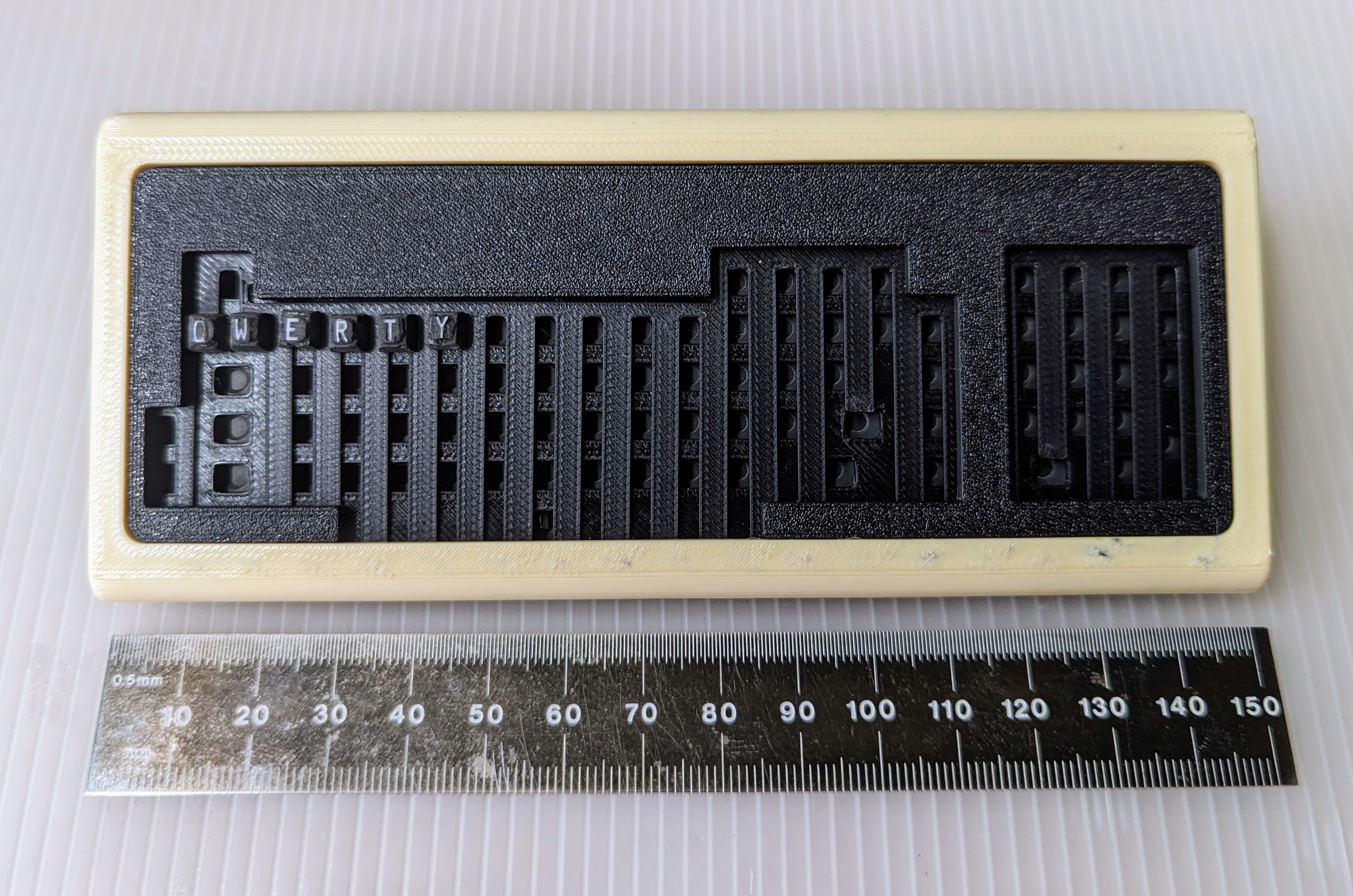

Ok! After quite a bit of iteration, trying different part shapes, materials, and layer stack-ups I have a working USB keyboard for the 1:3 scale VT100.

