So, while asking multiple suppliers about custom toroid laminations, I learned some things:

- Prices are typically over the 15USD mark.

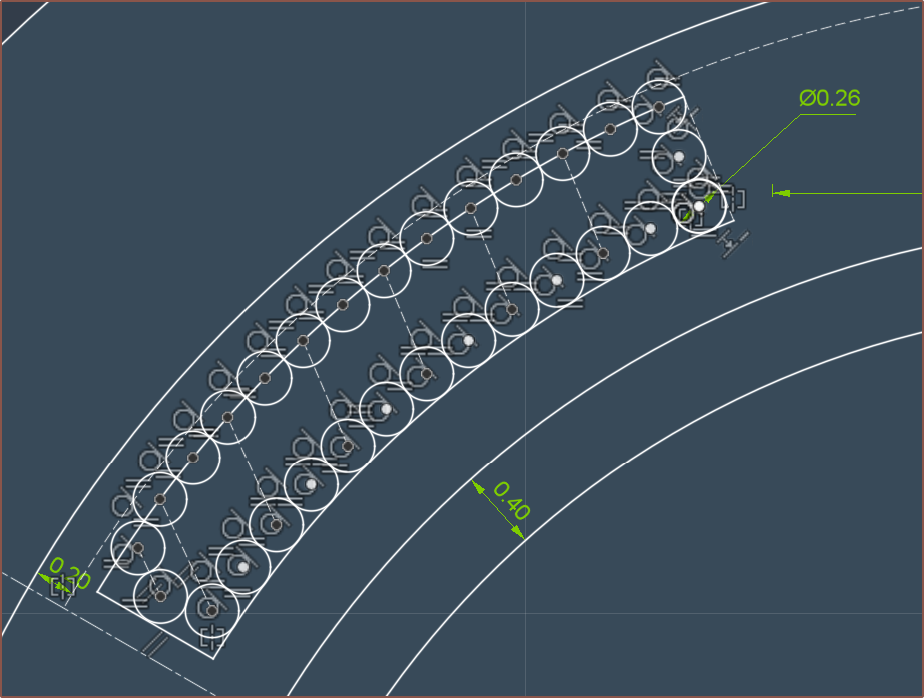

- Standard lamination thicknesses seem to be 0.2mm, 0.35mm and 0.5mm, with 0.35 being the most common and 0.2 allegedly costing more.

- One supplier had a list of standard sizes, such as:

- OD = 15, ID = 10.8

- OD = 16, ID = 12.4

- OD = 19, ID = 14

- These were all with 0.2mm laminations. Unfortunately, 16mm is the one that's out of stock.

- 15mm was sounding good because they could supply a 30mm and 15mm length to total to 45mm (and was asking if I could just have 3x 15mm) when I finally got the simulation set up and discovered that power consumption spiked from 120mW to 400mW+ (for a 42mm rotor) just because of that 1mm shrink.

- I think the 30mm length already exists and the 15mm length doesn't.

