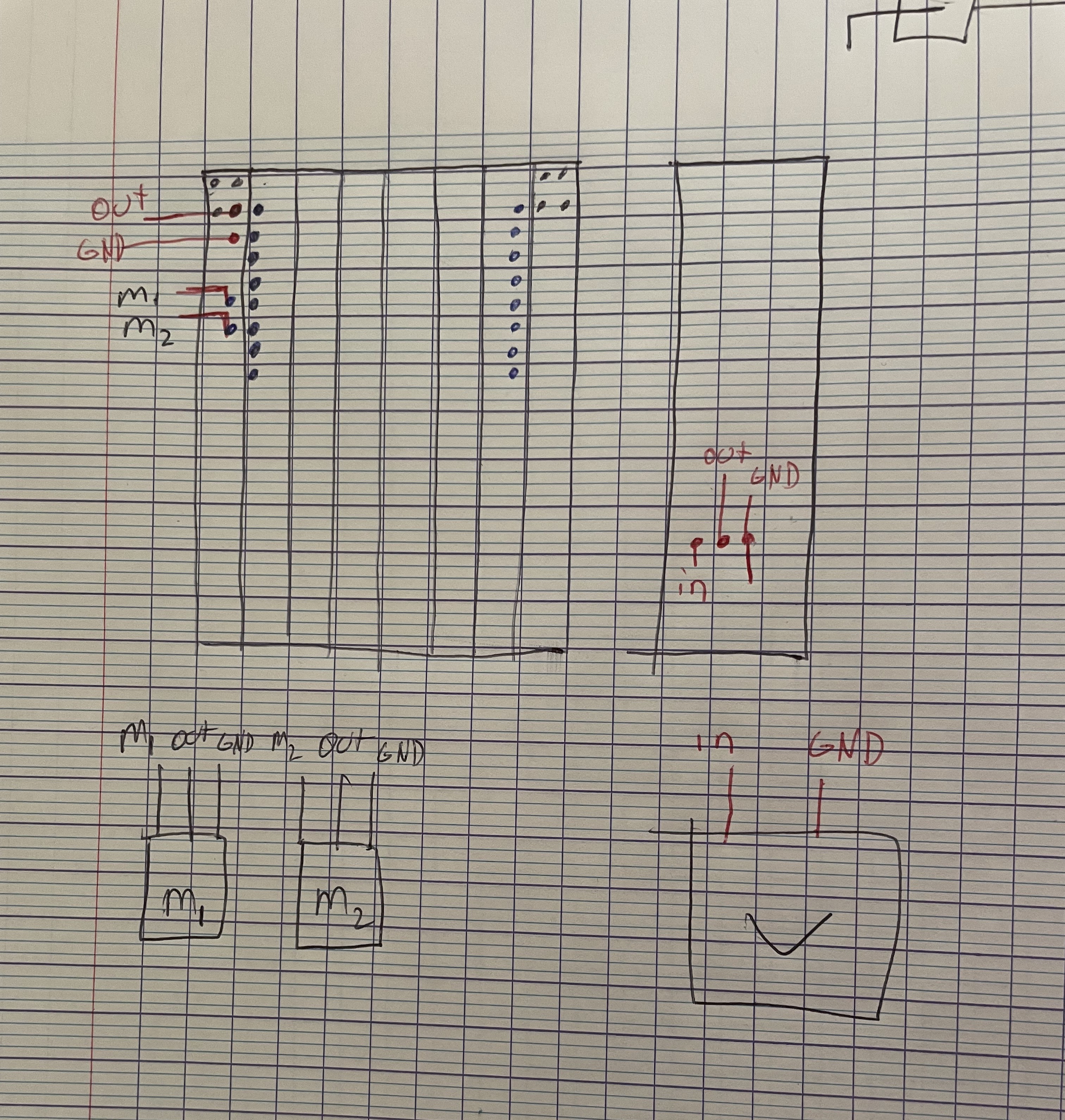

Following this preparatory phase, we proceeded to draw another comprehensive diagram delineating the structural layout and interconnections of the entire system. This schematic representation served as a vital roadmap for the subsequent soldering process. Each component and its corresponding electrical interface were meticulously annotated within the diagram, facilitating a systematic approach to the soldering task at hand. This planning not only ensured accuracy but also minimized the risk of errors during the assembly process.

