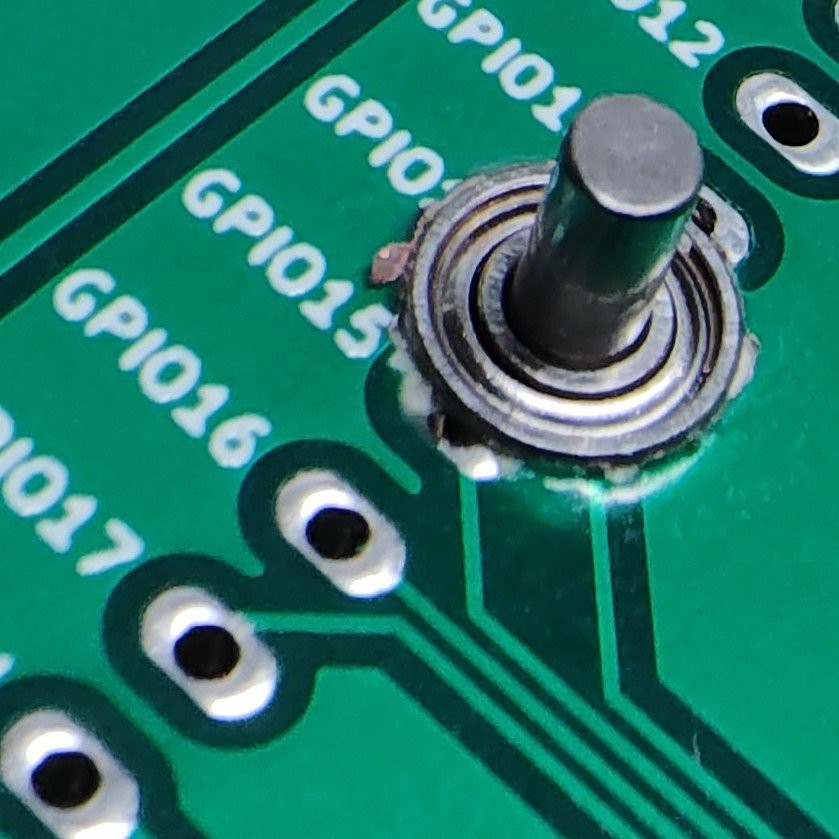

I had some 2mm ID x 6mm OD x 2.5 mm wide bearings on hand and a 2mm x 8mm shaft that fit. Designed some 3d printed parts around these to hold the magnets. Magnets were 6mm x 1.5mm that were on hand as well. Drilled a 5mm hole in scrap PCB to test, slightly skewed. Seems to spin okay with just bearing and shaft but it's hard to hold. Test PCB was 100mm x 60mm vs 90mm x 50mm. Spun nicely when held in vice. Clearances were a bit loose on first batch of 3d printed parts. Magnets slipped out and shaft bore was a bit loose. Added the jolly wrencher logo for some HAD bling.

mulcmu

mulcmu

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.