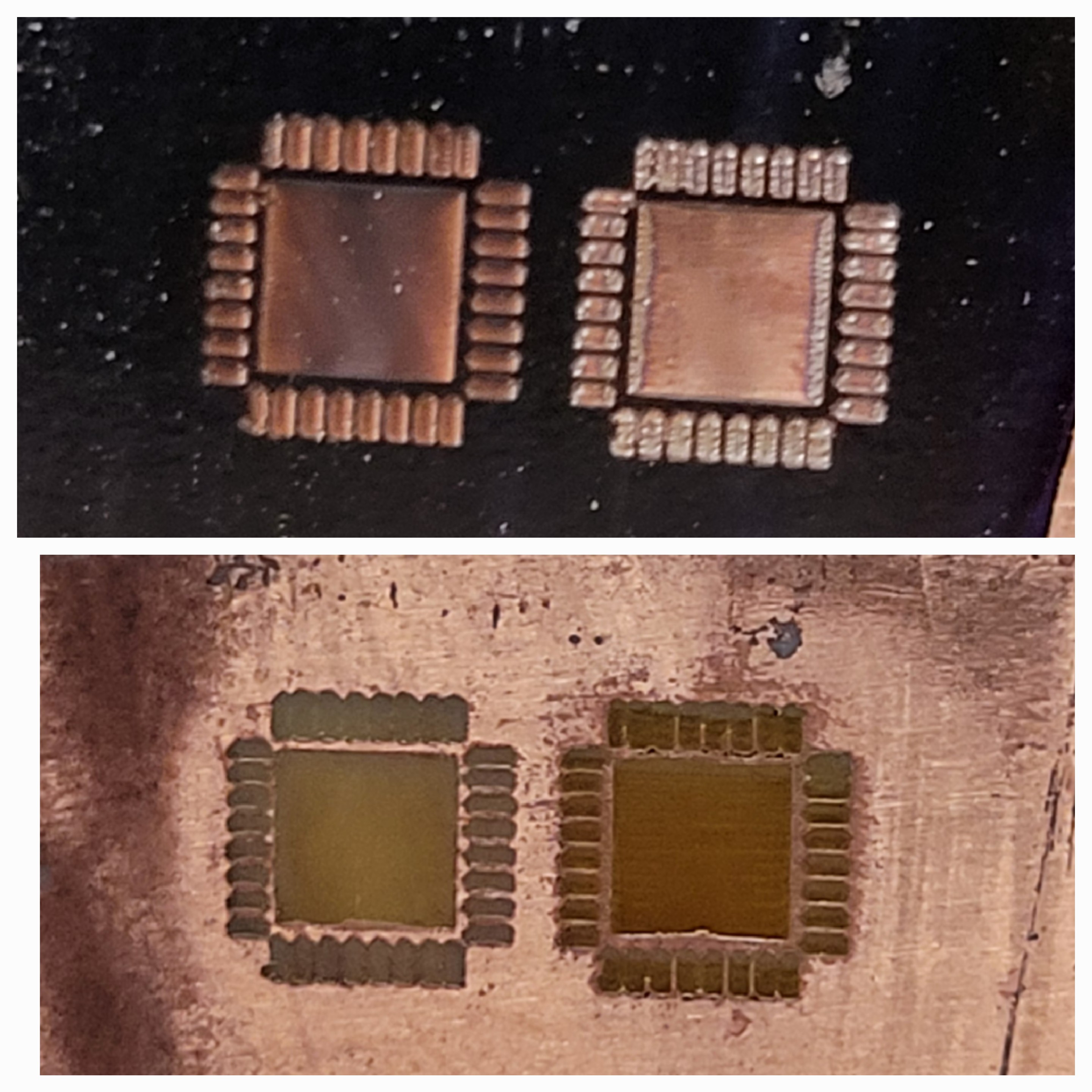

Although the results was good enough I had a feeling that it can be improved. I heard that some people use laser. So I've tried myself standard 0.5mm pitch

