This is THE solution (drums please) 200$ IR 1064nm laser. First it's spot size is 0.03 which is amazing (actually I should measure this). I want to make a note here, it's not fiver laser which costs a fortune. This is diode based 1W LASERTREE (and not I don't get any sponsorship from them)

Second and most important IR laser does not oxedize copper as does blue laser. Oxidation is a huge problem when you try to etch it. Well, it's just doesn't etch properly and leave not etched spots means it conducting where it should not be.

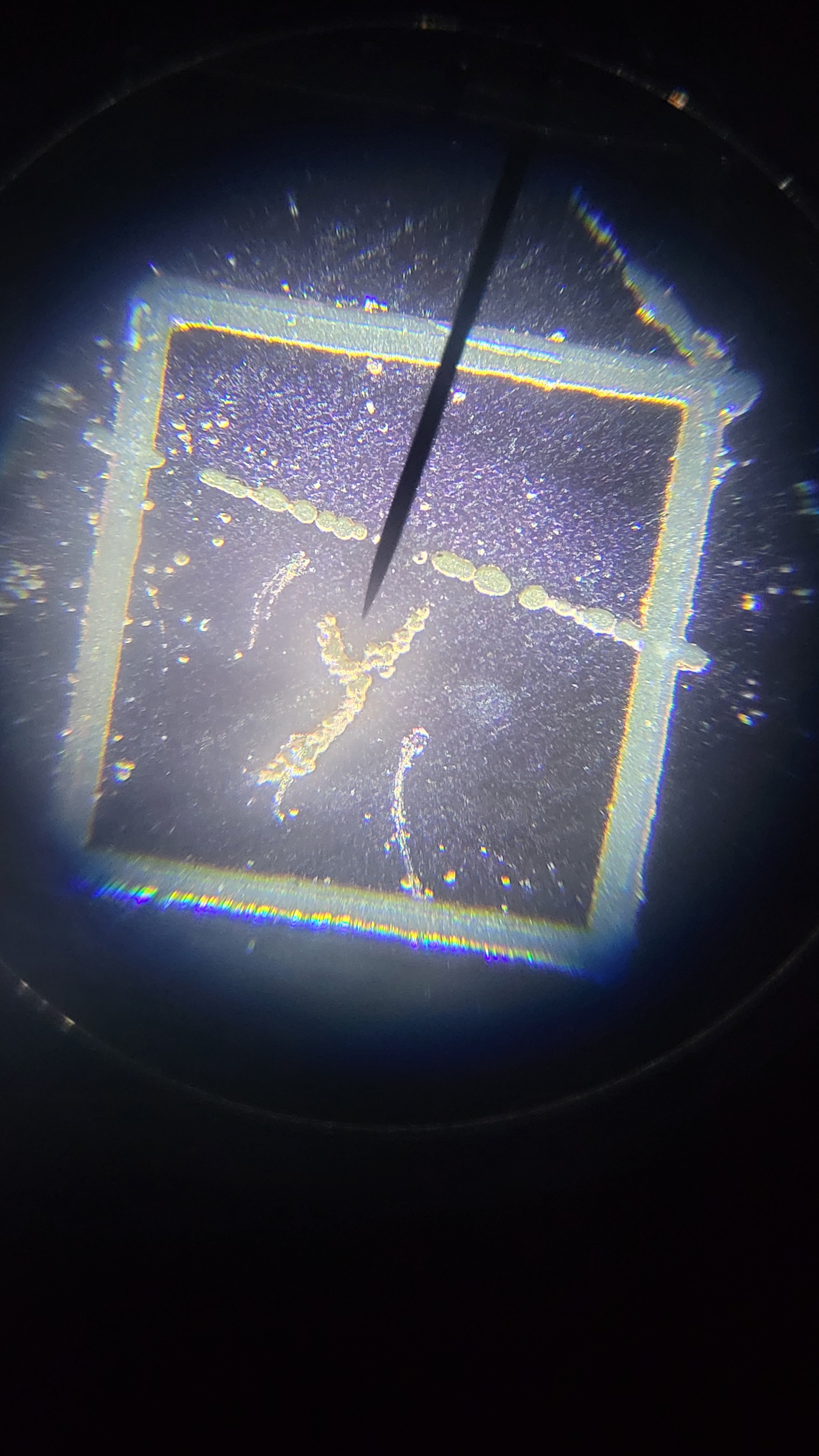

Here example of 3x3mm square using 1W IR laser and drop of ferric chloride under the microscope. (Ferric chloride is already washed away)

I would try different parameters but this project is definitely done!

