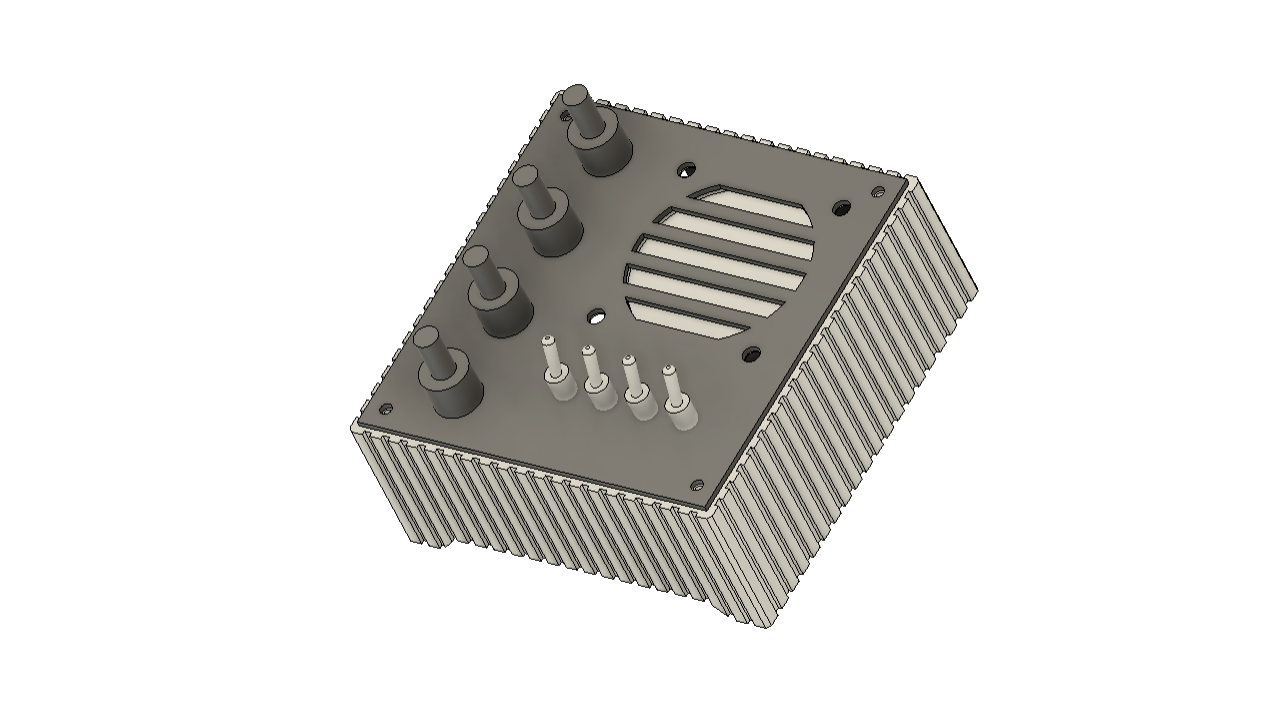

3D MODEL

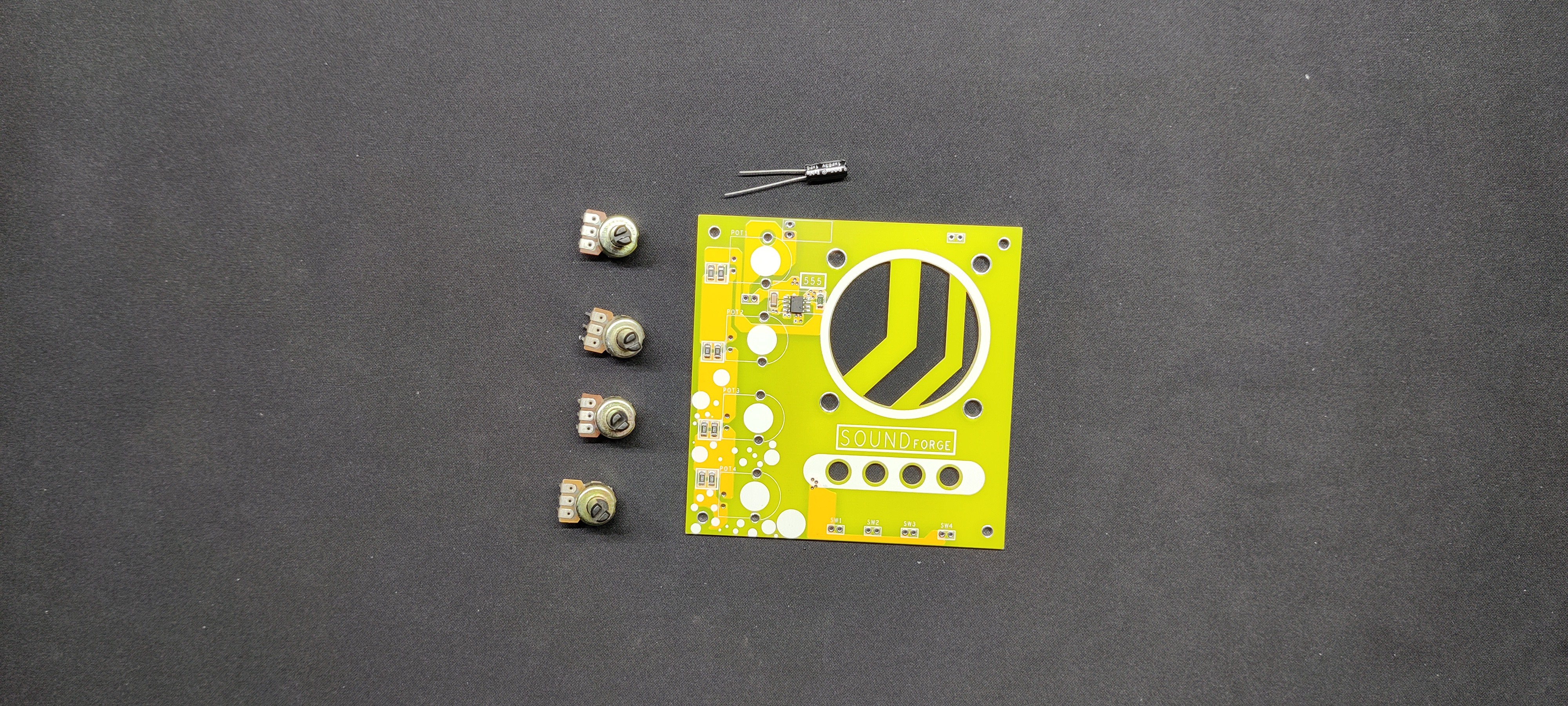

We begin by creating a 3D model in Fusion360 for the Sound Forge Project. To do this, we added the speaker, potentiometer, and lever switch to the model first.

