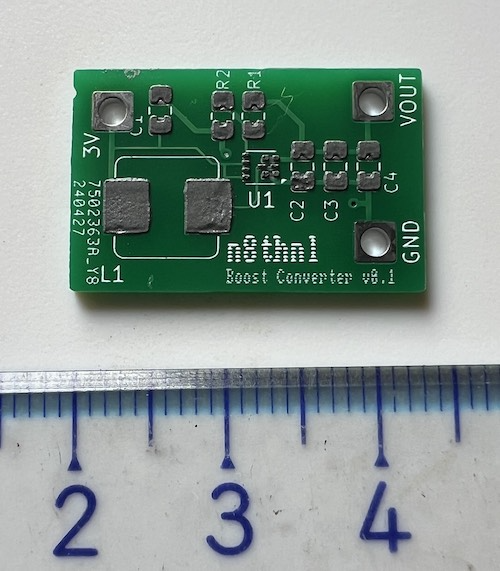

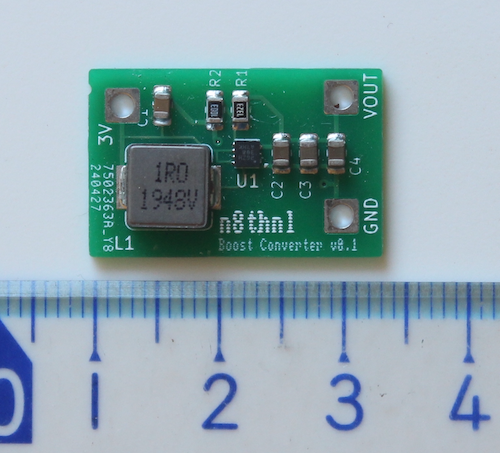

NOTE: I'm currently working on curating the files/tags on Github in order to match the version numbers that are posted here.

Check the files in this project for the gerber zip which can be uploaded to JLCPCB (or any other pcb fabricator). No special pcb instructions are needed for this board.

v0.2 is currently in progress (see first picture in the gallery). As of 6/30 I actually have the PCB + parts and just need to find the time to assemble it. Will post a worklog once that's done.

Nathaniel

Nathaniel