This project was born out of a desire to recycle batteries. Specifically, 18650 Li-ion cells. These are by far the most common batteries in the world today, although LiFePO4 is coming up through the rear due to their lower cost and widespread adoption in more recent electric vehicles.

If you're into battery hacking, you've probably seen these around. They are everywhere. They are in laptop batteries, e-bikes, phone power banks, e-scooters, modern wheelchairs, home appliances, - you name it.

and why is that? Well, these overcame the memory-effect of Ni-mH batteries, the darling chemisty of the 1990's. Before that, it was Ni-Cd (Nickle-Cadmium). But what makes Li-ion so special?

Lithium is the lightest solid element on the periodic table. It only has 3 protons in its nucleus. So if you can add an electron to ionize it- then you have the lightest conducting solid known to humans. This is the promise of Li-ion (Lithium Ion), as it's weight to power ratio is the very best of all battery chemistries. It also does not have the "memory effect" of older chemistries, so it does not need to go to zero percent before recharging.

In fact, letting these batteries drop to zero is very bad for them. This old wives tale of "let it go to empty before recharging" is a fallacy I combat in every conversation I have with the layperson on battery care.

(please note, I'm not a chemist or physicist!)

So what are the drawbacks?

First, Li-ion cells are prone to explode under certain condititions. If cells fall below 2.9V (and then gets recharged) or it gets recharged over 4.3V, very bad things can happen:

Hoverboards and vape pens are one example of many stories where these powerful batteries go up in flames.

This can be due to a number of factors, but the most common are lack of (or failing) protection PCBs and overdischarge/overcharge.

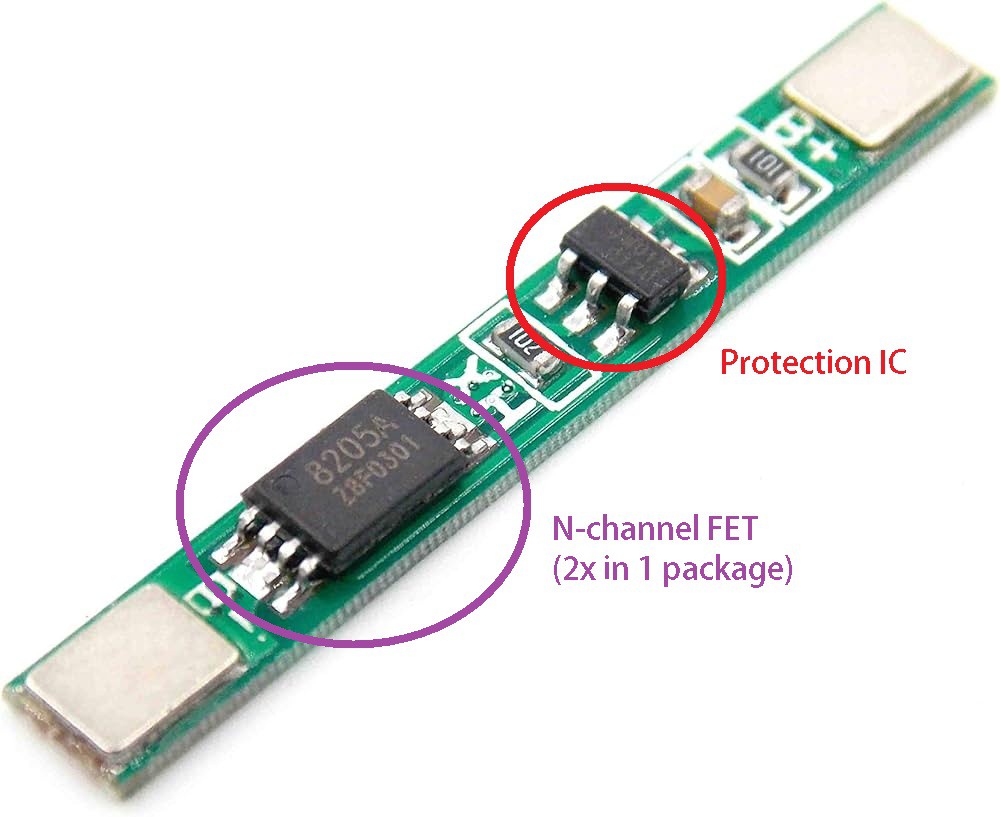

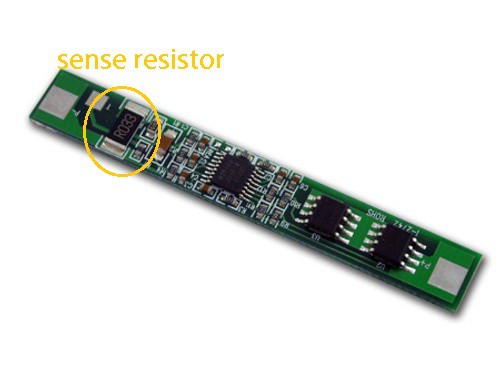

In order to be safe to use, there needs to a be a monitoring circuit attached to the battery pack. This circuit (the SOT-23-6 above) is usually hooked up to 2x N-channel FETs. Any number of FETs can usually be connected in parallel for higher current. The circuit checks the voltage level and turns off the FETs (which act as solid state on/off switches) if the voltage is too high or low, or the current is too large.

Not all monitoring ICs are created the same. The best ones incorporate a sense resistor to measure current and also use an extrnal NTC thermistor to keep an eye on the temperature of the cells. If they sense an error, the FET gates go low and there is no longer a conductive path for the battery pack to reach the load. Some will incorporate a nice thermal fuse as an additional safety.