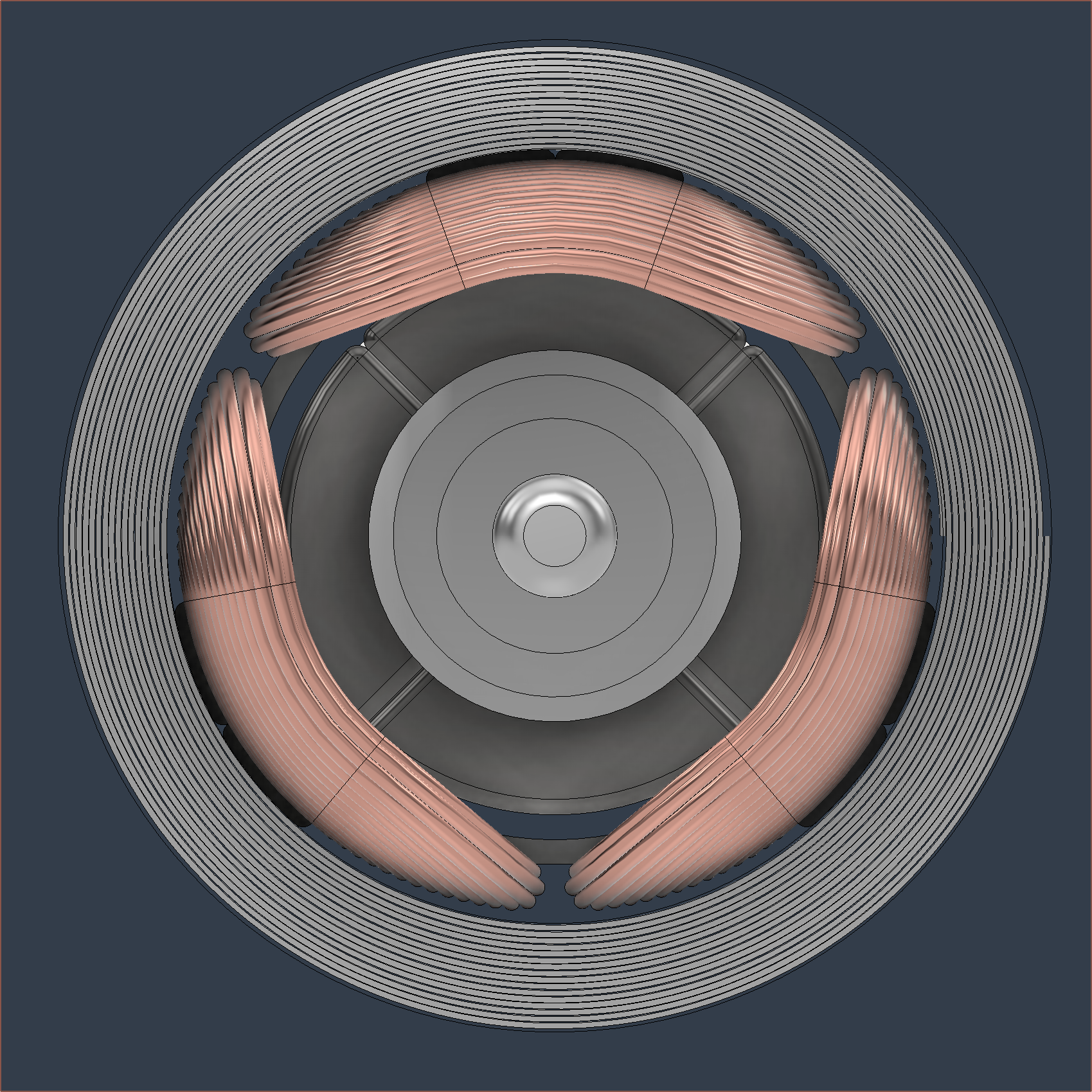

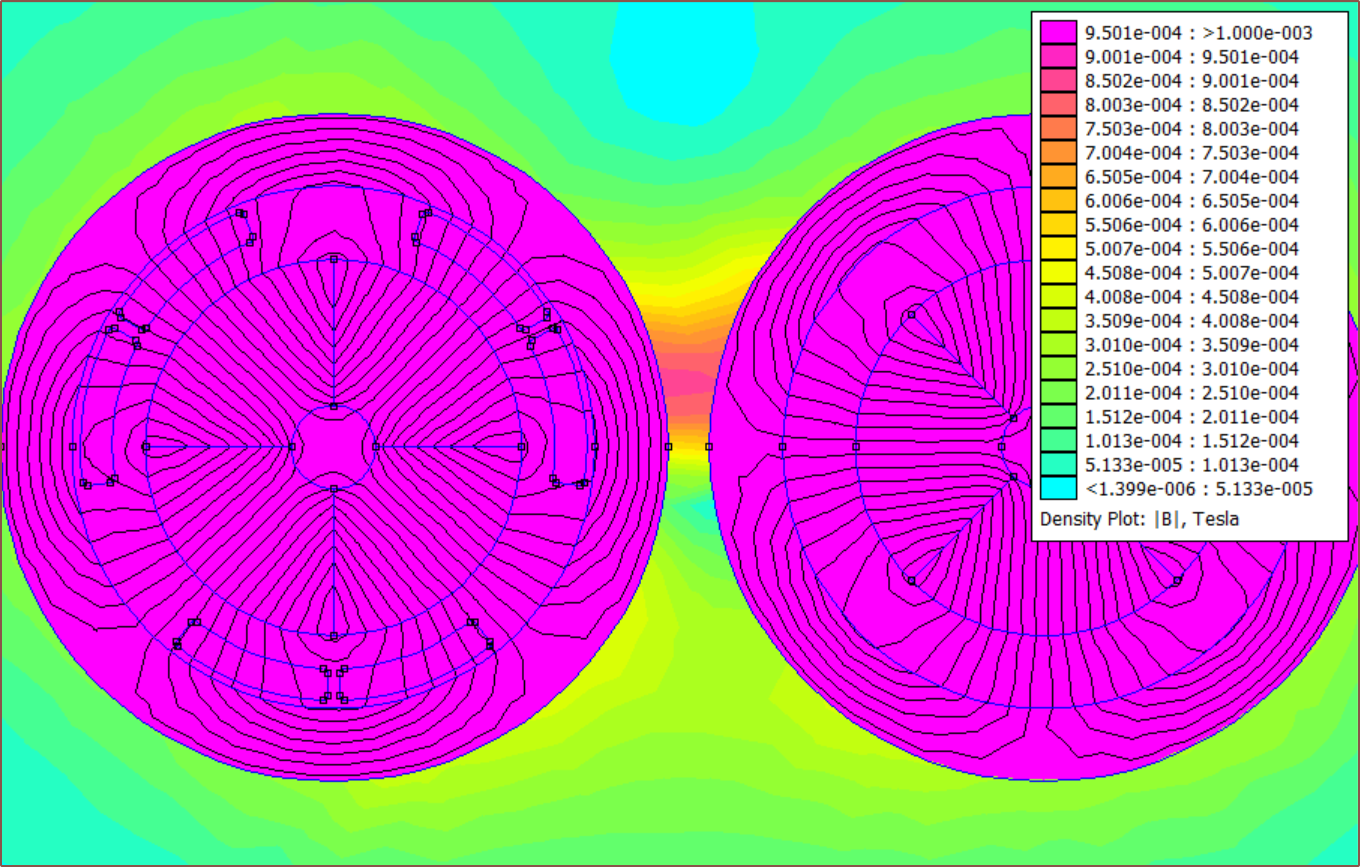

- I decided to try out what would happen if I were to go the other way, and the flux is barely contained at an ID = 12.5 and leaks out if ID = 13.5.

- An ID of 12.5 allows for a 9mm rotor.

- Below is a simulation using yoke material M-22, where purpie is anything over 10 gauss:

I have more confidence that my simulation is set up correctly if there actually is a standard size that's only 0.1mm smaller on the ID.

- The green insulation costs more because a mould needs to be created.