Diagram of how the electrical components will be solded

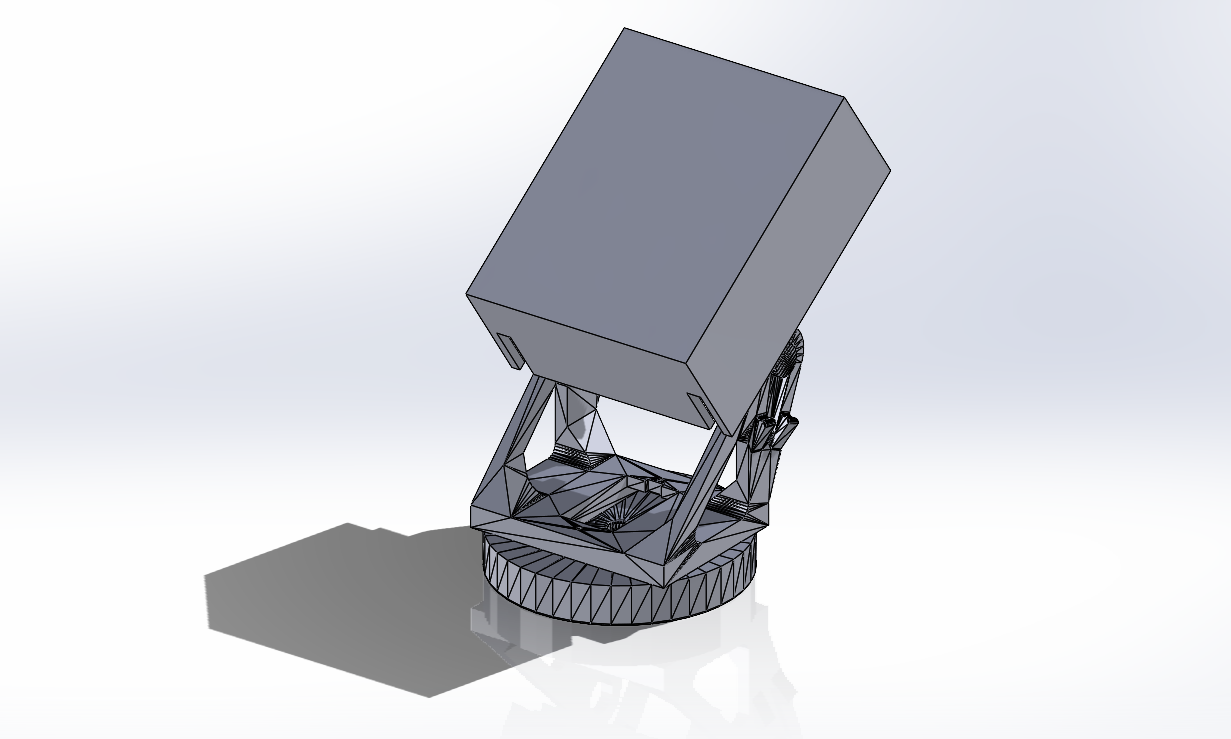

Additionally, we continued to work on the enclosure of the device. As mentioned in previous logs, we used the computer program SolidWorks to design it, making sure it had the right size so everything fits perfectly. In the image below there is the first look at how it's going. As you can see, to design this piece we started by assembling all the stls and continuing that we started designing the enclosure. This way, we could this design would cover the whole electronics but at the same time it wouldn't limitate the camera's movement ( see the lateral extrude cats for allowing the camera to tilt and pan). We will continue to work on this for the final product.

Camera enclosure

In summary, today's class was characterized by a series of deliberate and methodical steps, encompassing the sanding of 3D-printed components, the creation of a comprehensive schematic diagram, and the meticulous execution of soldering tasks. Through careful planning and execution, we successfully advanced the assembly process, laying the foundation for a functional and robust camera system.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.