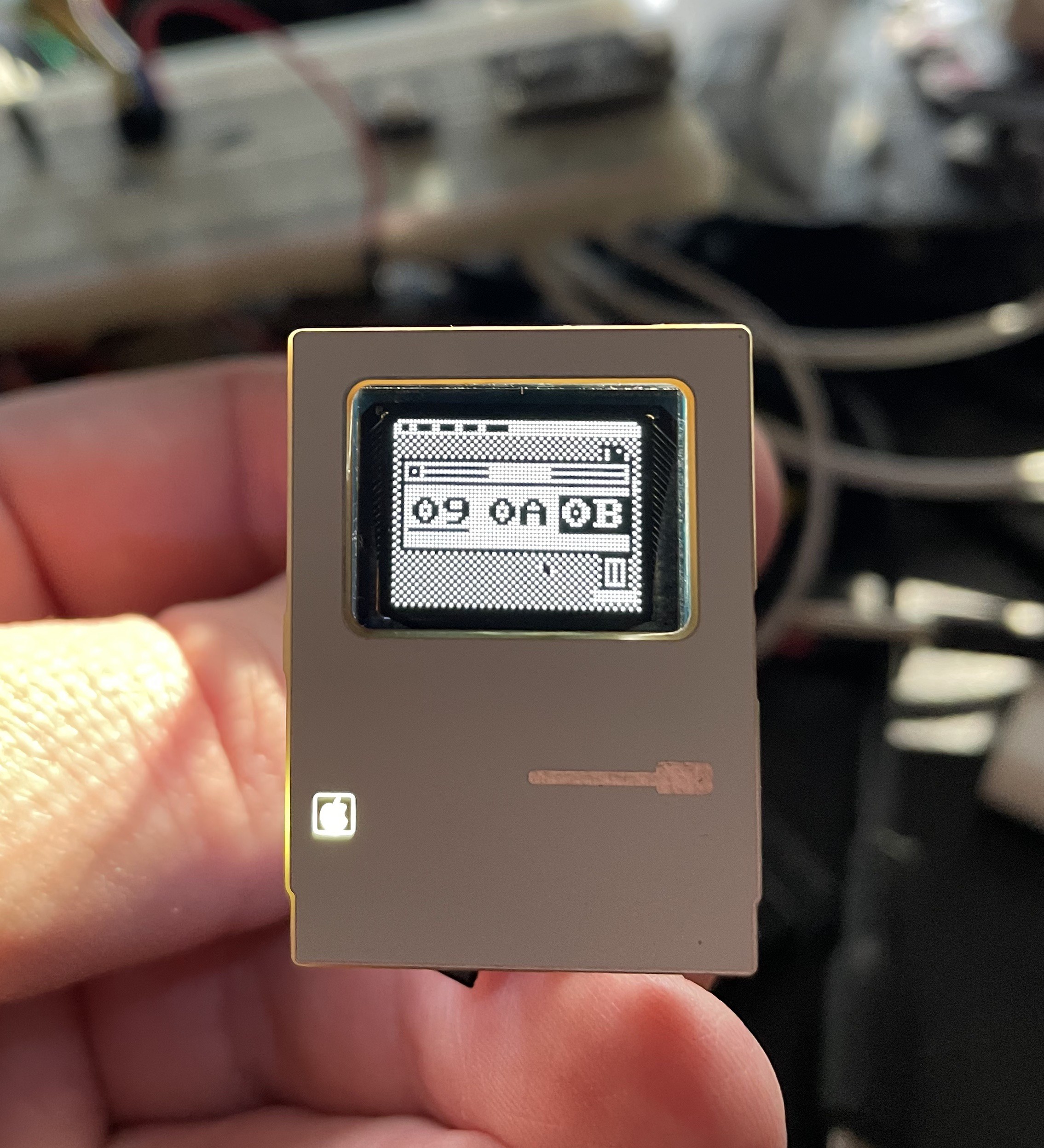

My new boards arrived! After a bit of eval, I'm feeling very confident that they do what I want them to. Also, cutting the additional square out for the Apple logo looks very nice, and I'm pleased with how it turned out.

Most of the components on the board are SMC, so I'll squeegee some solder paste on, place the components and either bake in an old toaster oven or use the hotplate I got for the purpose.

The thing I can't do via reflow is solder on the display. As previously noted, I stumbled into the idea that I could just wick the pins onto the contact pads with a bit of solder, but aligning the display was going to be an issue.