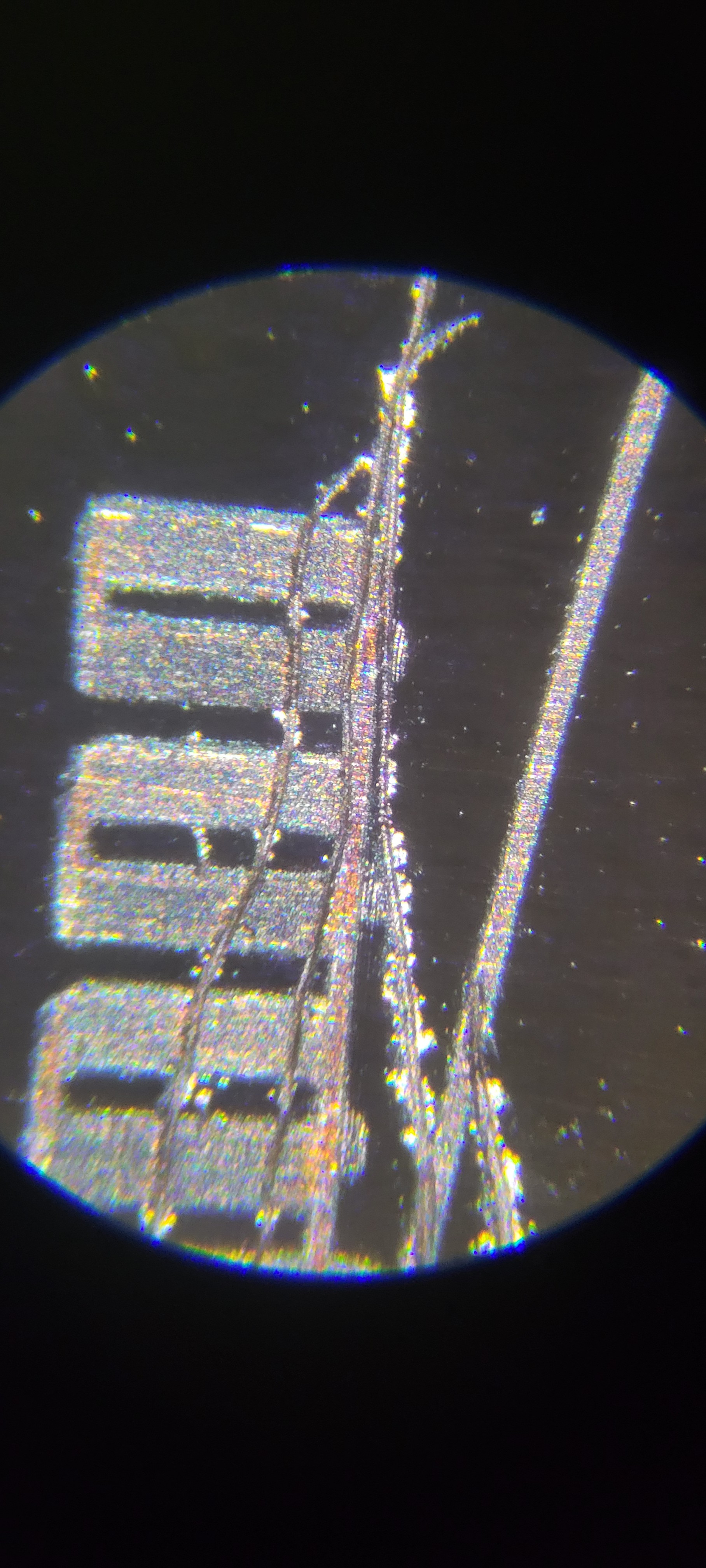

Let's look under the microscope

No broken bits no height map. I've tried to run laser at full power and see if it will etch the PCB but the fumes was terrible.

The good news you don't even need fancy laser.