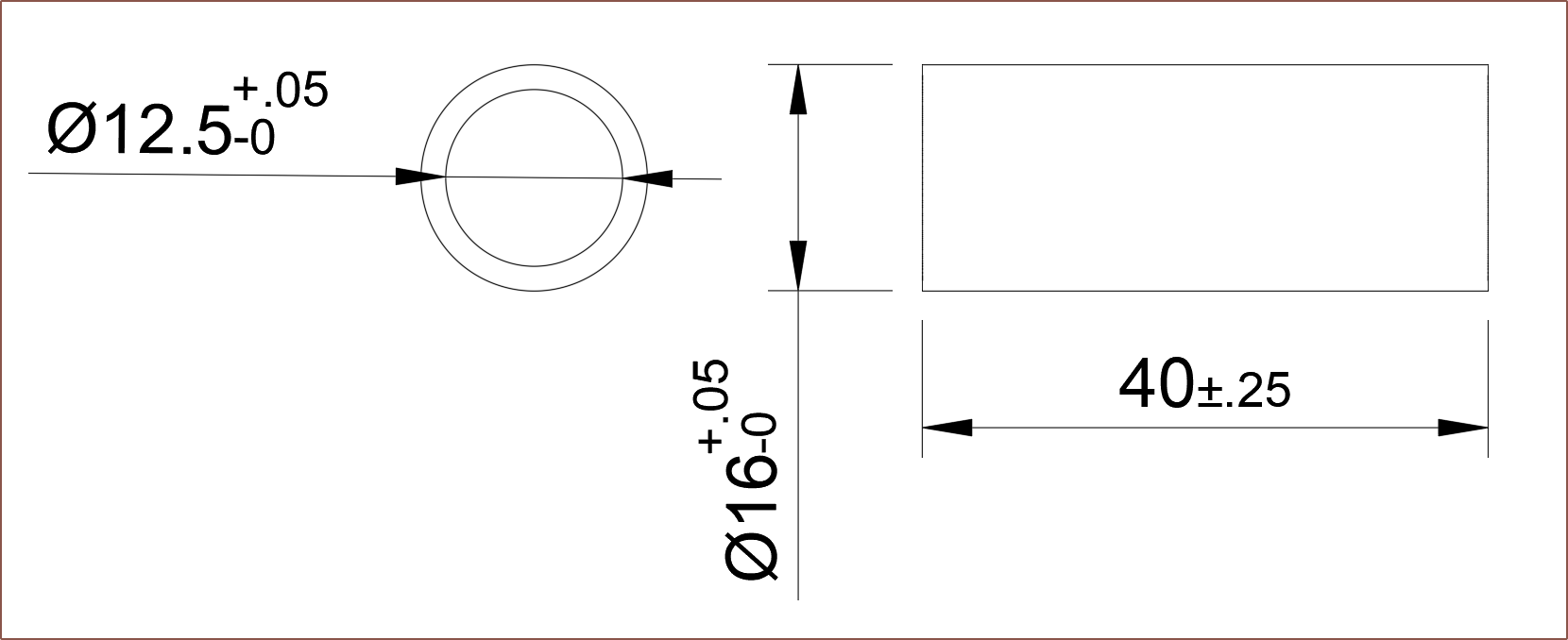

- I got some tolerancing information:

