https://www.homedepot.com/p/HDX-No-Pump-Sprayer-Wand-190751/322448067#overlay

The lion kingdom finally took another step towards better thermal management. The original idea with the nano misters

https://hackaday.io/project/180609-personal-air-conditioning-with-mems

was to use those as a powered spray bottle. They didn't prove powerful enough.

The next step was an electric gardening sprayer. When it works, it's like having a garden hose in the apartment. It cools down a lion in no time. It's definitely the right idea but there are problems. The pump has to be primed or it won't spray anything. The only way to prime it is to keep it below the tank & really pray. It's not easy to get the tube filled. It might be easier if the tube was transparent. Eventually, it could only be primed with running water in the sink. Blowing into the inlet seemed to help. A pump closer to the inlet would be ideal.

Once primed, it has a valve which tries to hold a vacuum unless the trigger is down.

Eventually, the valve would no longer retain a vacuum after a certain amount of time. It's 1 of those valves which really has bee dick margins. The pump would have to be below the inlet so it won't need the valve. If the nozzle ends up below the pump, it'll drain the tank. It would still need a valve for the outlet. The lion kingdom has solenoid valves specifically for air.

If any air enters the intake, it has to be primed again. The intake has to be really firmly submerged in the tank. It takes some effort to make sure it doesn't bounce around & ingest air. There is a special tank with the right threads to mount the intake.

The extremely short hose also makes it hard to keep it submerged. It's not long enough to spray the mane or the back. All the fittings are for the same 3mm ID x 5mm OD tube that the swamp cooler uses.

Finally, the nozzle doesn't lock into a useful angle. It has to be held sideways to stay in a useful angle.