By the way this is 80w laser with 0.08x0.08 point but it looks like they tricked me. It's not dense as it should be

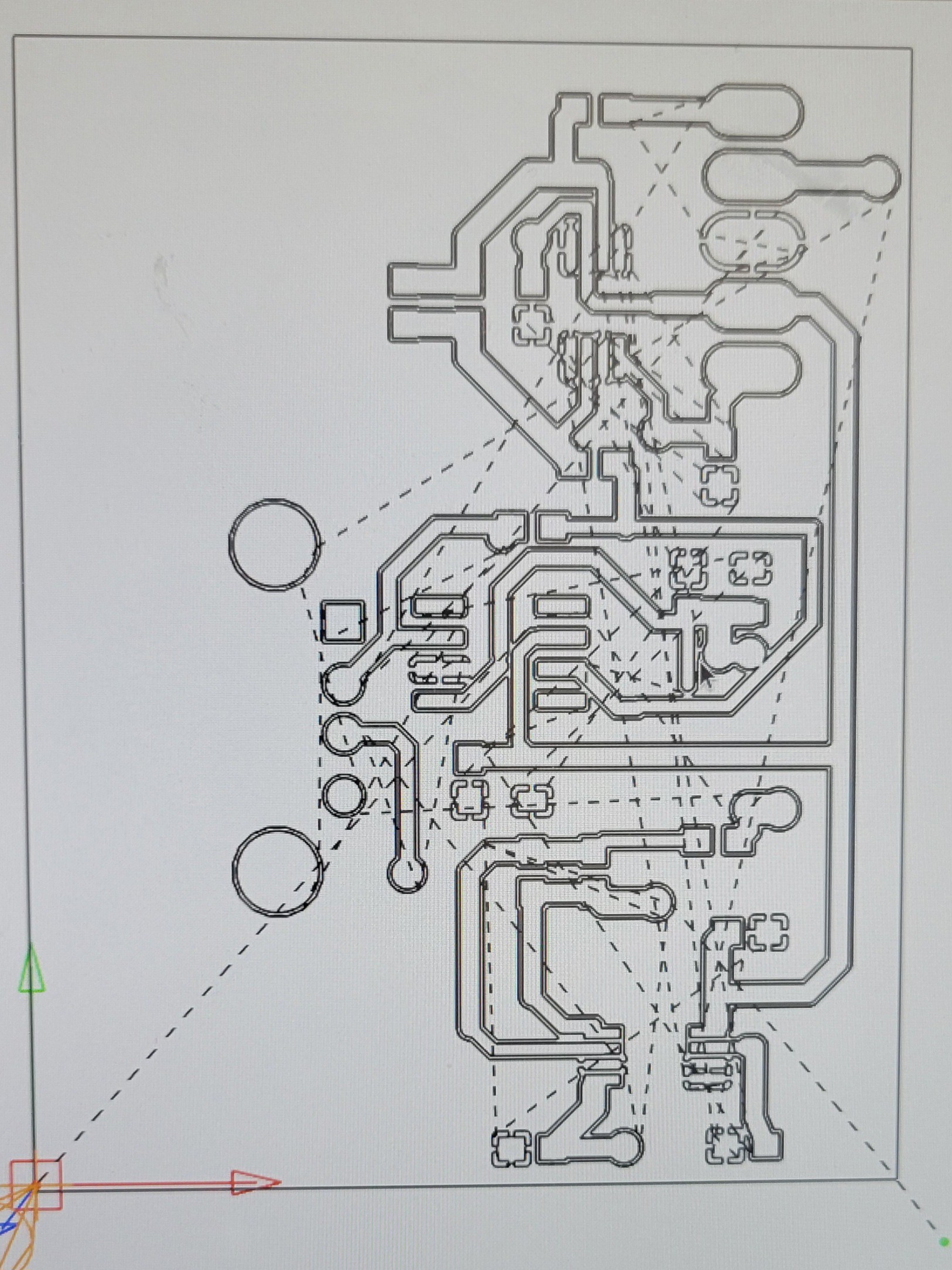

It took me some time to learn how to convert standard CNC Gcode to a laser one. In the end it was just changing Z up/down movement to laser off/on.

