Hello people of the internet and...

(To be perfectly honest i think this is how i'm going to start my posts from now on)

In the last post i showed the servo mount to be working but when it comes to injection molding, it's another issue. My original plan for injection molding was using an aluminium mold that would be created via milling. Ah yes, but there was an issue. Our milling machine only has 3 axis which means the slanted curves for the interlocking joints is useless and needs to be changed. So after a long attempt to change how it works, i found that a tab system would be better than slanted. Therefore no matter what option we chose for the mold, it would turn out fine.

Now, moving beyond that, i had to do a lot of reading to understand how injection molding works. Dan, the resident engineer, was kind enough to give me the $2400 book about injection molding.

After reading the table of contents, my face turned to this...

Yup, i have almost no clue what i read but i did understand the basic procedures of it. And on top of that, i'm a month ahead of schedule since the molding machine is not up yet.

But just because i'm ahead doesn't mean my job is done. So back to Fusion 360 i go!

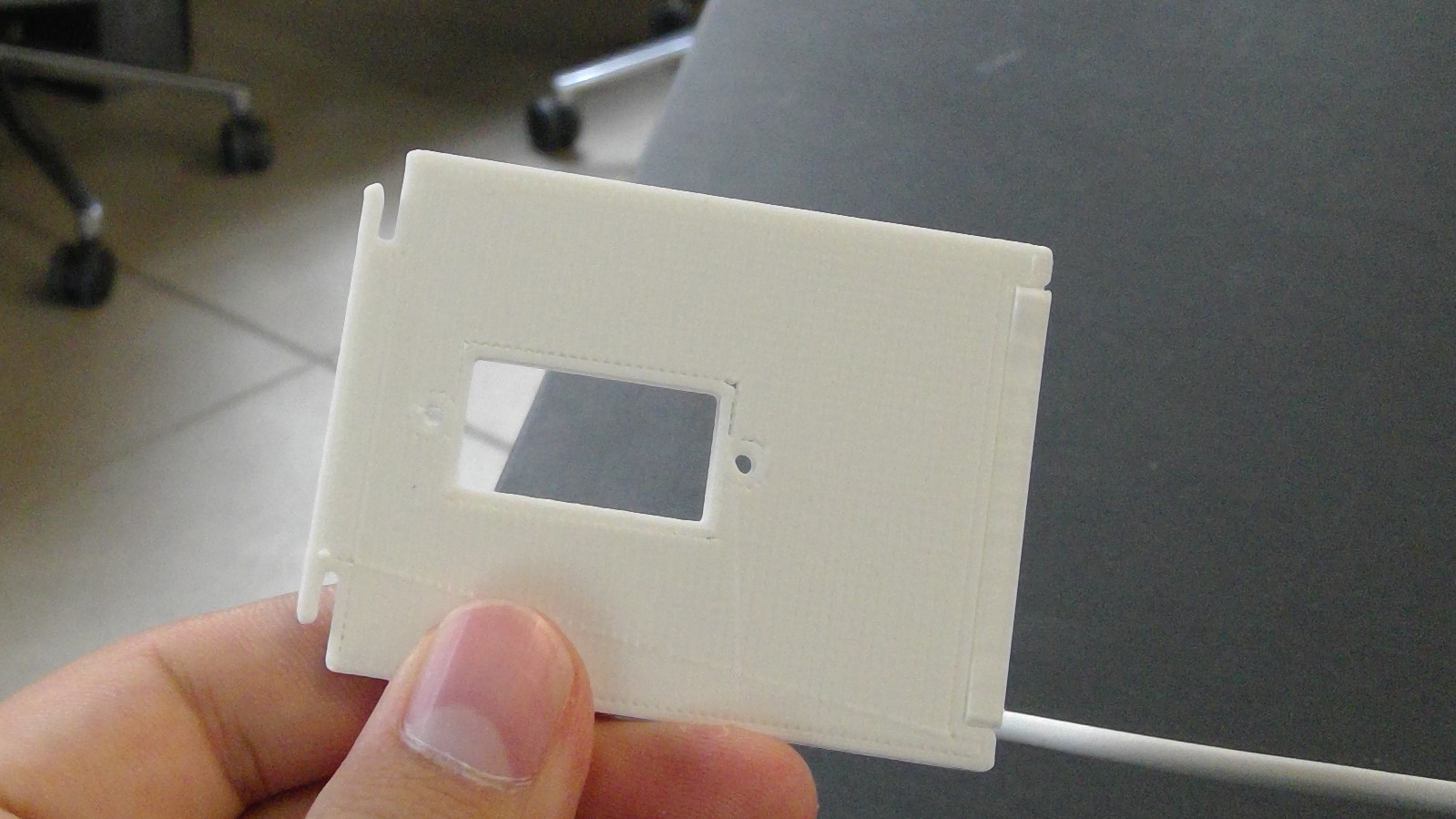

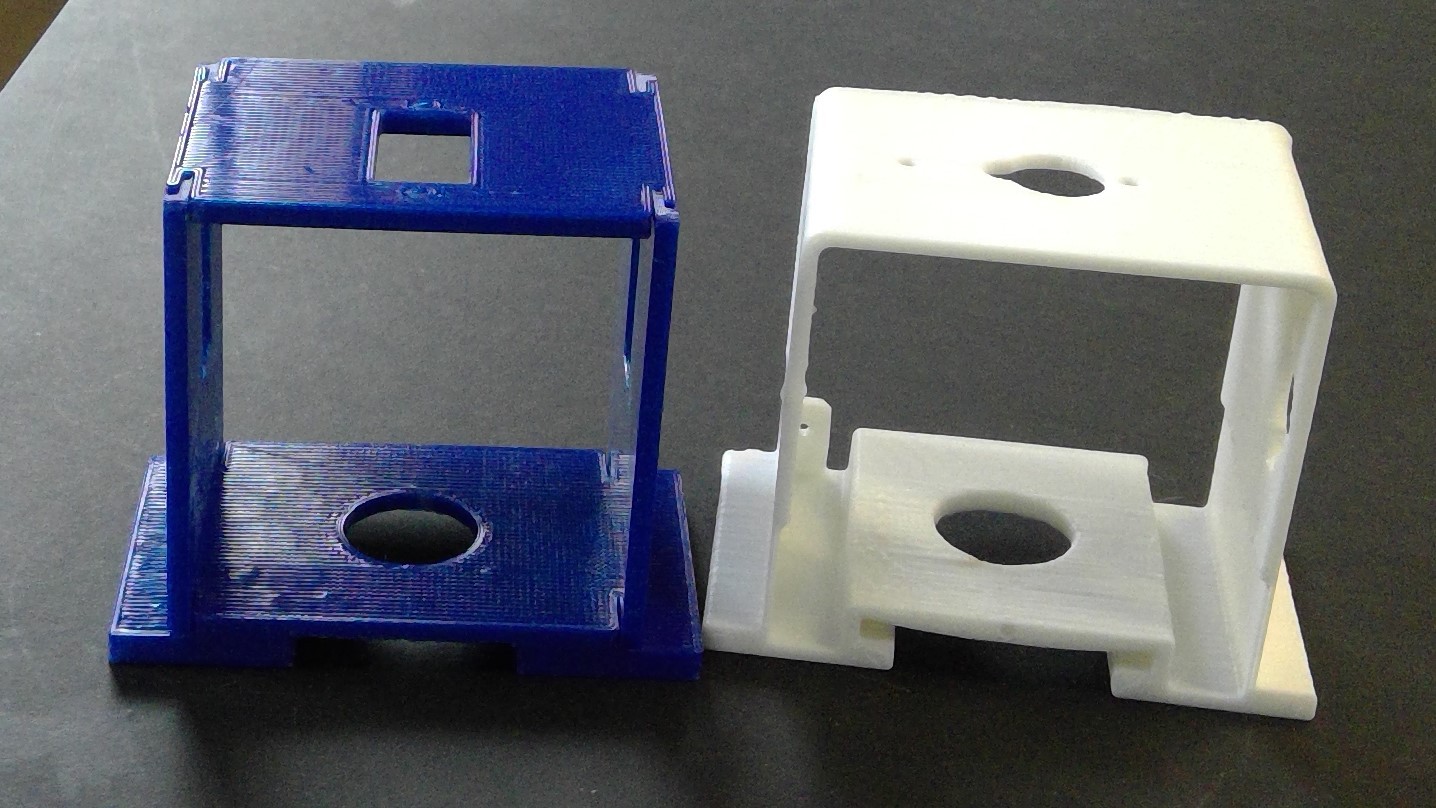

And after multiple different versions of my body, I was able to create the positive of my mold.

Nice

This is where ill leave for this week, bye bye

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.