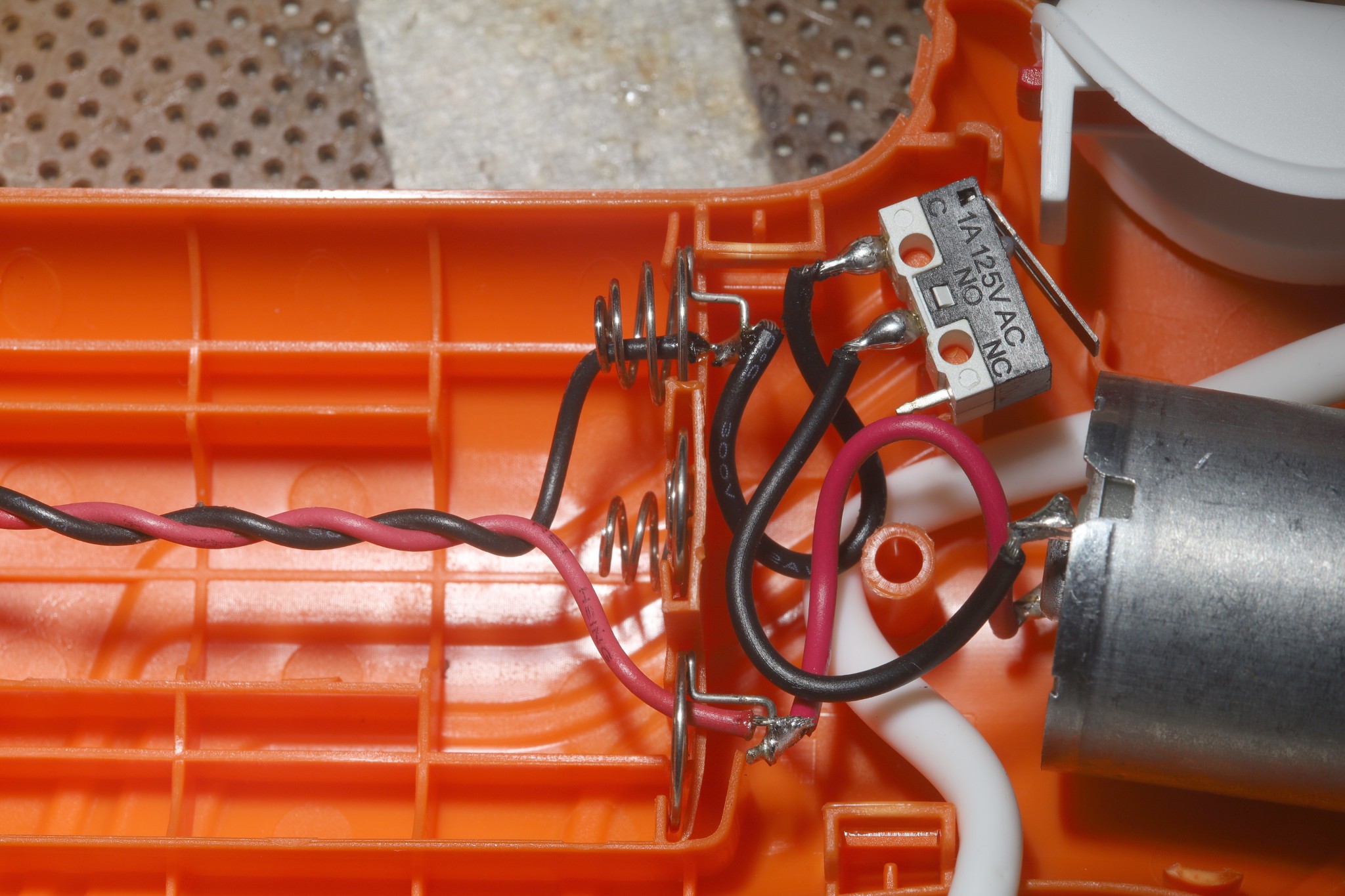

In the teardown process, the lion kingdom tried to press in the tabs to extend their life. The case comes apart pretty easily when pressed in the right places.

It's 1 of those gadgets which doesn't work with NiMH because the terminals are slightly off.

Eventually got a temporary power solution. The optimum nozzle angle evolved to point right back to the handle.

The nominal power usage is 1.5A at 4.8V.

