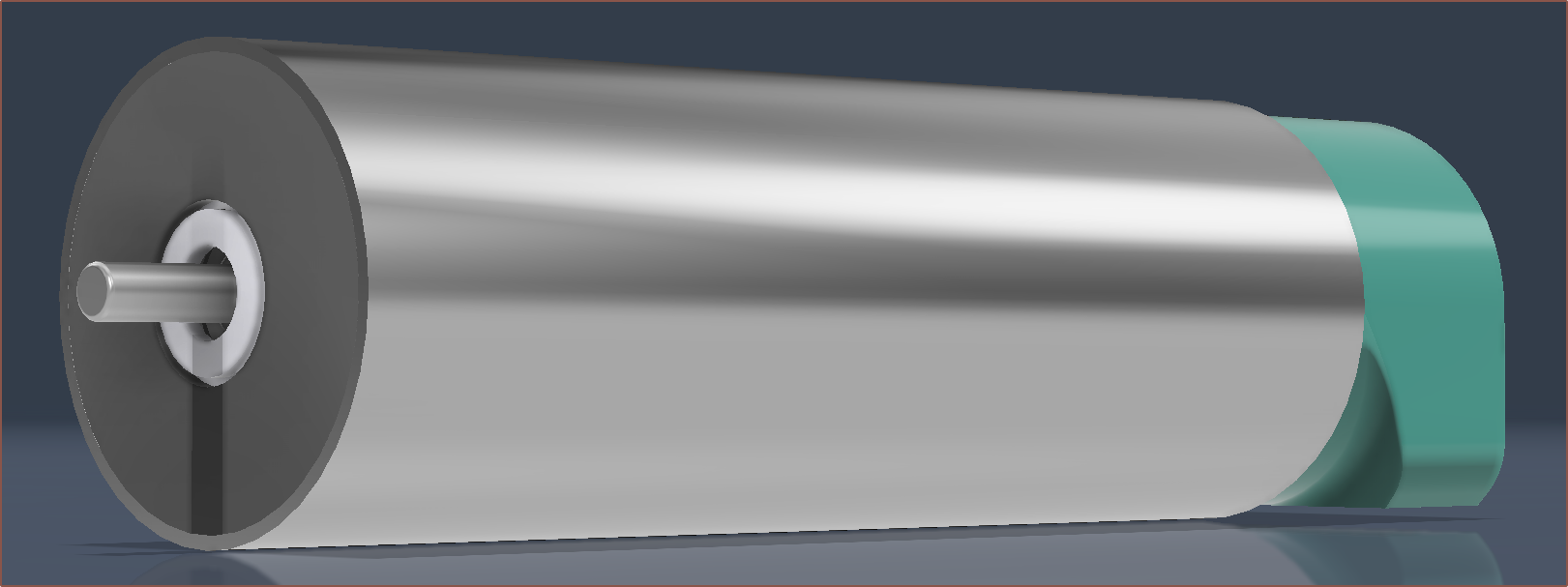

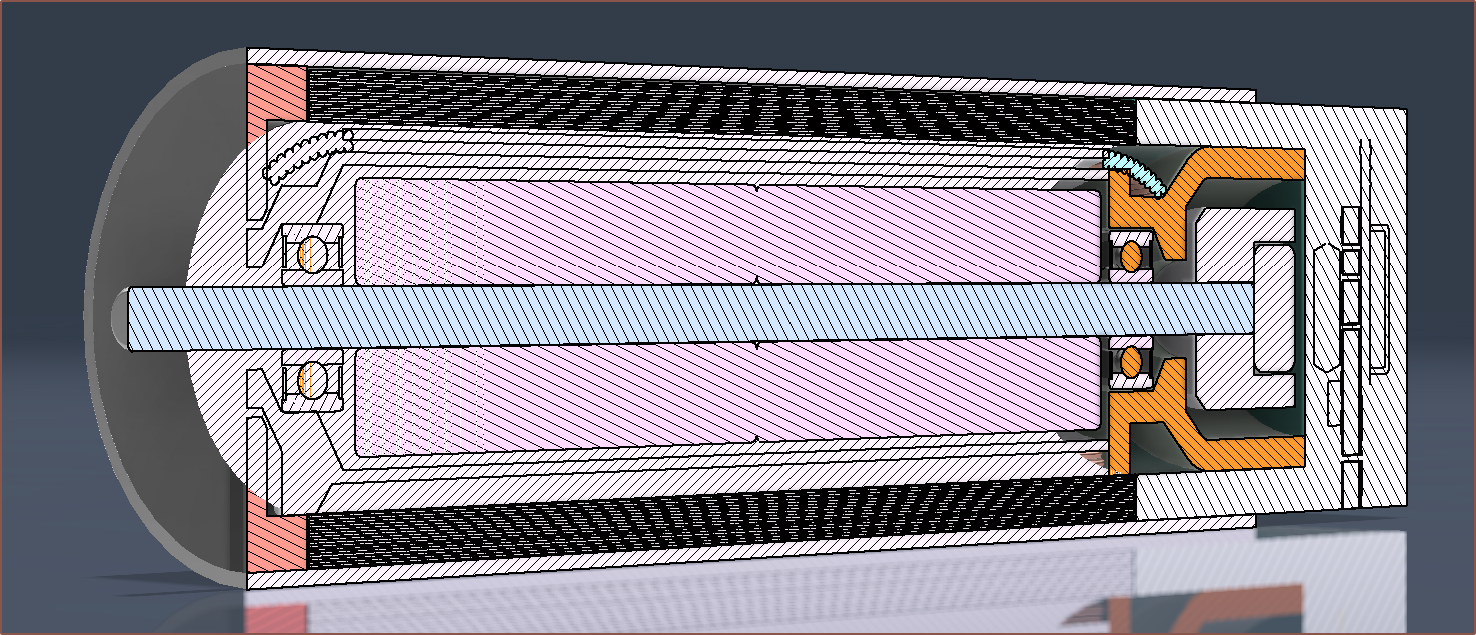

I must've been intoxicated with hopium if I thought I could get away with not having a stiffening tube over everything. The toroid, coils, and overmould are all flexible components around the magnet, yet finger force is applied directly ontop of the motor.

Conveniently, AliExpress has just the tube I need:

I've modelled in a 49.5mm tube so that I've got some cutting tolerance:

I've modelled in a 49.5mm tube so that I've got some cutting tolerance: I'd also like to avoid needing a semi-circle cutout for the silicone PCB assembly, but I don't have confidence I'd be able to get away with it. Oh, but I wouldn't be able to do that anyway or else I'd block the BT signal entirely.

I'd also like to avoid needing a semi-circle cutout for the silicone PCB assembly, but I don't have confidence I'd be able to get away with it. Oh, but I wouldn't be able to do that anyway or else I'd block the BT signal entirely. Anyway, the current strategy is friction fit, potentially heating up the tube to expand it slightly before assembly.

I'm really not a fan on how tight all the tolerances for this motor are becoming.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.