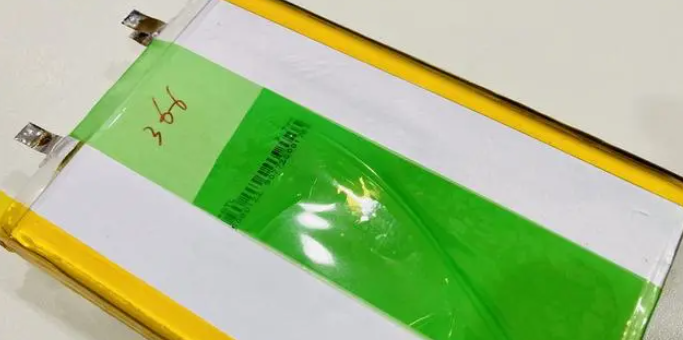

I accidentally found more than 10 pieces of ATL ternary soft-pack lithium batteries I bought 10 years ago (purchase record in September 2010), with a nominal capacity of 5AH. When I measured the voltage, it was quite normal, mostly around 3.65V, and a few were around 3.85V.

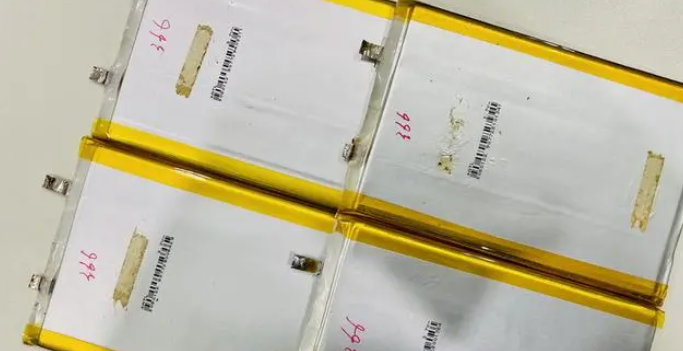

After counting, I found that 13 pieces of battery with a voltage of about 3.65 can be put together, so I chose the ones with the smallest voltage difference possible, and put four pieces in a group. I first tied them up lightly with battery termination tape, and prepared three groups in series to form a 4-in-3 battery pack.

According to the planned battery polarity direction, stack 3 groups of 12 cells together, and be sure to pay attention to the insulation of the cell electrodes. According to the stacked dimensions, make the shell with 3mm thick wood and wrap it with imitation carbon fiber stickers.

Affix 3-string same-port protection board to one side of the housing.

3 series of 40A protection board, with balancing on the same port. Does it feel a bit over the top? However, safety comes first!

Group 4 cells in parallel, confirm that the welding is reliable and the polarity is correct, and then connect 3 groups of parallel cells in series to form a 4P3S structure.

Weld the battery lead wires and the protection board connection wires. Pay attention to reliable welding between the poles, no cold welding, and no short circuit risk. Measure the balancing cable sequence to make sure it is correct, and plug in the protection board balancing cable.

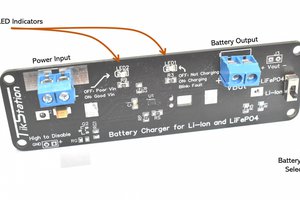

Use a 12.6V charger to connect to the battery output terminal (same port protection board, the output terminal is also the charging terminal), charge and activate the battery pack. Measure the voltage between the positive electrode of the battery and the negative electrode of the battery cell, and measure the voltage between the positive electrode of the battery and the negative electrode (P-) of the protection board output. Normally, they should be consistent.

After confirmation, use hot melt glue to fix the internal wires as much as possible. Charge at a charging rate of 0.1C (20AH battery, 0.1C is 2A). Because it is an old battery, it needs to be kept with someone during charging, and pay attention to the changes in the voltage and temperature of a single battery cell at any time to prevent accidents.

After charging, the battery pack voltage is measured to be 12.61V, the battery cell voltage is as shown in the figure, the voltage difference is 0.01V, and the acceptance is qualified, and it is completed!

Installing the battery and 500W modified sine wave inverter on a wooden board is quite good for lighting and charging mobile phones/laptops. The measured no-load current is 0.07A and the maximum conversion efficiency is 97%. These are things that pure sine wave inverters cannot do!

erinee

erinee

Walid Issa

Walid Issa

Frank Adams

Frank Adams

Quinn

Quinn