During today's session, we continued to refine the design of the 3D prototype created in SolidWorks. In this session, we observed that rounded edges should be applied to the inner part due to their excessive sharpness. Consequently, we made the necessary adjustments to round them off, ensuring they would not cause any harm to Diego's hand.

Additionally, we brainstormed ideas to enhance the device's comfort further. This brainstorming session led to the decision to incorporate a layer of fabric in the area where Diego's hand comes into direct contact with the device. This fabric would serve as a soft cushion, providing a more comfortable user experience.

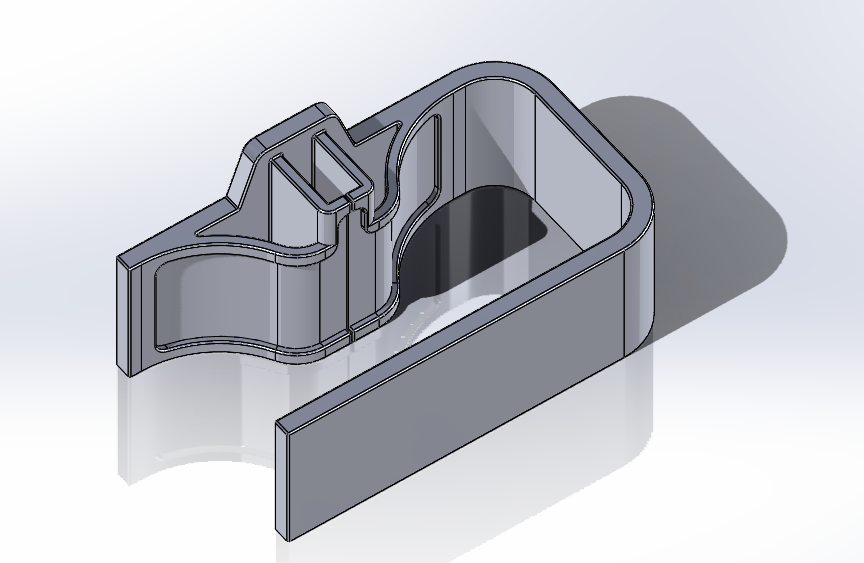

New design

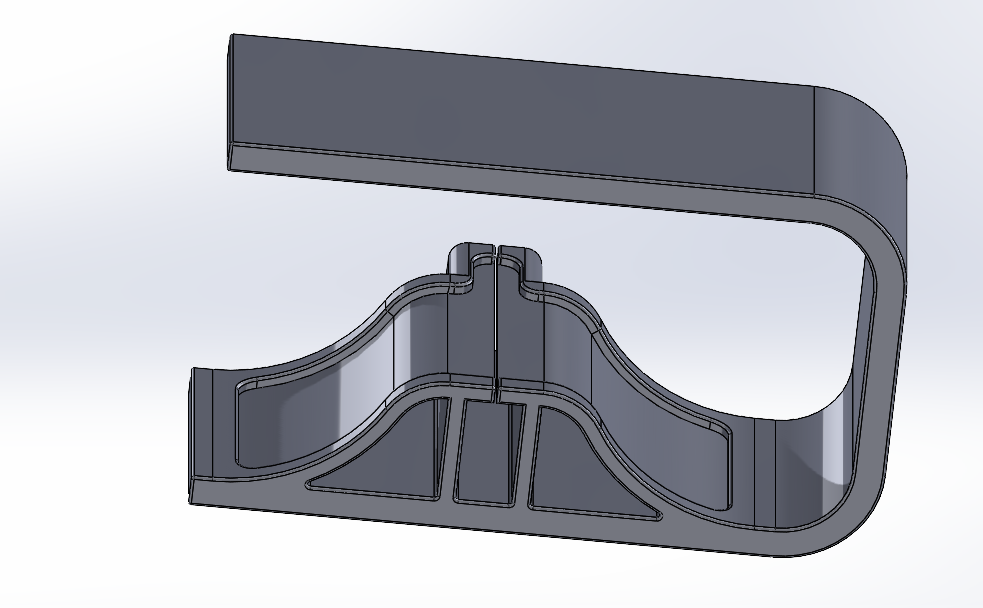

To implement this on the 3D model, we created a 1.5mm cavity in the areas where Diego's hand would be in contact with the uncomfortable feature, allowing the cushion to fit perfectly. This design adjustment ensures ease of attachment and suitability for industrial manufacturing.

Detail of the new redesign including the cavity to fit the fabric

As you can see, there are some holes next to where the knife grips, so as not to waste any material when printing. With the design refined and finalized, we prepared the model for 3D printing to create the new prototype, advancing our testing process.

Bruno

Bruno New design

New design

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.