Sounds nice, doesn't it? But what happens if the error is temporary, or a user disconnects the pack to make a DIY cell?

In most consumer lower-expense systems, the protection PCB will be de-activated until the correct cells are reconnected and a charger is plugged in. The "dumb" hobby RC chips work this way.

However, the stuff in more expensive equipment is different.

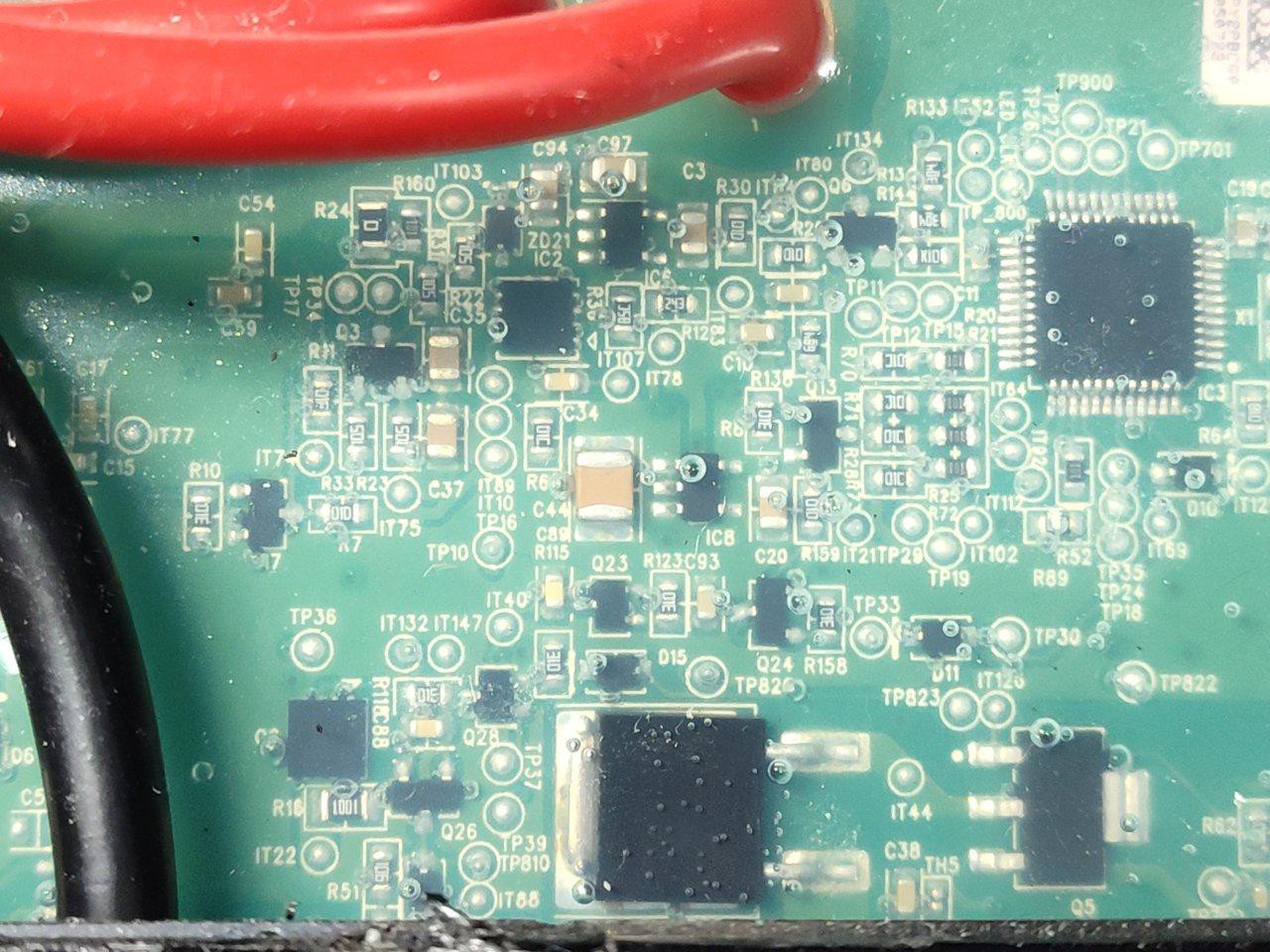

This is essentially an e-bike battery used for a power wheelchair. It has a microcontroller - essentially a mini computer- as well as a very fancy BMS (battery management system) chip. It monitors the entire lifespan of the battery - how many times it has been charged/discharged (cycled) since the factory, every time a voltage threshhold is reached, it's temperature over time, and much more. It sends all this data to an onboard CPU in the bike / wheelchair controller and also gives an authenticity serial number over the data bus. Whoa!

Modern laptops do the same thing. And they usually use a family of TI (Texas Instruments) chips beginning with "BQ" to do this:

what SUCKS about this, is that these chips have essentially a "suicide" mode. The data is encrypted in an off-board EEPROM sometimes, and if the battery pack does anything unusual - say, someone trying to repair it - the chip will suicide and need to be returned to the factory.

We are told this is for our "safety." But most consumer electronics don't do this. and what's the result?

absolutely massive environmental waste.

now I don't pretend to have the solution to such a large global problem, but I can start by doing my part to make my own battery packs - using recycled 18650s. These cells are being thrown out everywhere these days, and they can be pulled from dead battery packs around the house too.

All we need is a decent spot welder to make them useful...!

CriptasticHacker

CriptasticHacker

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.