Synthesized Gcode for a tesf

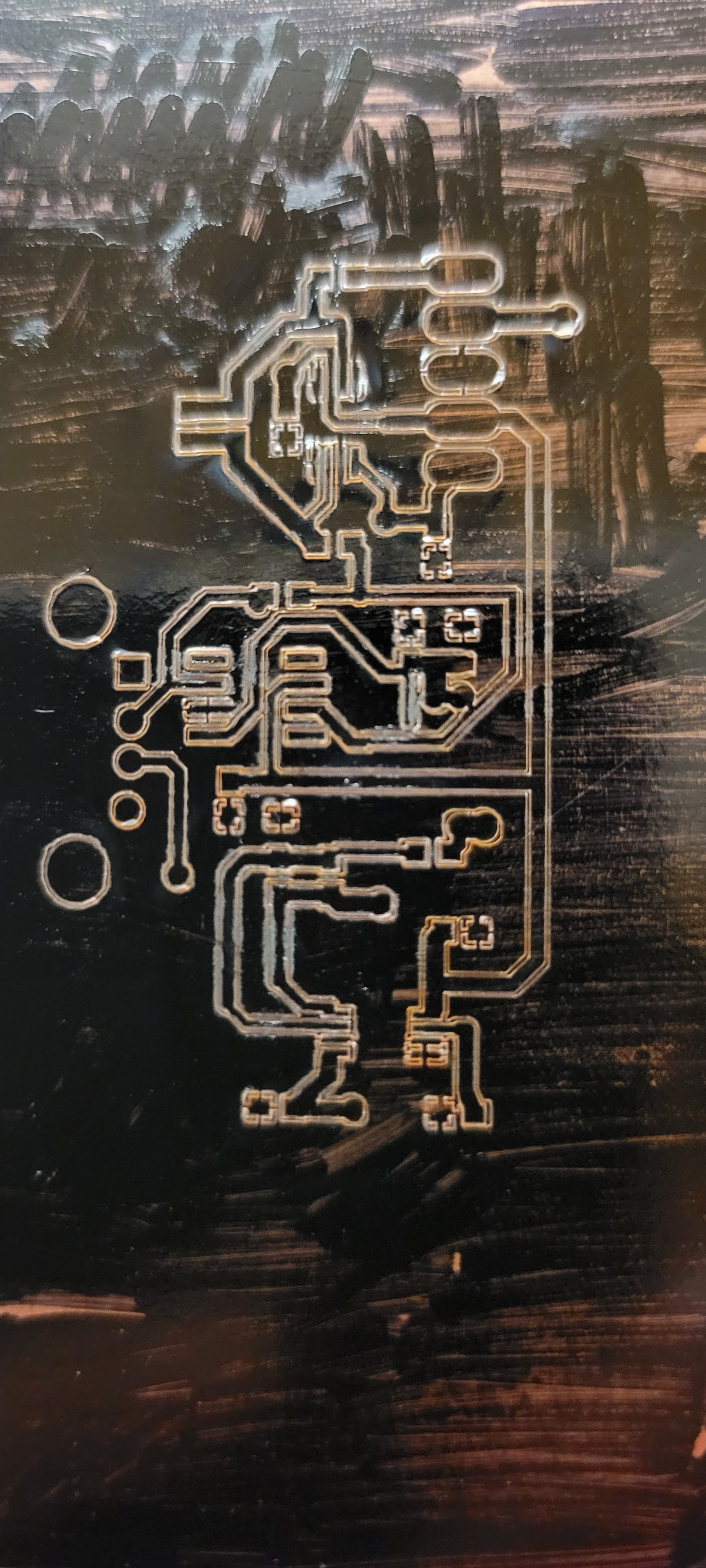

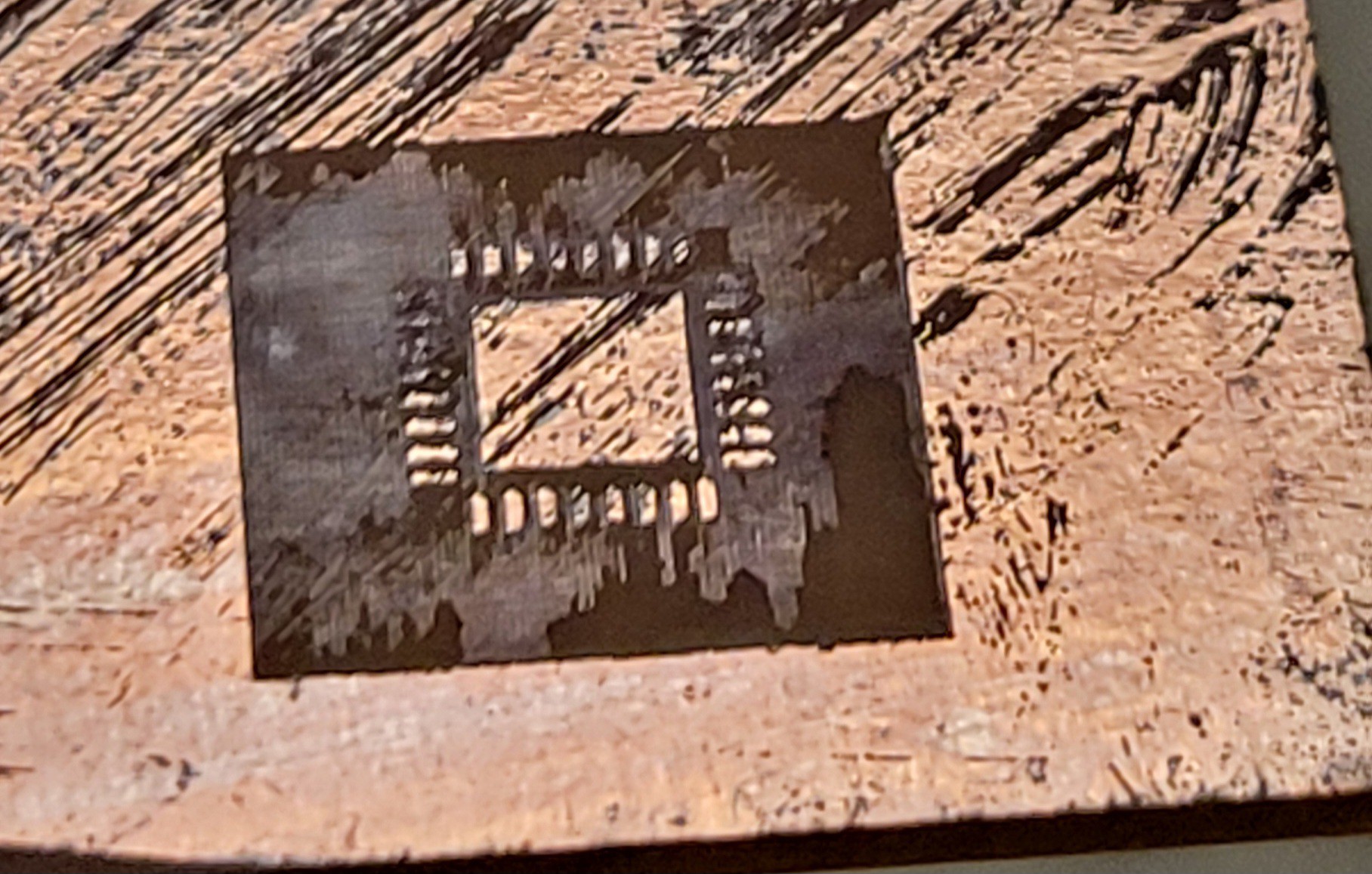

Now let's see the quality...

We got quality that hard to get with CNC even with 0.1mm bit.

It's my first attempt, no need for height map adjustment.