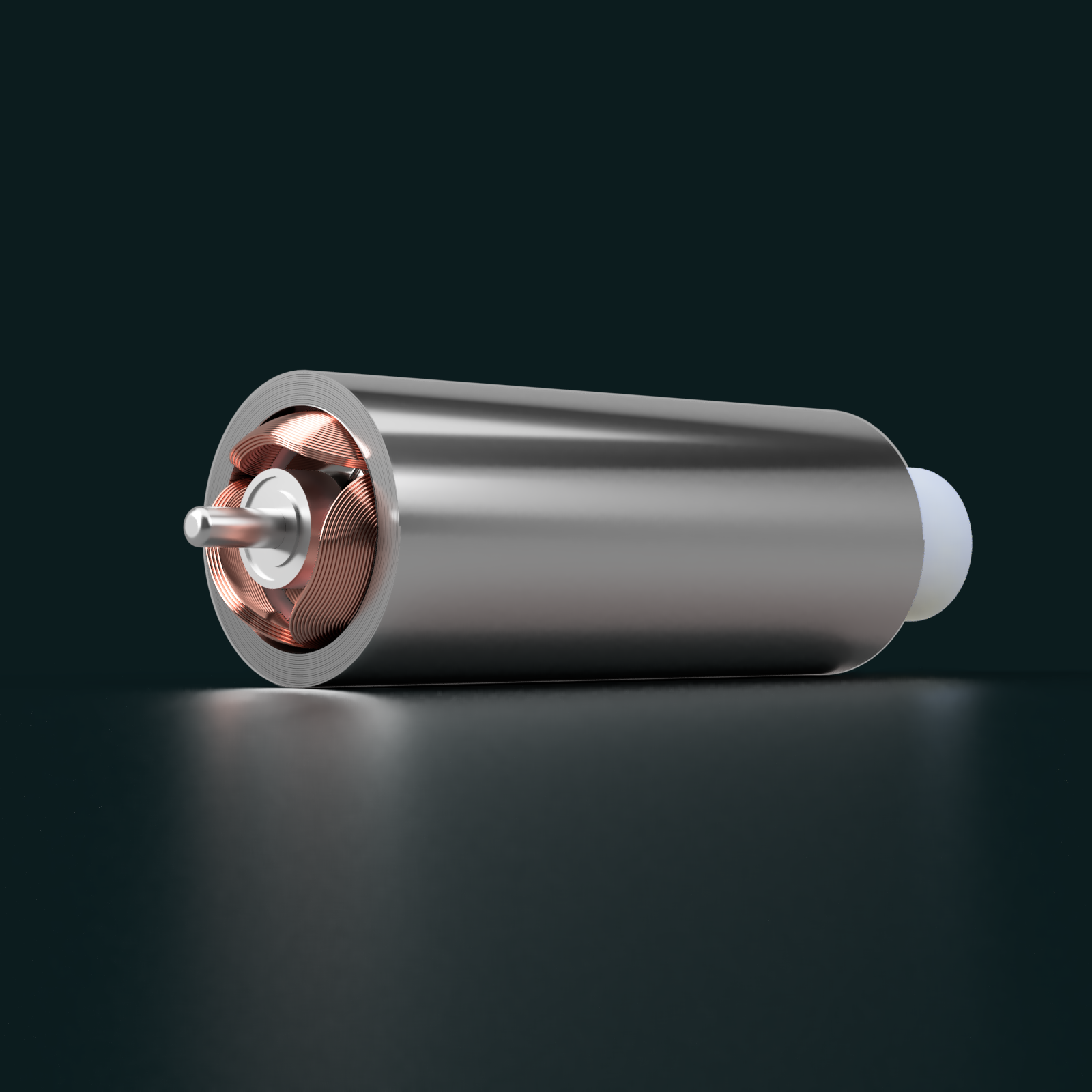

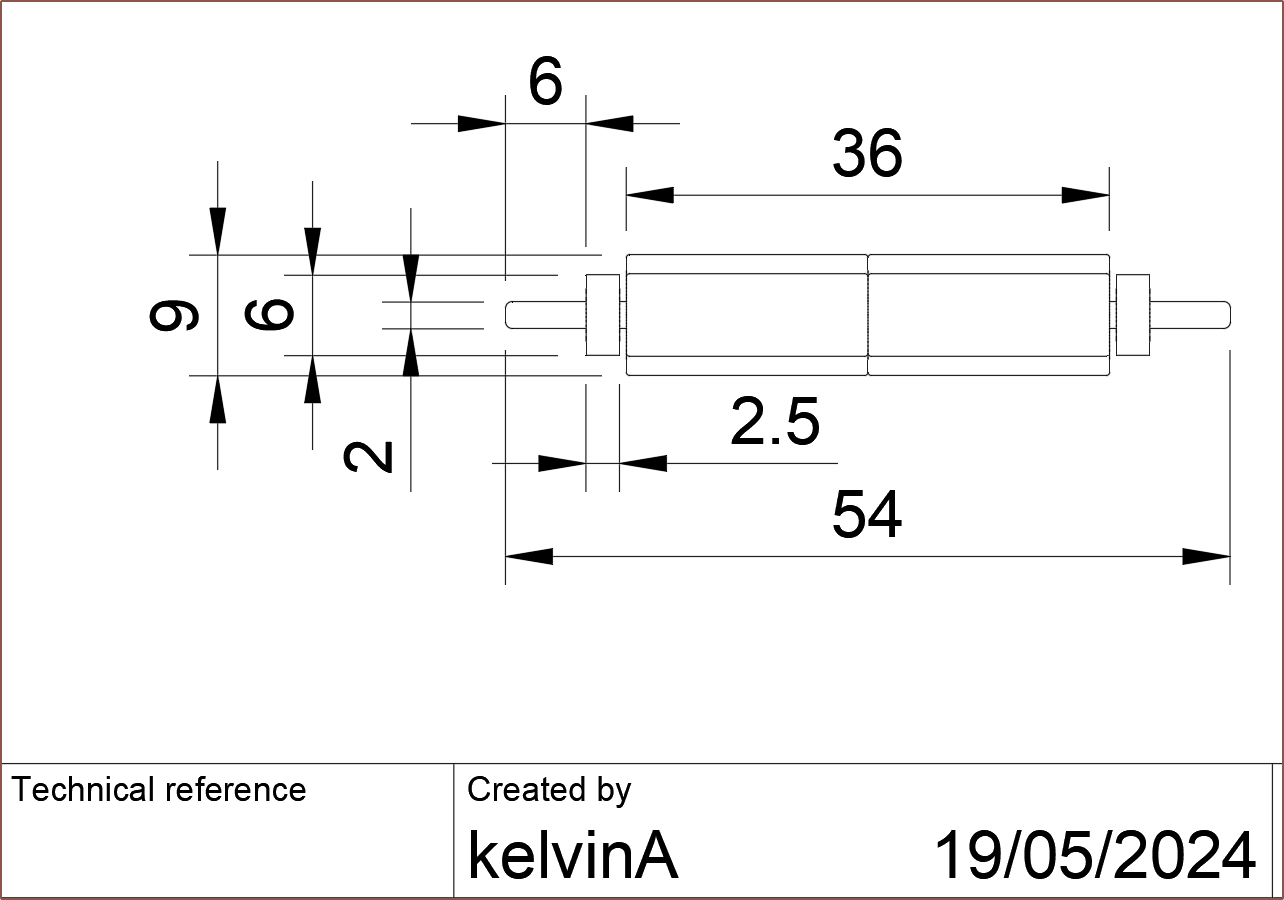

The stator is shorter because the expected PCBA thickness is expected to be 4.95mm. Additionally, I added an extra 4mm to the belt length of Tetrinsic that I've now removed. All in all, this means that the rotor has to decrease from 42mm to 36-37mm.

Due to the larger rotor, the power consumption is still about 120mW.

- Since I'm looking for a toroid, there is also the tape method for making the lamination.

The raw tape material (e.g. the fancy named Supermalloy) ia kind of expensive on AliExpress (such that it's much cheaper to just order the completed toroid from the supplier I found than coil at home).