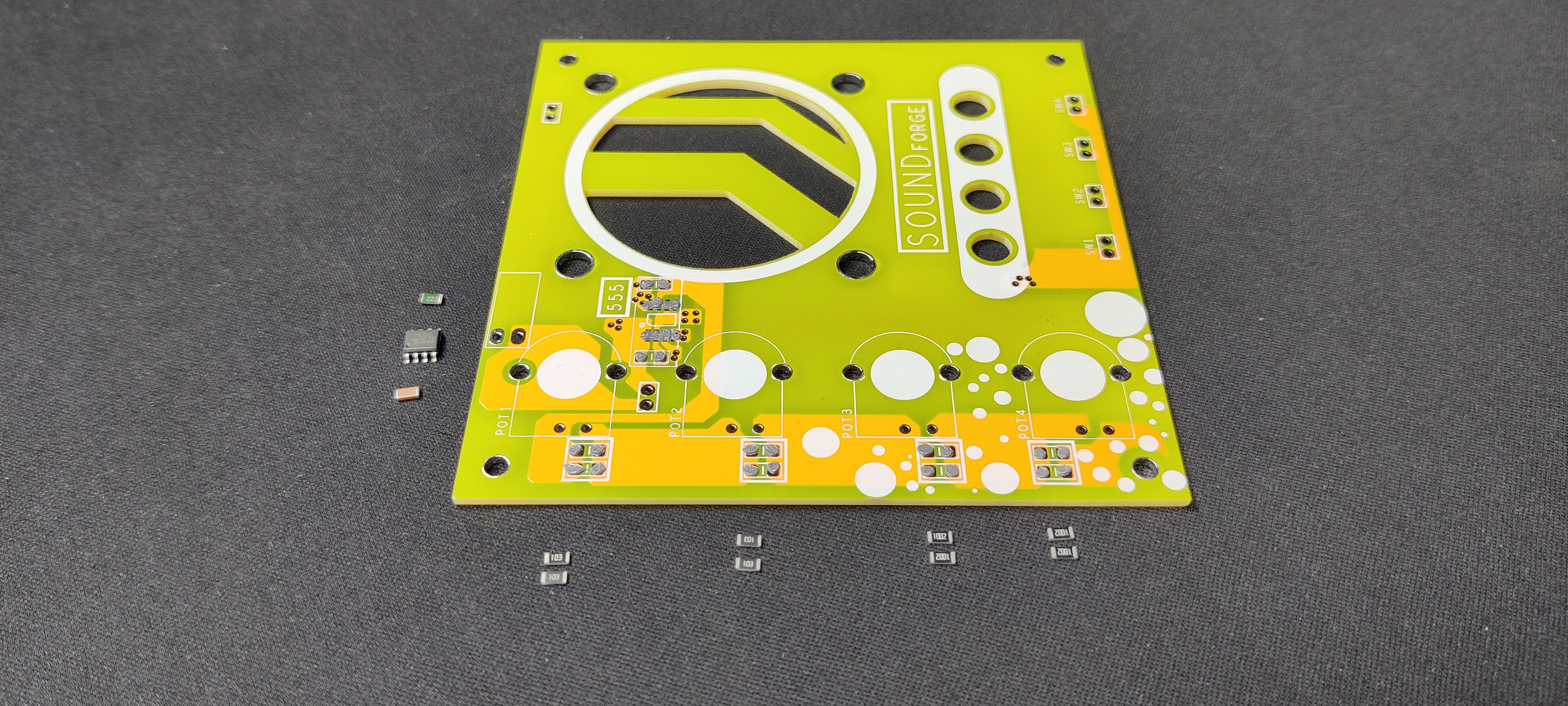

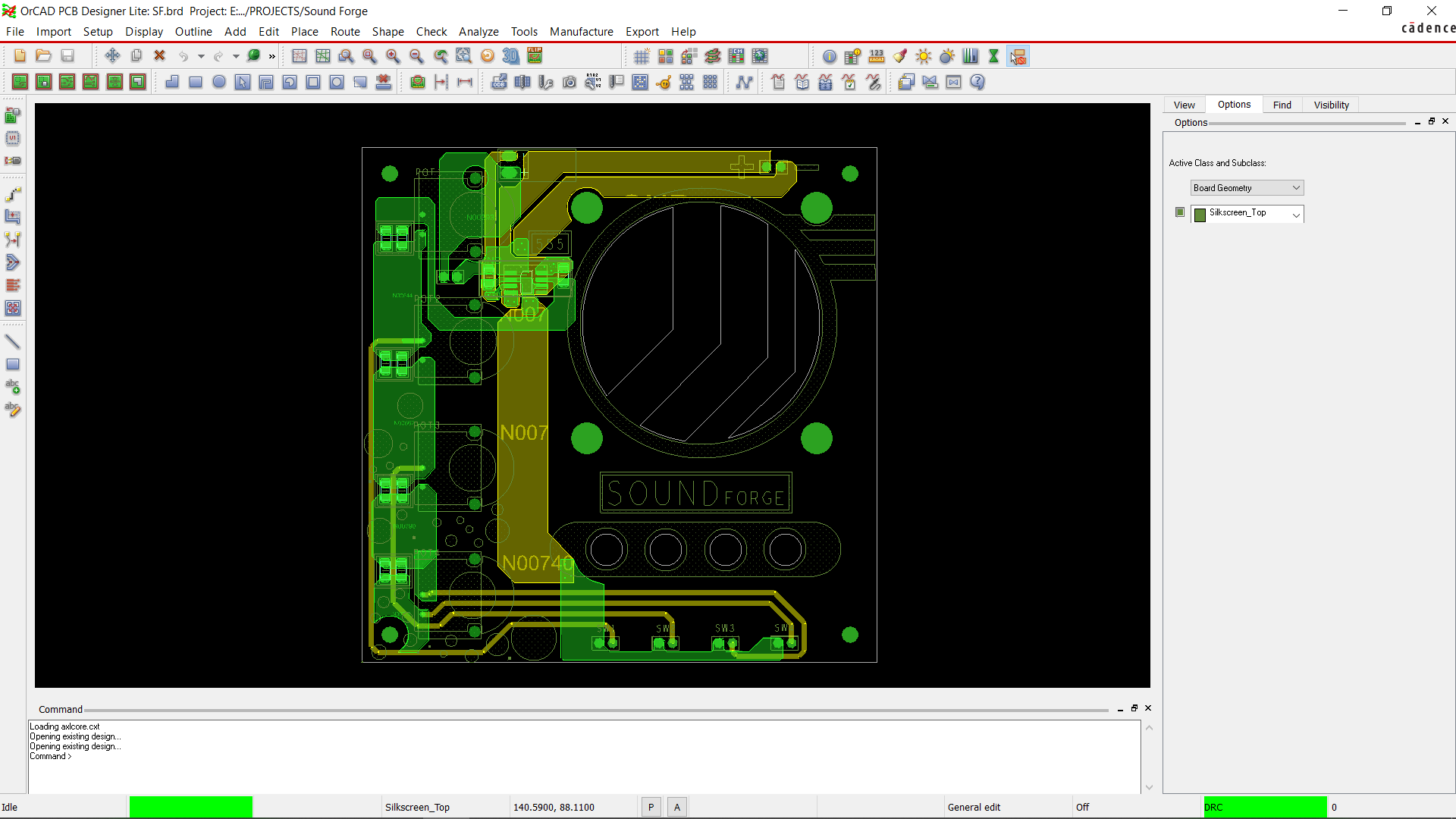

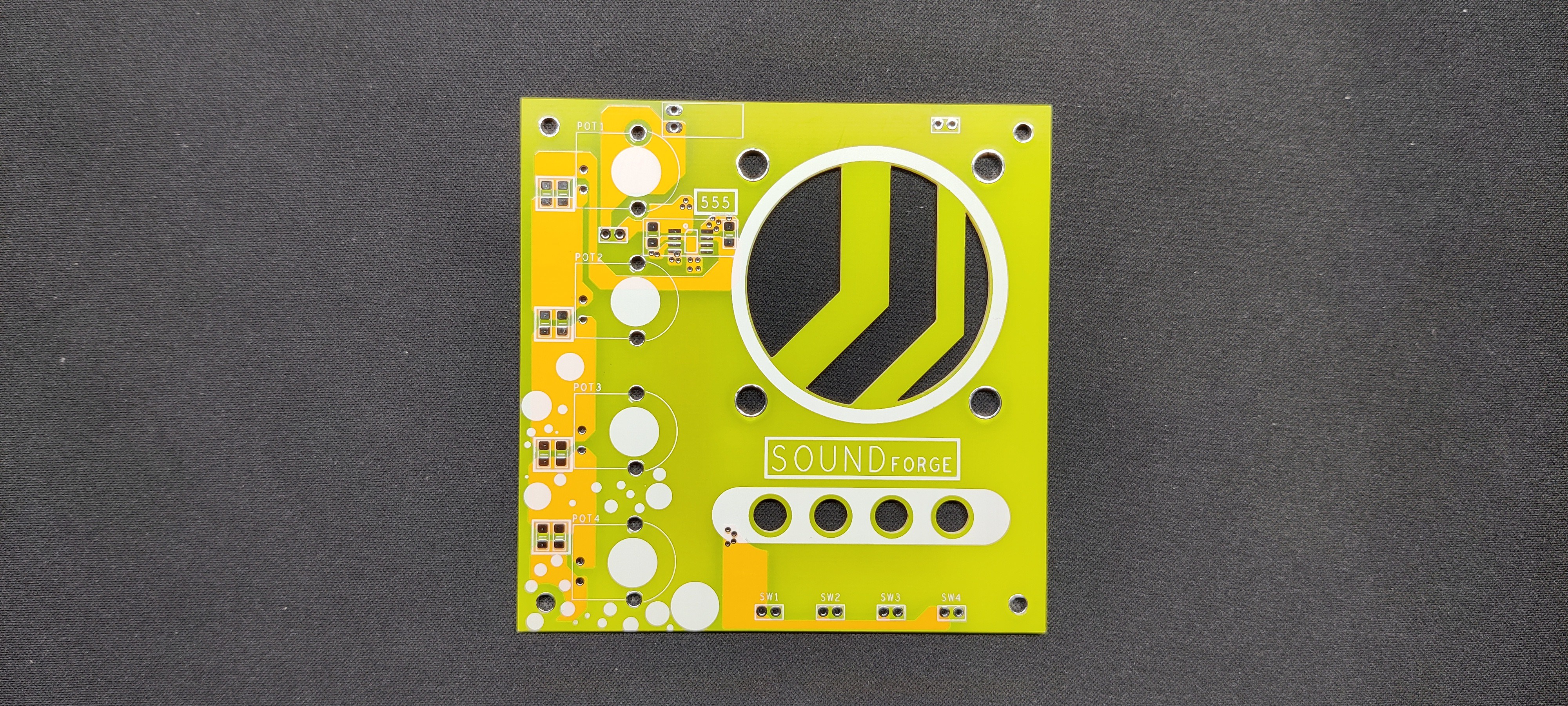

We designed the 95 mm by 95 mm PCB, and after that, we arranged every component on the PCB so that it looked good. We put a speaker on the right, potentiometers arranged vertically on the left, and a switch positioned horizontally on the bottom.