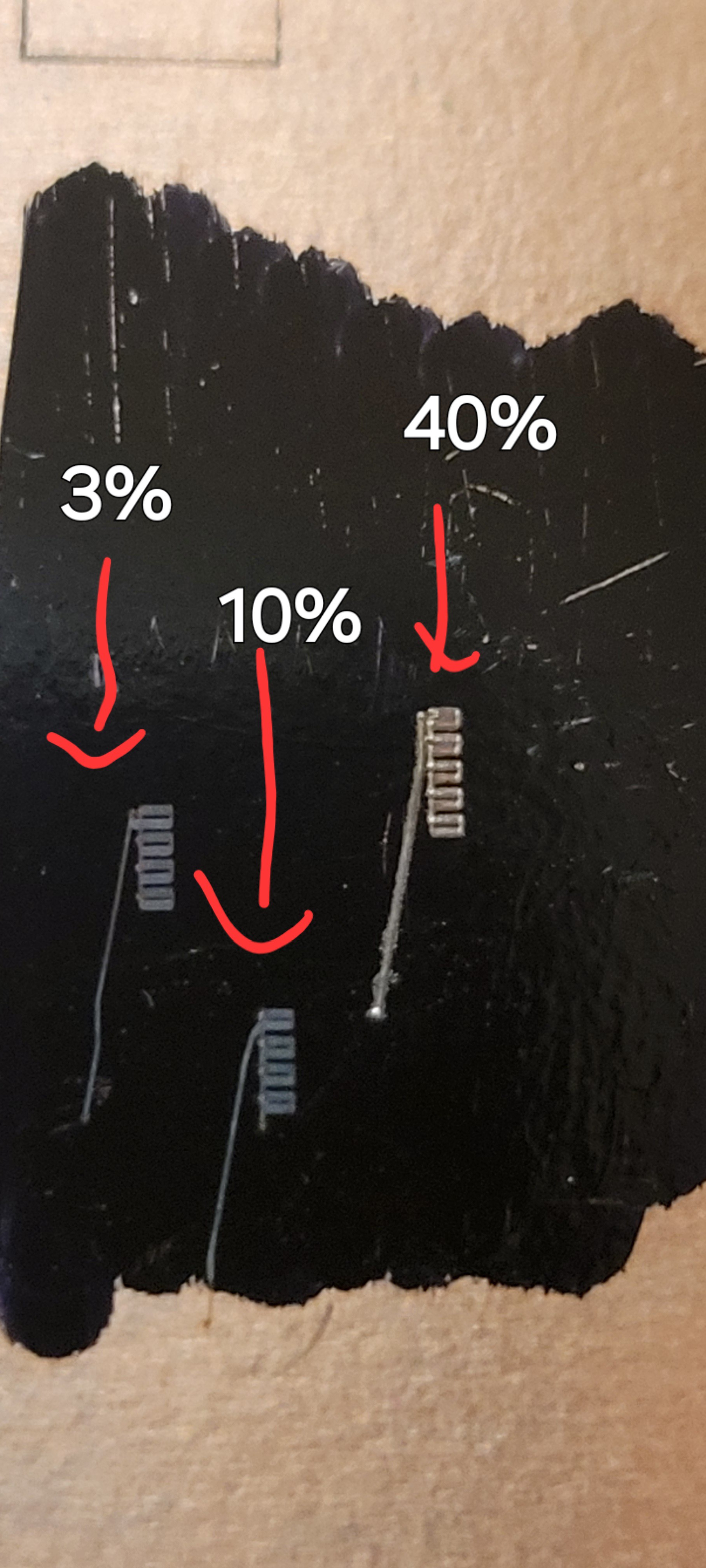

Tried different way, instead from Gcode that goes over the contours, use imageto create raster scan. The results are impressive also. (We use the smallest pitch possible of 0.5mm) Here 12.5% of 10watt power.

Also tried the negative image with 7.5% of 10watts laser.

This is very important since CNC method cannot take out much copper which is a problem when you want space between terminals.