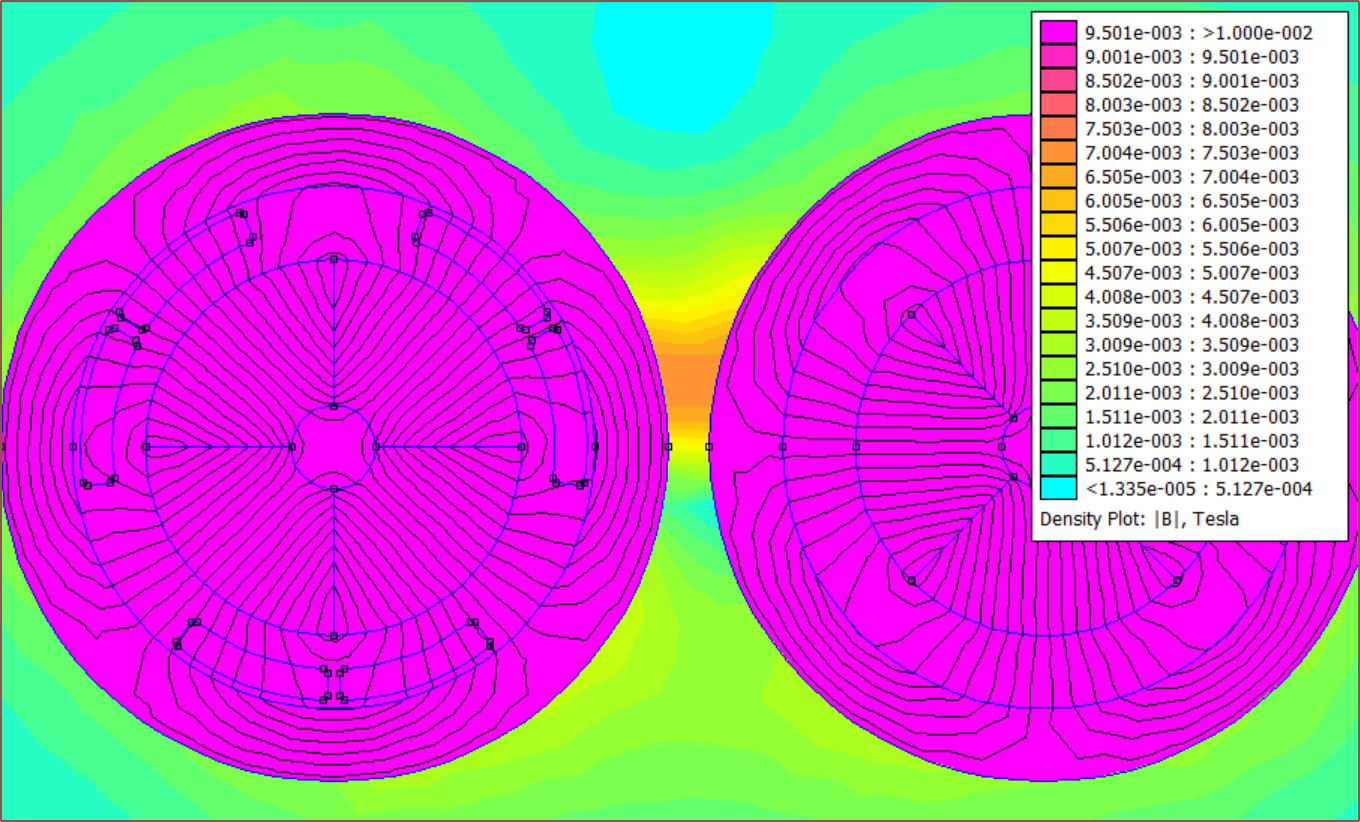

I looked though the materials in the FEMM materials library and was able to find Stainless Steel 430 where a 400mm x 1m foil is on AliExpress for £21. I'm hoping that I could get a 40mm x 10m for the same price. Below is a simulation with it, and it seems to contain the flux slightly better than M-22.

Each SS-430 yoke could potentially cost only £1.50, as the coil length is 0.707m and 14 lengths could be cut from a 10m roll.

Conclusions

So far, the lowest quote I've gotten is 8USD/ea.

I might want to consider simulating the eddy current losses with just a pure iron tube; since this is a low-speed application, they might not be too bad. At the same time though, it doesn't seem that such a tube exists; I just keep getting different kinds of steel in search results.

The foil coil method would give me the most versatility, and could potentially be used in the larger #Situation SeriouS [gd0098] motorised button without having to once again ask suppliers on Alibaba (unless I need a different length) and probably spend loads on shipping mostly air. Additionally, the foil coil could be directly wrapped around the stator unlike a traditional lamination yoke.

In other news, if I try and compute the expected torque constant to convert the BLDC made in the paper to the current design, I'm about 1/4 off:

Expected → 75mN.m [paper torque constant] x (9 / 11.5) ^2 [rotor size difference] x (37 / 25) [rotor length difference] x (75 / 130) [coil turns difference] = 39.22mN.m Simulation = 29.64mN.m [SS-430 yoke] = 29.78mN.m [M-22 yoke] Difference = 24.4% [SS-430 yoke]

[May 19]

The seller of the SS430 has a 10m listing for 40mm wide which is currently £40 (a little less than 2x the 400mm x 1m). Additionally, it's much more likely that I'd only get 13 completed yokes out of a 10m length. Thus, the expected price is £3.69/ea delivered after VAT, which is still less than the cheapest option I've come across on Alibaba (£4.39 pre-VAT pre-shipping from this supplier). Additionally, I'd have the freedom to experiment; perhaps when attempting to manufacture, I find out that 12.3mm or 12.4mm is better than 12.5mm ID.

For this to work, I'm assuming that the tiny but physical separation between turns will be enough to minimise eddy currents, as discovered in this DIY transformer core video.

Additionally, to make sure that there was enough exposed motor shaft, I've slightly decreased the rotor length and increased the shaft length.

The power consumption is theoretically 122mW and the Kv at 346 with 0.18mm wire (75 turns), meaning that the no-load speed at 5V would be sub 1700RPM. That could be a bit of a problem since the expected max finger speed would be 3400-3500RPM at the motor, so it might mean that power is harnessed from the fingers, causing resistance, or perhaps damage something.

0.25mm wire at 41 turns would have a no-load speed under 3250RPM (460RPM at pulley) and consume 128mW. Additionally, 0.25mm wire is more popular and should be more reliable to wind due to the lower turn count. The lower resistance should also mean it's easier to generate haptic waveforms.

kelvinA

kelvinA I have more confidence that my simulation is set up correctly if there actually is a standard size that's only 0.1mm smaller on the ID.

I have more confidence that my simulation is set up correctly if there actually is a standard size that's only 0.1mm smaller on the ID. The stator is shorter because the expected PCBA thickness is expected to be 4.95mm. Additionally, I added an extra 4mm to the belt length of Tetrinsic that I've now removed. All in all, this means that the rotor has to decrease from 42mm to 36-37mm.

The stator is shorter because the expected PCBA thickness is expected to be 4.95mm. Additionally, I added an extra 4mm to the belt length of Tetrinsic that I've now removed. All in all, this means that the rotor has to decrease from 42mm to 36-37mm.

Each SS-430 yoke could potentially cost only £1.50, as the coil length is 0.707m and 14 lengths could be cut from a 10m roll.

Each SS-430 yoke could potentially cost only £1.50, as the coil length is 0.707m and 14 lengths could be cut from a 10m roll.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.