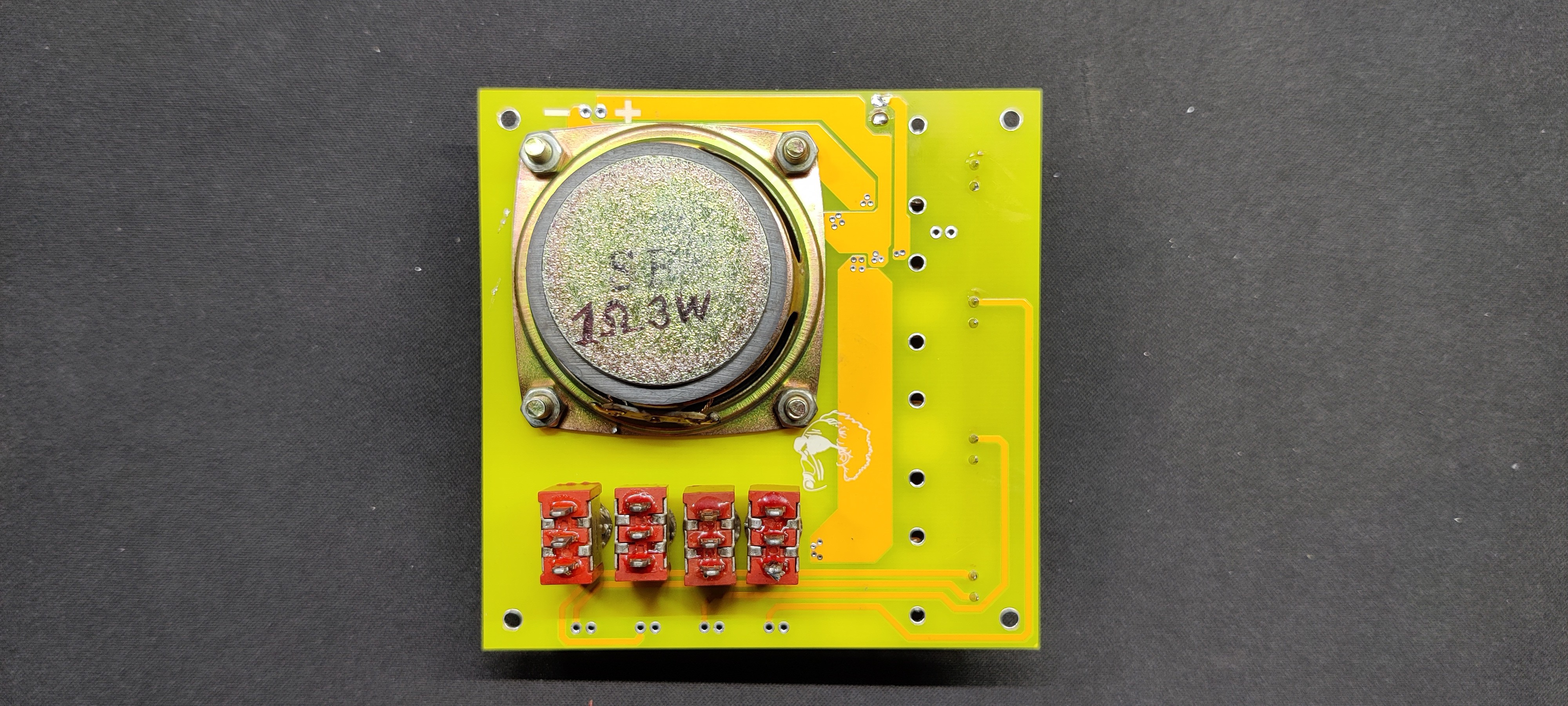

Just the potentiometers were positioned on the top side; the speaker and lever switch were positioned on the bottom side.

Also, we added grills and mounting holes for the speaker on the PCB.