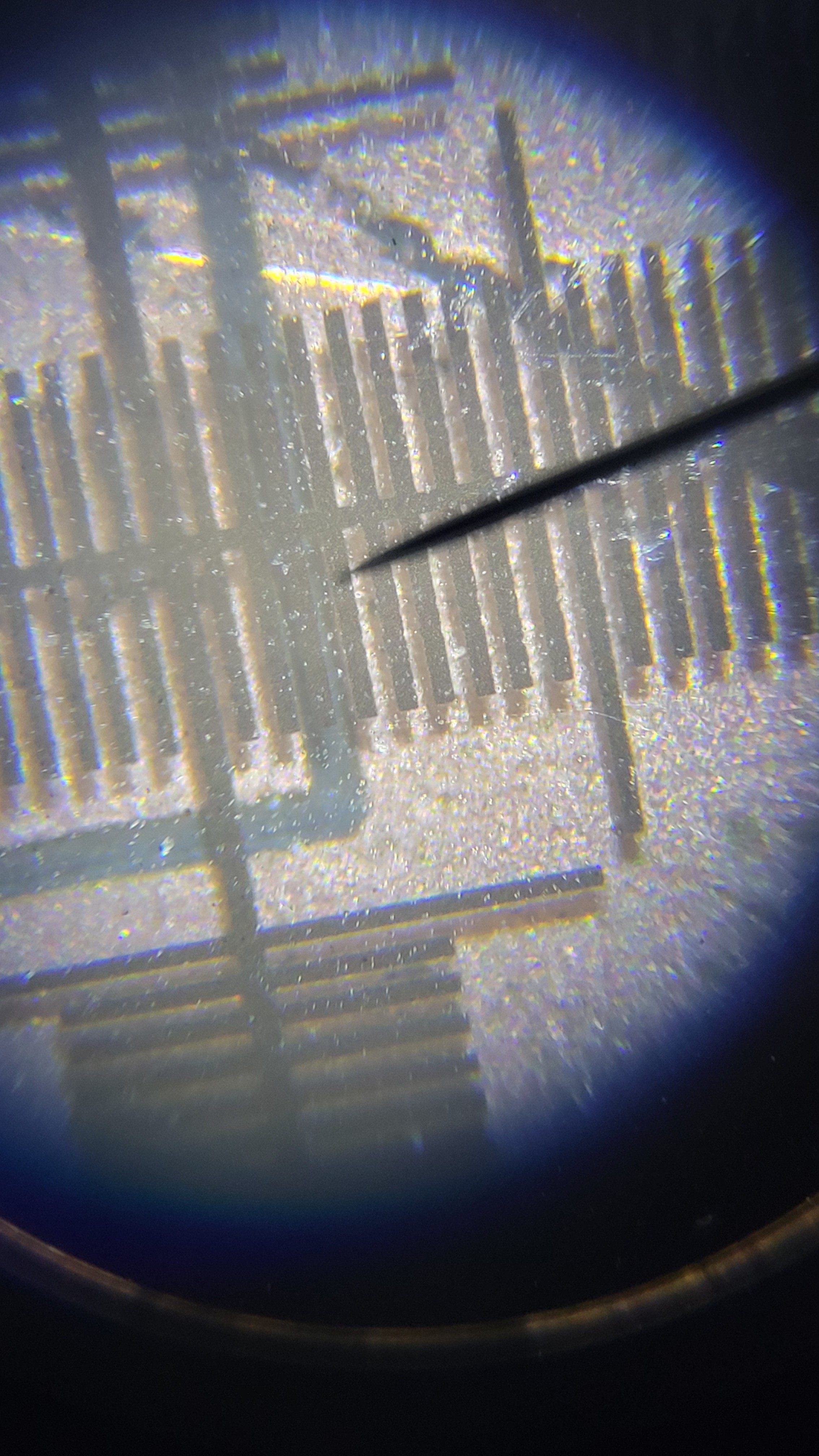

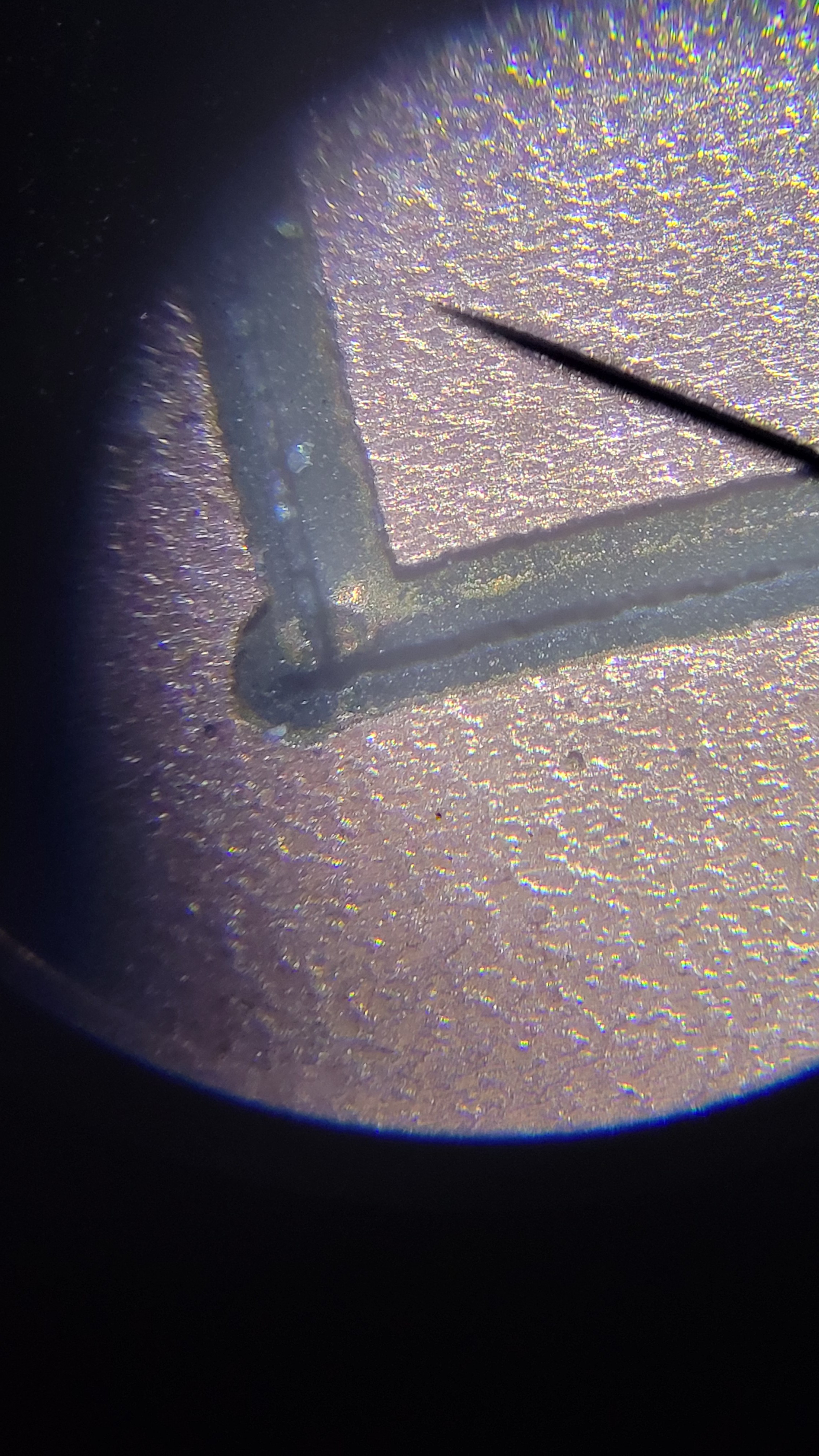

I thought it would be a good idea to measure the groove

It's less than 0.2mm which is very good for that price.

Also, 0.03 groove of laser beam can be seen

But id don't want to go there as the smell of cutting pcb board is terrible I prefer using CNC for that

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.