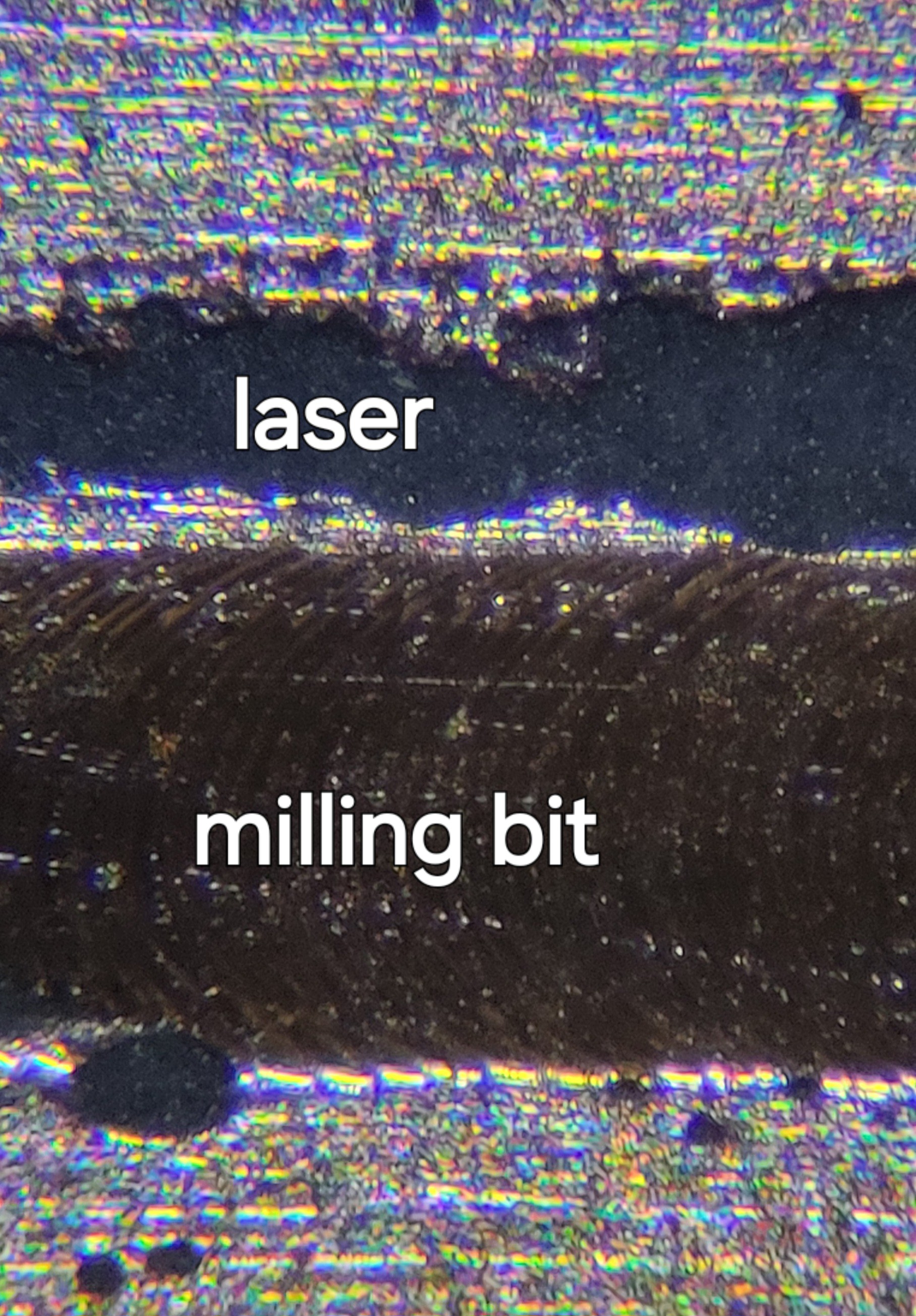

Ok, it took me some time to realize how to work with laser. I thought that more power means faster removing of copper. It turns out the opposite, if you use more than 12% of 5w (optical) the copper get some kind of oxidation. Later this layer cannot be removed in etching process.

So, power of 12-7.5% and speed of F75-50 gives orange color cut. And it takes time but eventually it removed. While high power of 25% stuck with this whitish layer which cannot be etched.

I've tried some lasers and although they advertise itself as 0.08x0.08mm spot size they are not. Laser tree LT-40-AA for 50$ (one of the cheapest) and it gave me nice square beam spot. [Actually it's strange 0.08x0.08mm beam spot is only for 80W-AA-PRO version, I think it's refactored PRO unit with electronics of 40W]

Important thing to note is removing laser traced copper takes much more time, but in the end it removed.

The problem is that marker get removed also after such long time. So other coating material should be used.

With all being said laser, even over etched, is much thiner lines than using bits.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.