In today's class we created the prototype bellow:

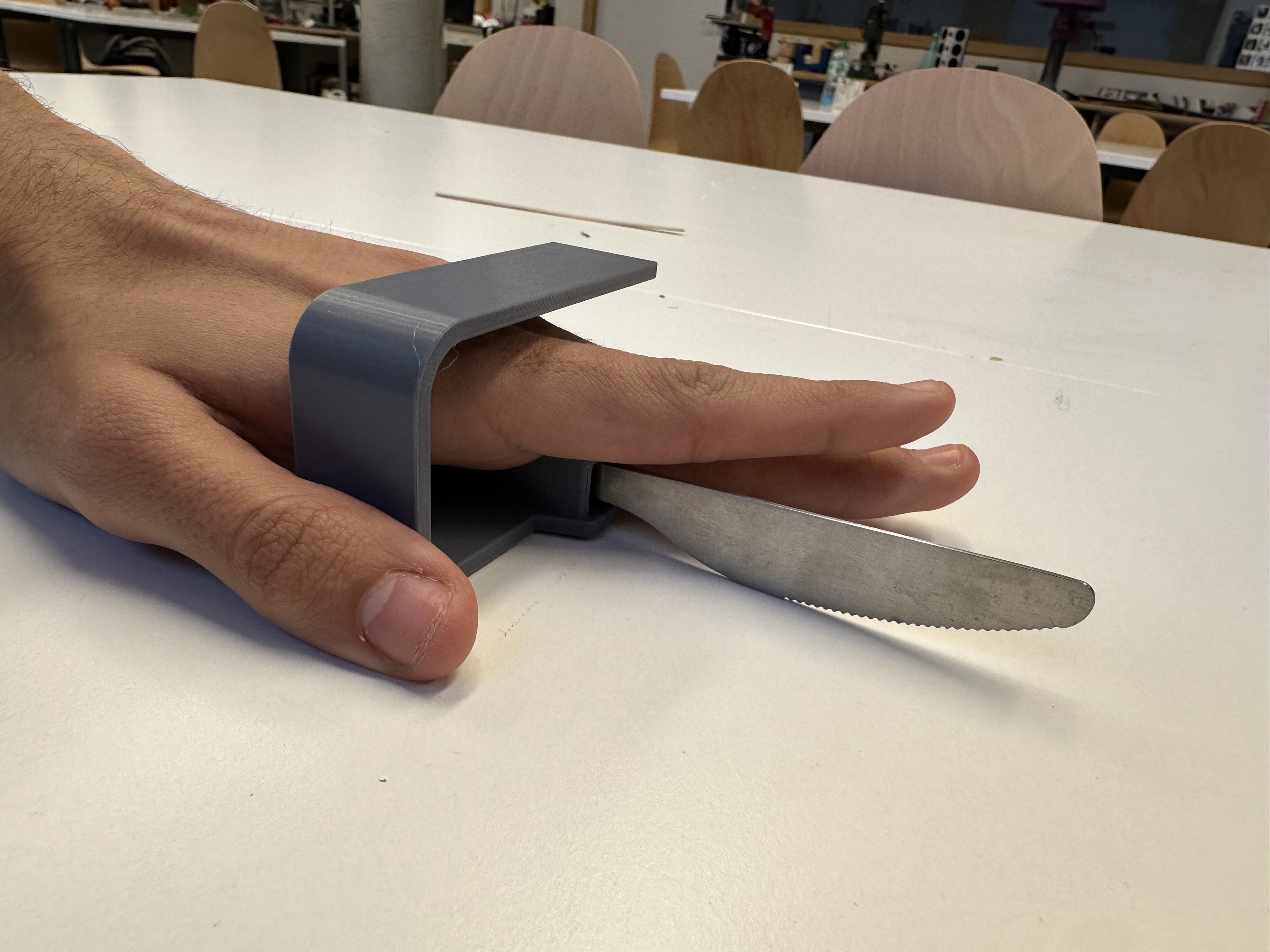

Testing the prototype in a hand to check the ergonomics

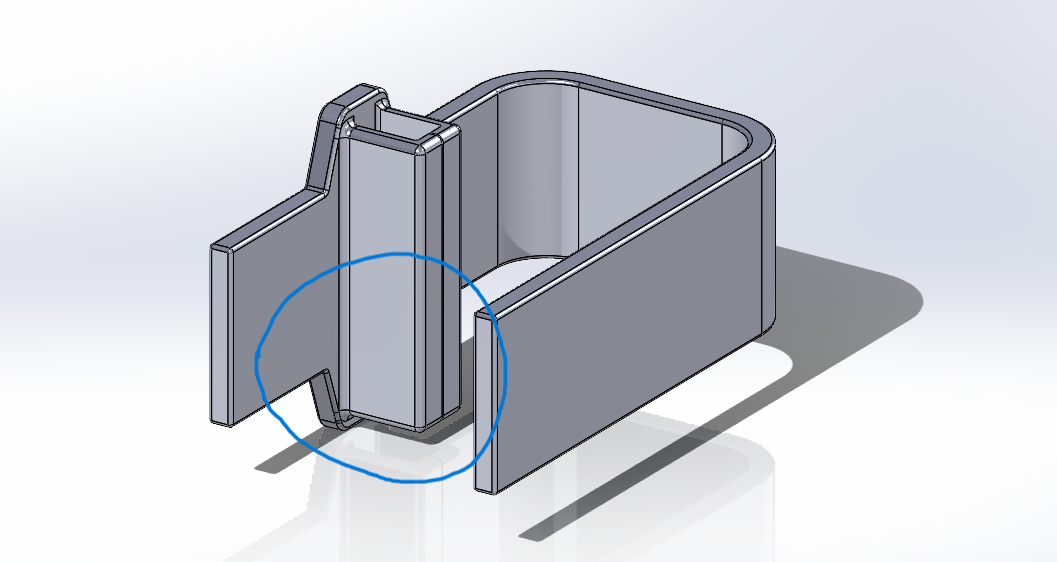

Using Solidworks, we develop a 3D model tailored to Diego's hand measurements. We meticulously optimized the thickness to ensure maximum comfort and minimized the weight; as for simplifying the printing process, we detected that it wasnt necessary to have this V shape mirrored in one of the sides, because with just one V shape the knife would totally be secured and locked in its placed. Also, getting rid of this part, will lead to reduce material and printing time.

V shape in both sides.

Additionally, we refined the edges to maintain sharpness while ensuring safety. As you can see in the images, this prototype enters the knife from a different axis so that the force of the hand and the plate counteract each other. Furthermore, we made a very little cut where the knife is placed so that it adapts to any knife handle, even if it is larger.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.