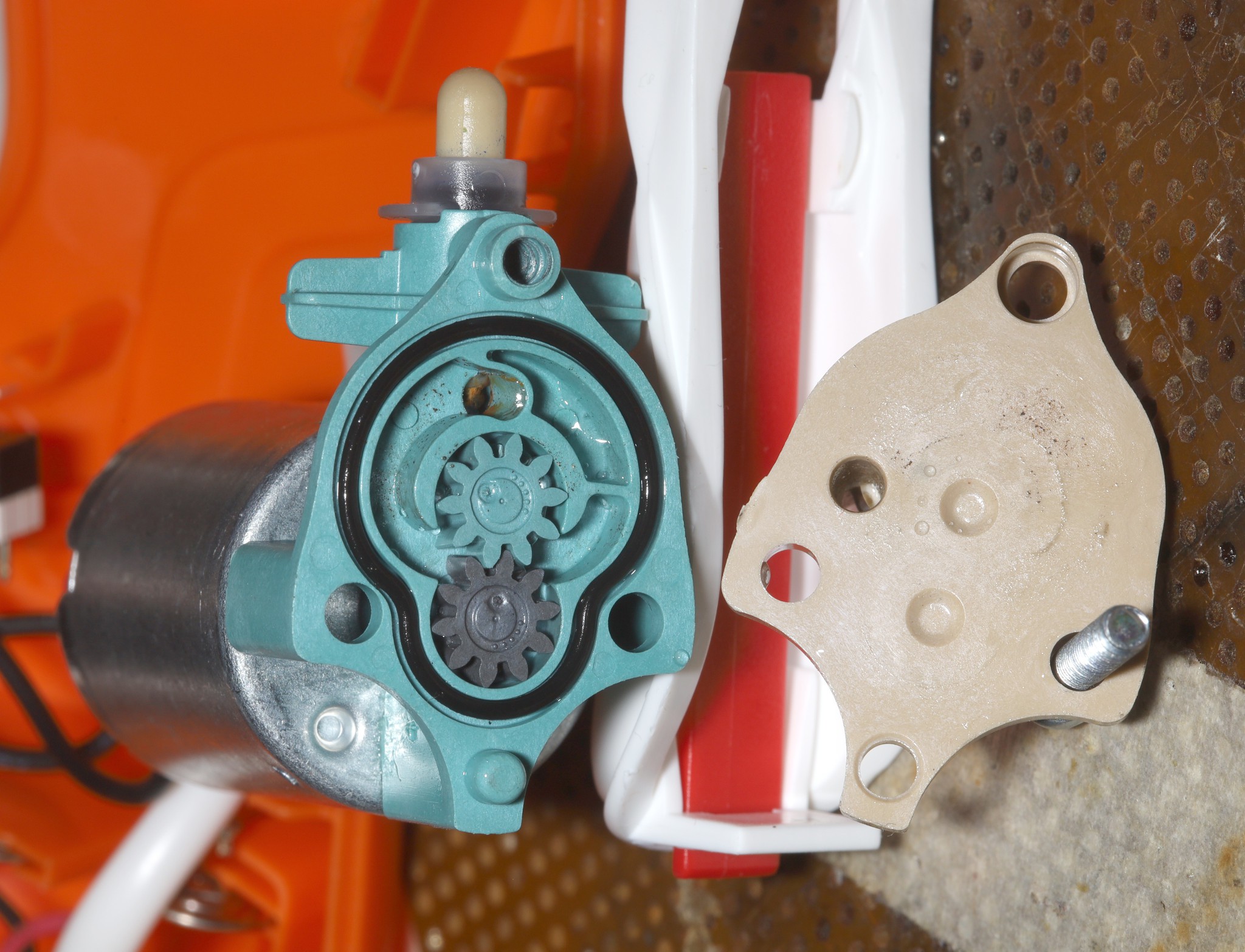

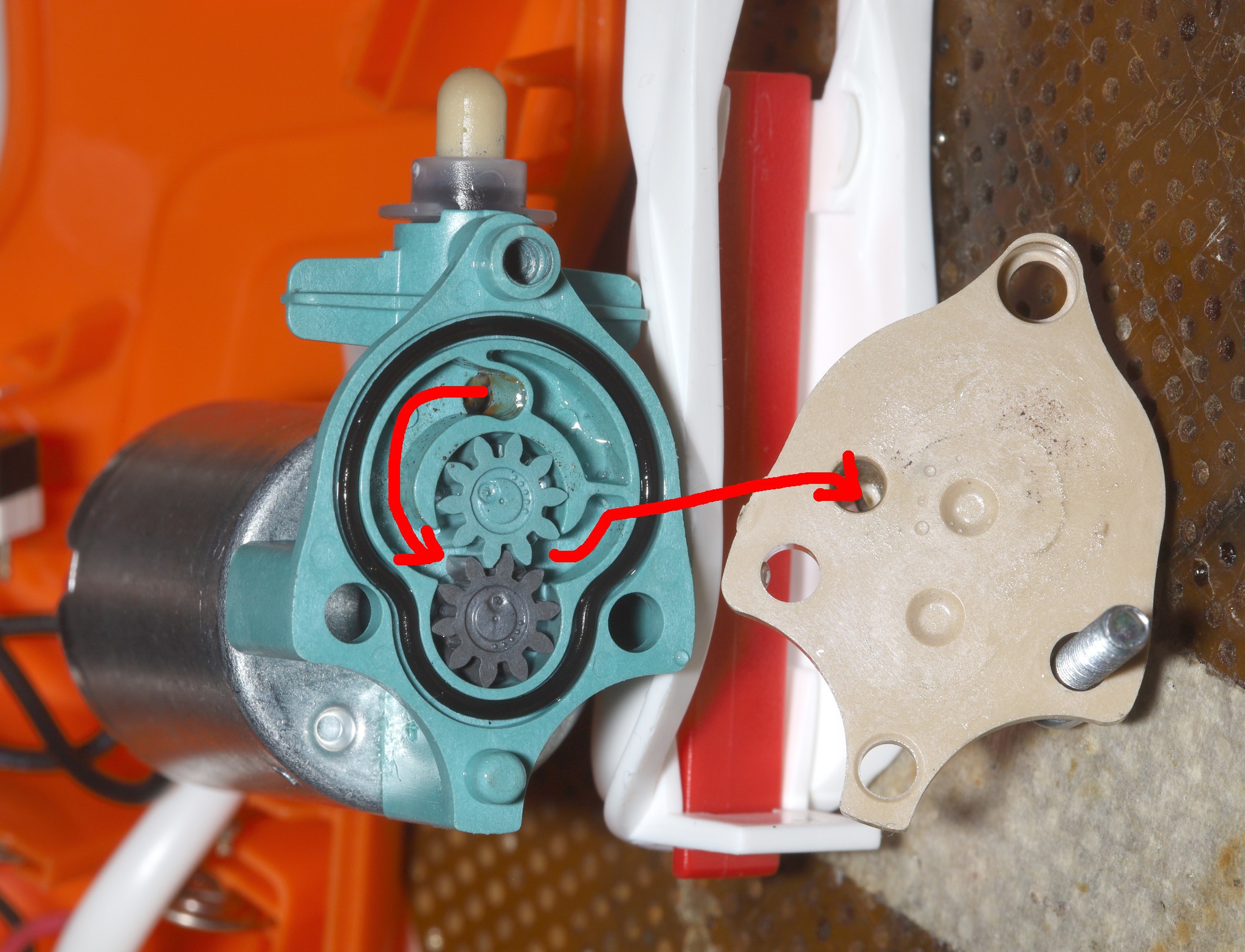

The pump is user serviceable. It has 2 gears meshing the water through.

1 gear is direct driven by the motor. The other gear is on a plastic bearing. Also visible is the outlet of the pesky valve.