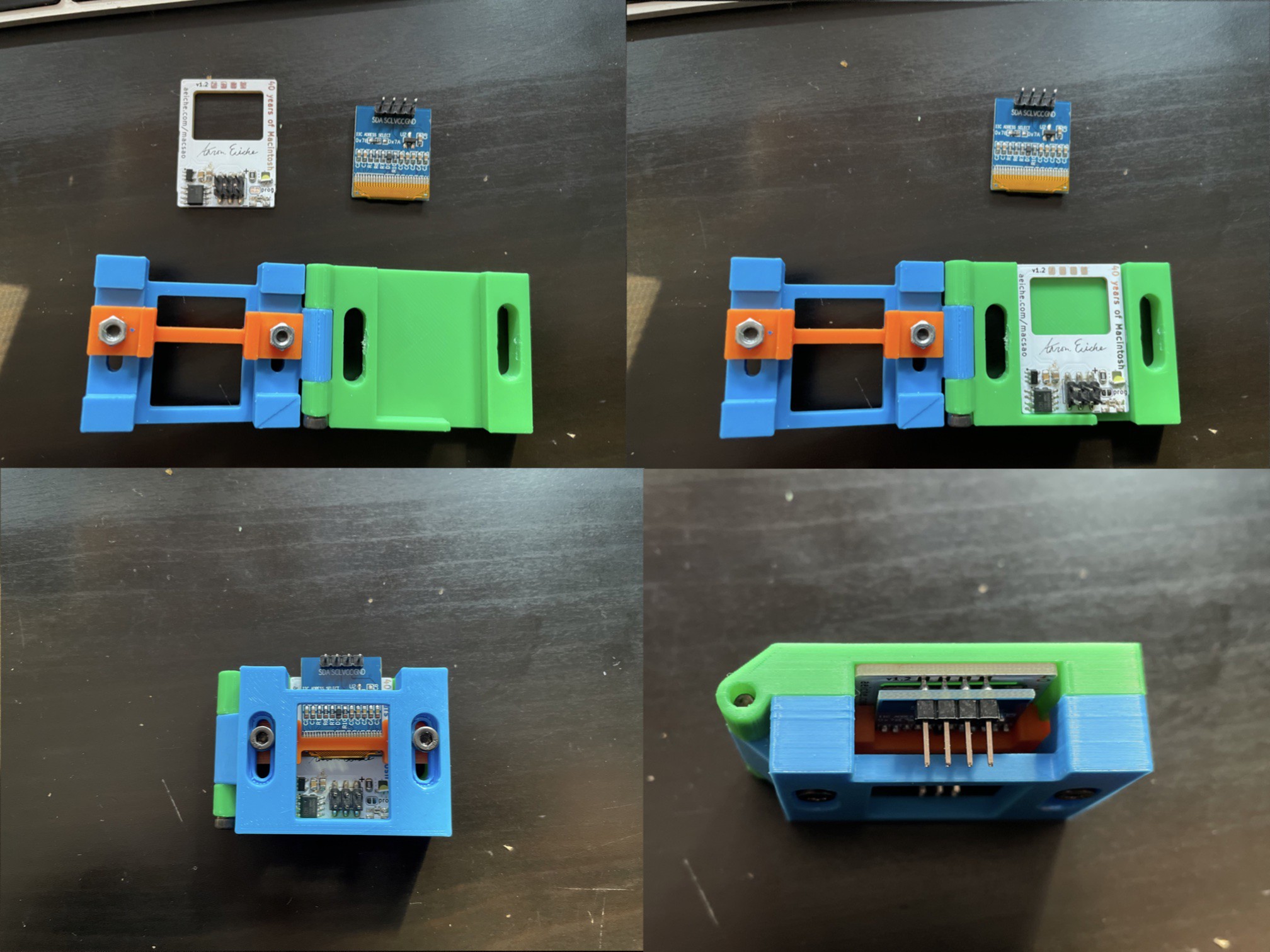

Of the many benefits to the home enthusiast 3D printing has bought, one of them is custom jigs. A simple tool custom made to help you accomplish positioning or accuracy.

I wasn't entirely sure how to put mine together. I needed to position the display, and the PCB, make room for the button which is at the bottom, and of course leave the top open so I could actually solder the thing.

I made a lot of jigs. I eventually settled onto a fold-over setup. The bar that sets the position rests on the placement of the SMD resistors

Eventually I managed come up with a working design. The operation is pretty simple. Put in a reflowed board, close, slide in a display. Solder the pins.

The second display I've tried to place with this fit very snugly in the orange display-positioner. So I can also pre-place the display. I'm tempted to make one more run of the green base, cutting open the back so I can check the display from the front-side, but if I've tightened the screws right it should be repeatable.

And here is the first product:

Gotta finish the firmware. Gotta complete the documentation.

“Jiggery pokery!” said Harry in a fierce voice. “Hocus pocus — squiggly wiggly —”

Aaron

Aaron

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.