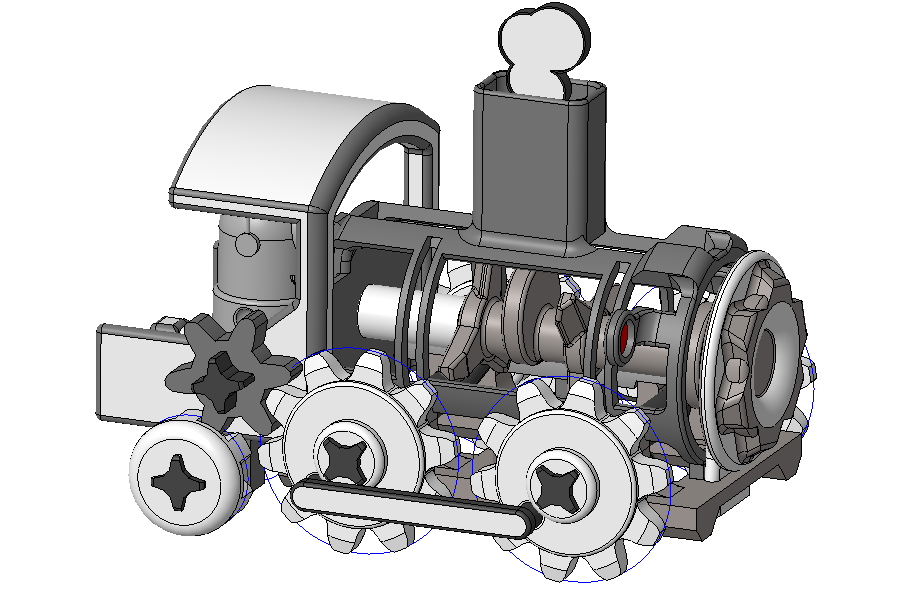

In today's class, we focused on finding a new solution that integrates gear mechanisms and as well cam followers, following our previous research and study into this type of message display. Our goal is to demonstrate movement and make it realistic, so by using gears and designing the cam followers of train we will begin our work. In this case, we will try to simulate the smoke effect a real train would have by integrating cam-followers not only here but as well in the minion located in the back of the train. To achieve this, we downloaded a train, ensuring this could be ready for printing. Following this, we proceeded to design the two cam-followers mentioned above and to the assembly of the train as a whole.

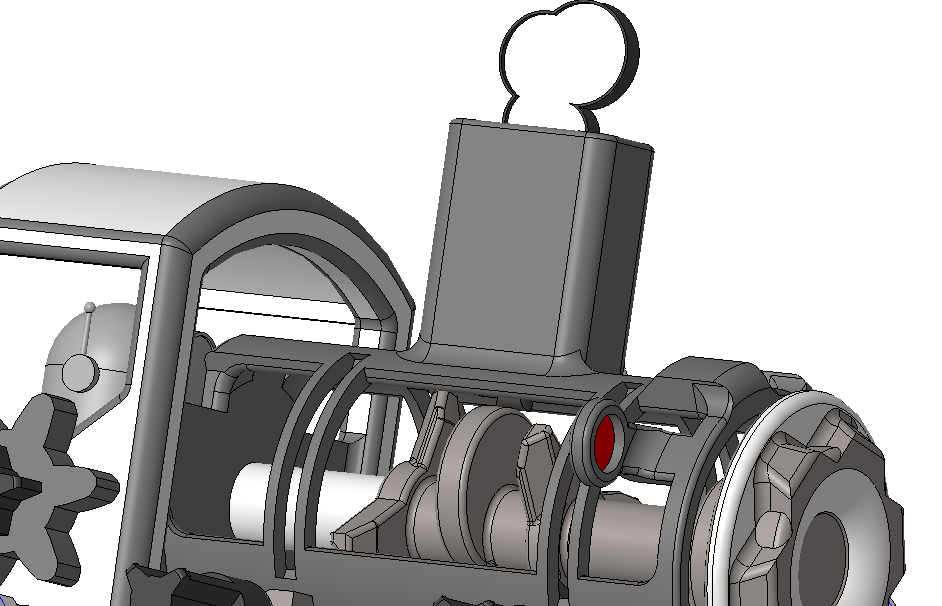

Detail of the smoke cam

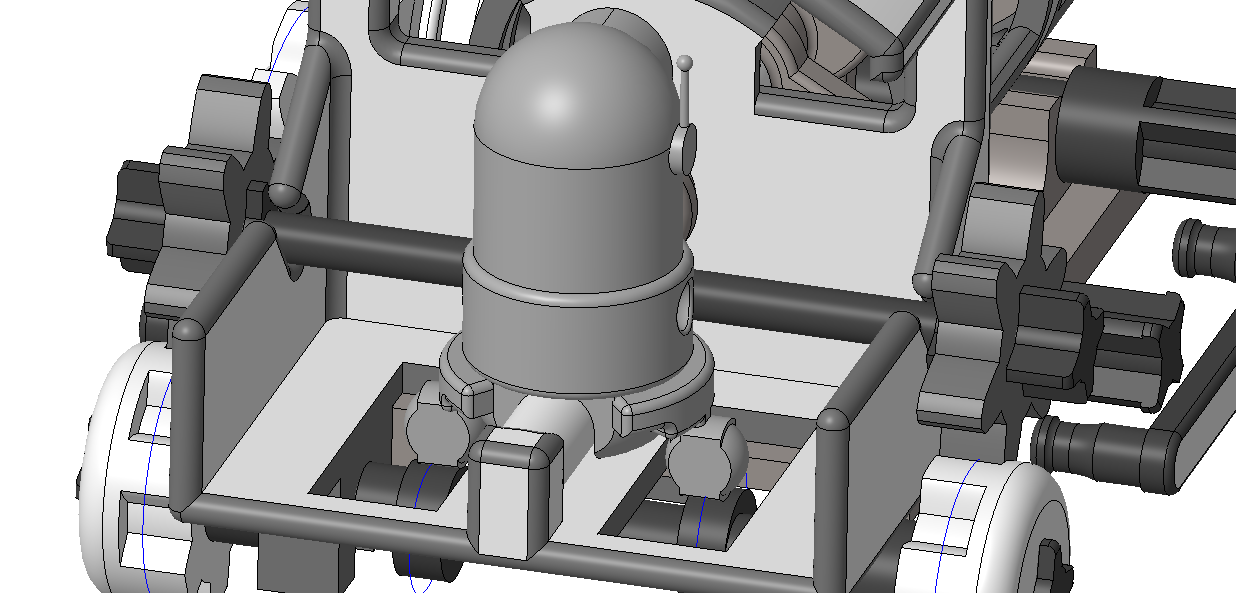

Detail of the minion cam

For assembling all parts together, we utilized the CREO 10 Parametric tool, which offers robust capabilities for assembling mechanical systems. This software allows us to visualize and simulate the movement of gears and cam followers in a virtual environment. By doing so, we can observe and refine the mechanical interactions before proceeding to the physical printing stage. This step is crucial as it ensures that all components will work seamlessly together once assembled.

Train assembly in CREO PTC

The ability to simulate motion on screen provides us with a valuable preview of the final product, enabling us to make necessary adjustments and corrections. This reduces the likelihood of errors and ensures that the printed parts will function as intended. By using CREO 10 Parametric, we can confidently design complex mechanisms and ensure their proper operation, enhancing the overall realism and functionality of our steam train project. From now on, we will embark on this new direction, preparing parts for printing and working towards creating a final functional prototype.

Bruno

Bruno

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.