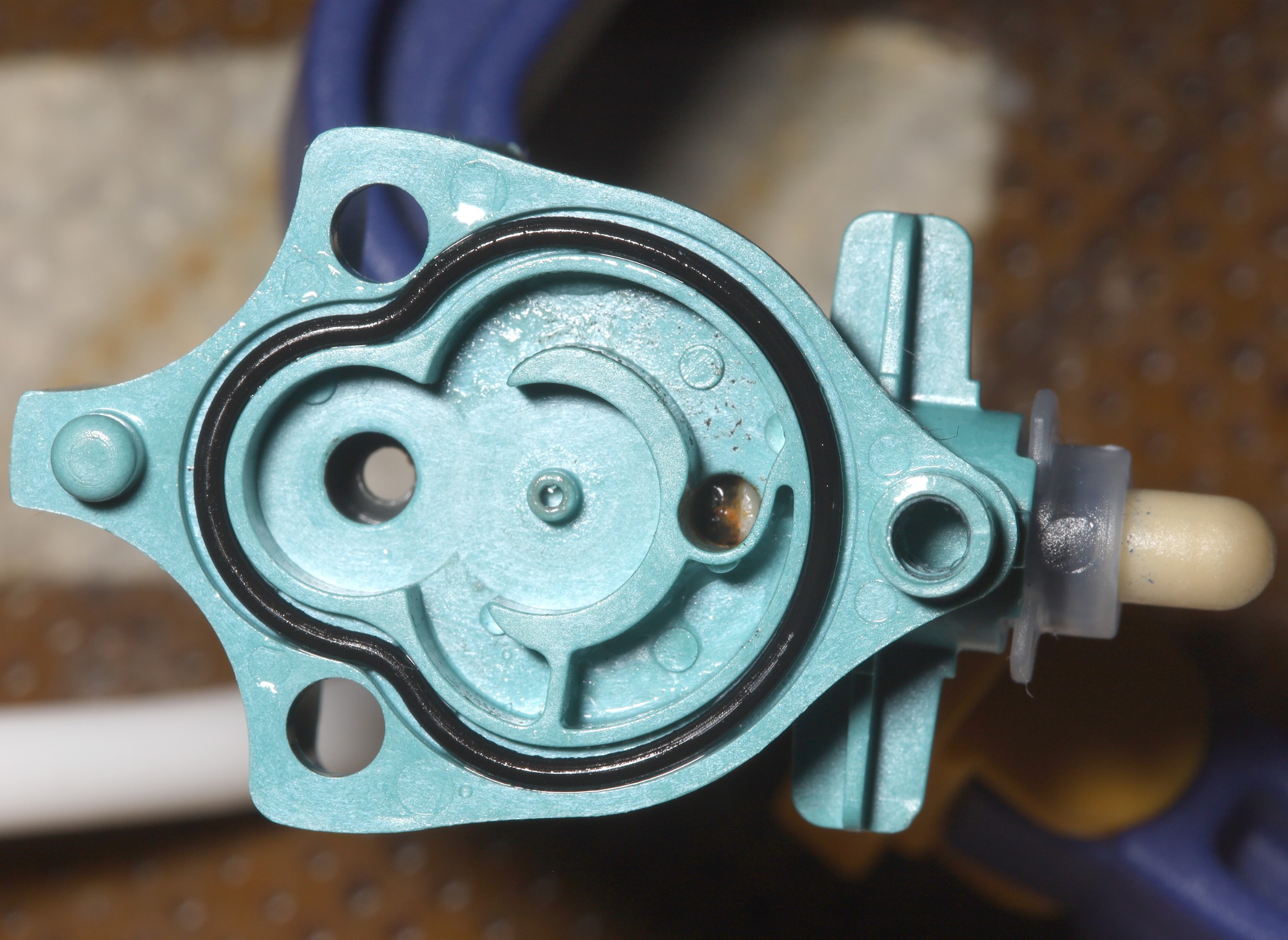

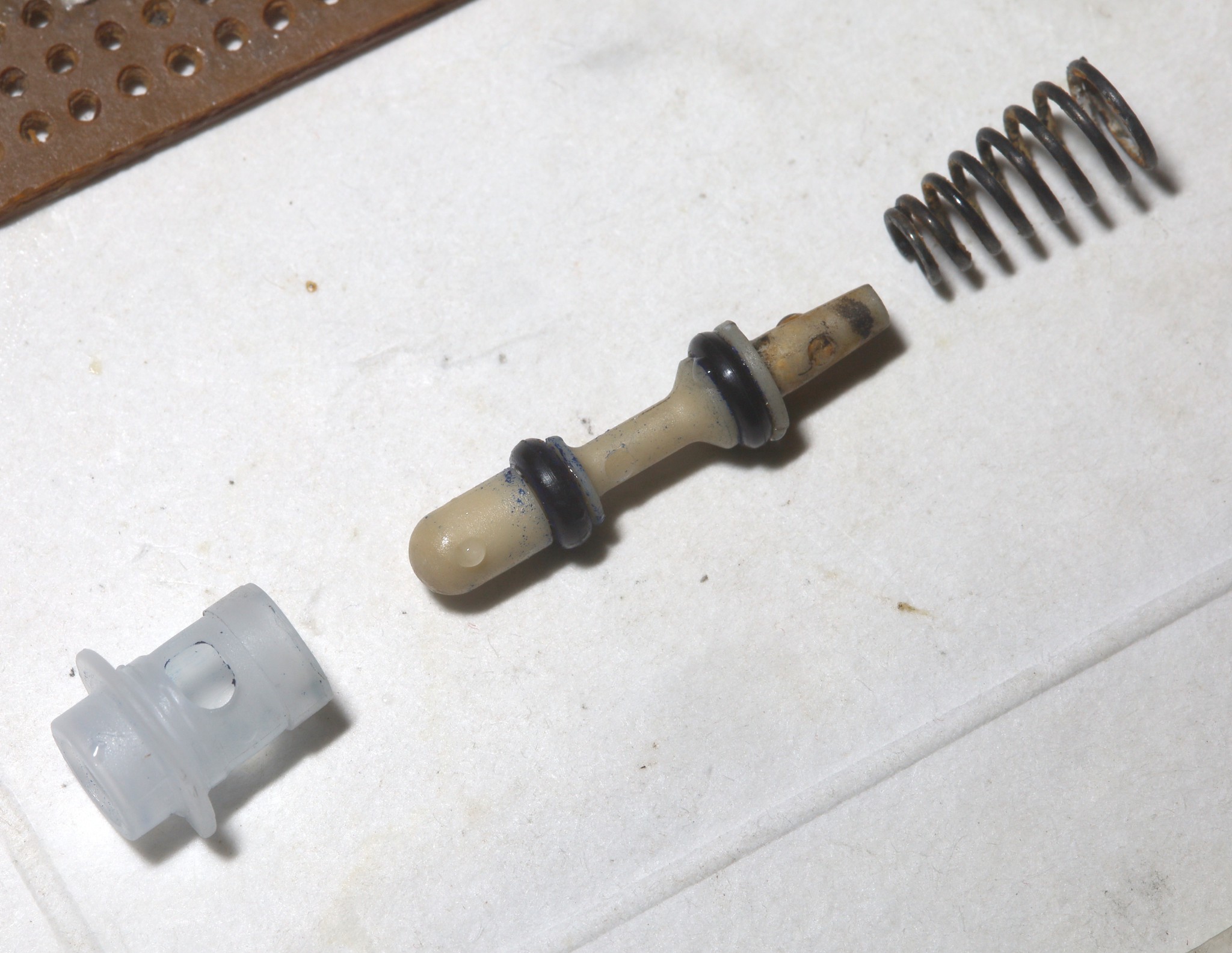

Prying off the teflon bit slides out the complete valve. It can be fixed open by removing the spring. The O-rings are where the magic happens. The big one presses against the pump inlet to hold a vacuum. The little one keeps water out of the electronicals. The spring originally had brown grease.

Cleaned off the brown grease, dumped silicone grease on all the O-rings & spring.

This seemed to restore the valve functionality, for the moment. Also put silicone grease around the motor bearing to try to keep water out.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------

Wally has another variation on the theme which includes a matching tank. The lion apartment has a case of water tank overload. A better way might be printing an adapter for 1 of the existing tanks.

------------------------------------------

The key desires are a longer tube, a pump below the intake to stay primed, a smaller & better aimed nozzle, external battery which sits on the tank. It could probably be done with the existing trigger motor assembly. Another idea is to make the pump close to the tank & have a long outlet tube going to a remote nozzle with the trigger. The pump valve would have to be disabled & an in line solenoid used instead.

Lengthening the intake tube & securing the intake is job 1, no matter what. Shortening the nozzle is job 2. That's a single epoxied piece. It would require a splice joint, probably 3D printed. Fixing the nozzle angle could be done by bolting a detent on the paw piece.

The pump has screws which could possibly disable the valve.

This could be the basis for running in Fl*rida. It would need a remote nozzle on a pole with all the hardware near the tank. The camera controller could aim it. A new button could fire it.

The sprayer is so effective, it might be worth just building one with the right parts. It would be expensive.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.