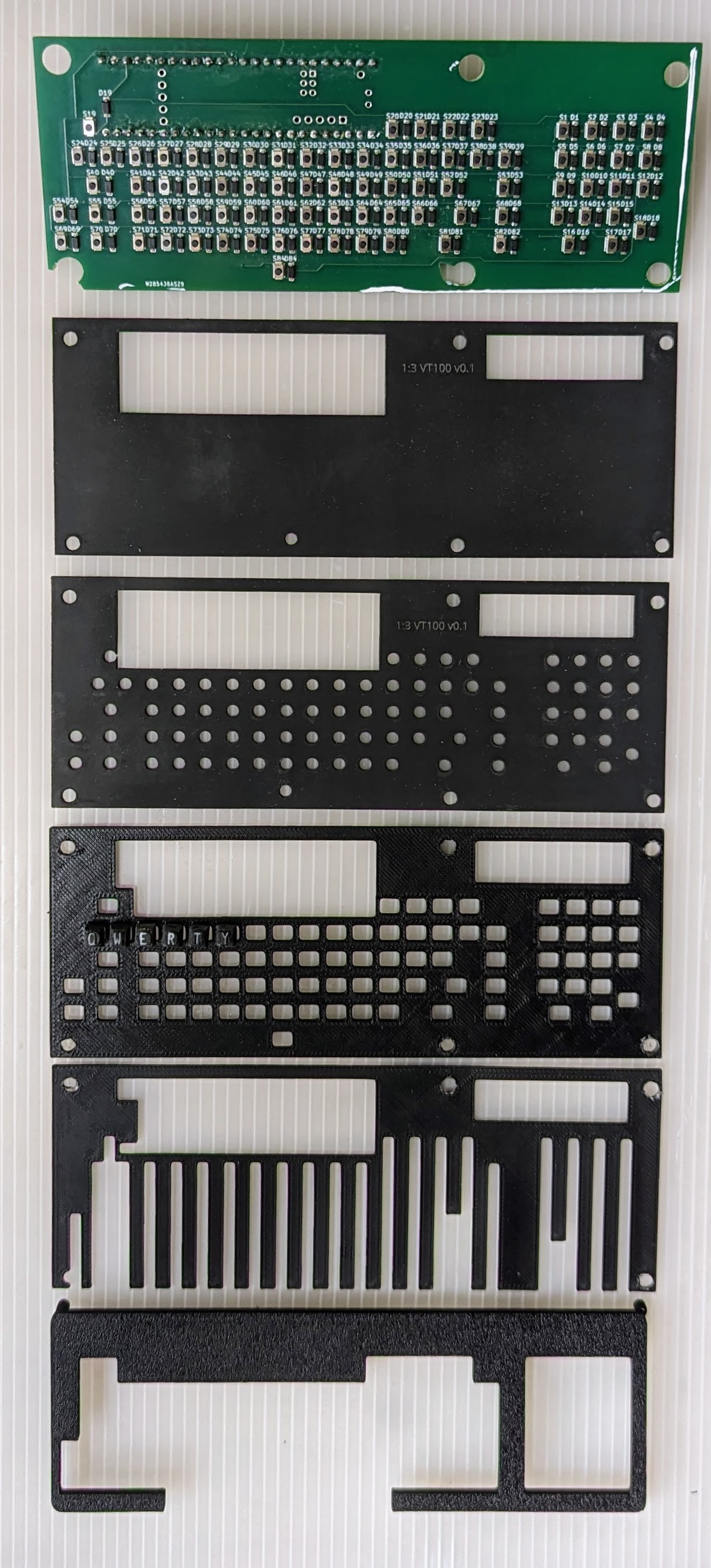

Here is the stack:

The layers in the photo:

- PCB on the bottom

- silicone rubber cushion sheet

- silicone rubber guide sheet

- switch shaft guide sheet

- switch lock-in sheet

- bezel on the top

The circuit boards contributed by the PCBWay board prototype team have been great, too. Each board has 200+ surface mount components so they would have taken forever to assemble if I had to do it by hand. Luckily, PCBWay has production engineers with a ton more experience than I do and millions of dollars in machinery at their command. So, I'm deeply grateful for Liam at PCBWay for reaching out to collaborate like this and for the rest of the team for making it easy.

As an aside, if you're a machine tool nerd like I am then check out this video they made showing the various machines involved with making PCBs. I've made PCBs at home using CNC mills, chemical etching, and even conductive ink so yeah, I'm deeply grateful for their help.

As you can see in the photo I've taken chunks out of the prototype board to move fasteners and I've drawn lines in white-out to show where the next revision should be cut. I'll also design a little daughter board to hold the four LEDs that will mimic the status lights on the original keyboards. KiCAD, here I come!

I'm using Teensie 4.1 boards as the MCU because it has enough GPIO for a full keyboard with numpad, lights, and if I can fit them in the case, a little haptic motor and audio clicker so that each keypress feels like it's a full sized mechanical switch. If you've used an Apple touchpad recently you've probably experienced a similar haptic trick as the most recent touchpads don't actually move, they just feel like they do because of a little motor jiggle.

In a future log I'll go into how I'm combining resin printing with polymer clay casting to make the keycaps and actuator shafts. In the meantime, I post behind the scenes photos and videos over on Mastodon: @trevorflowers@machines.social

Trevor Flowers

Trevor Flowers

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.