We started with a simple PCB model and then created an enclosure to house the PCB and protect all of the electronics within.

White PLA was used to 3D print the enclosure, with a 0.6mm nozzle, 0.2mm layer height, and 20% infill.

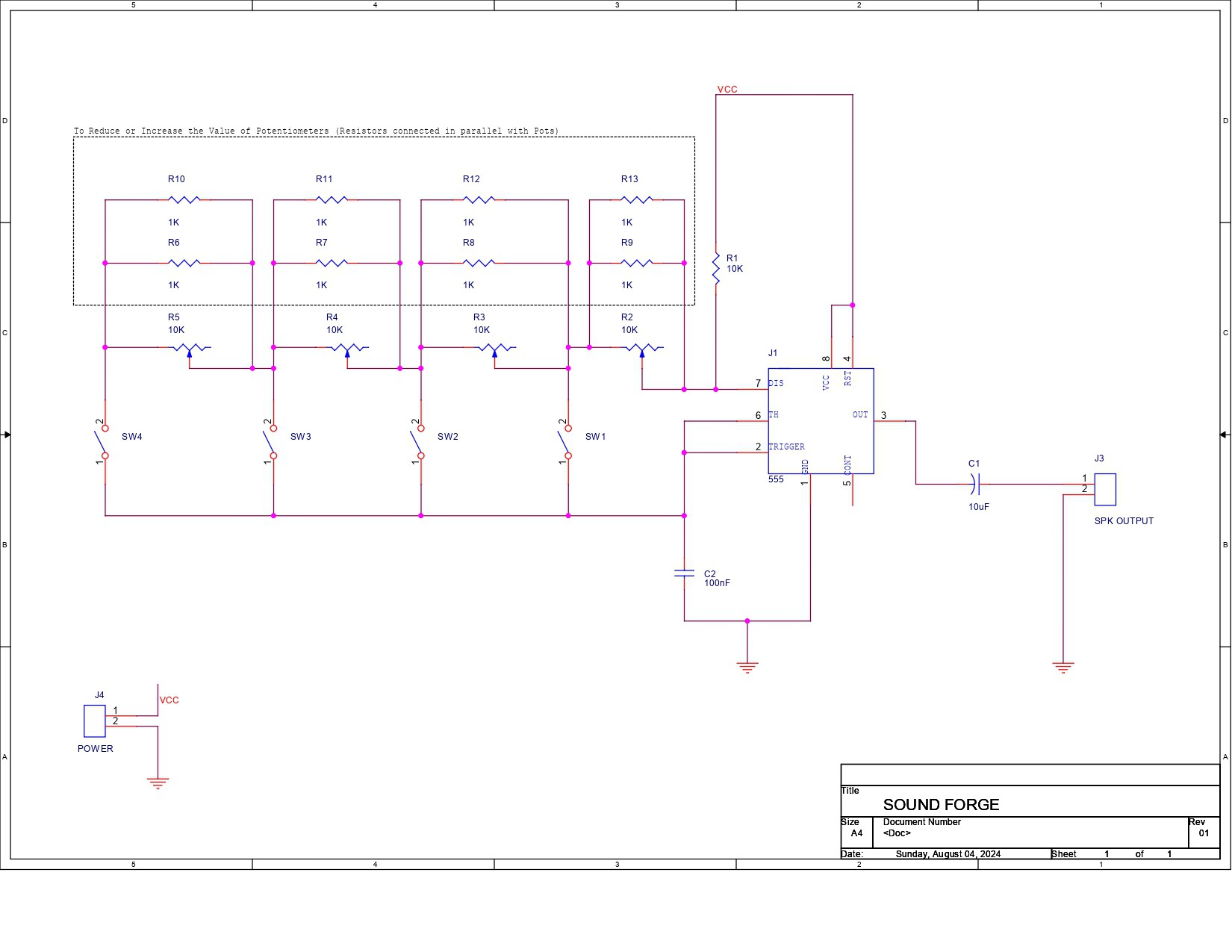

Circuit

The circuit, which had a single 555-timer IC connected in monostable mode, was prepared next.

Here, we utilized a schematic of a 555 Mouth Organ Piano, which is rather popular, and we have created our own using its fundamental design. We added a potentiometer in place of the resistor and a lever switch in place of the tactile push buttons to modify the original schematic.

The sound generated by pressing the button in the original diagram was determined by the value of the resistor that was connected in series with the button. This resistor was replaced with a potentiometer, allowing us to adjust the resistor's value and thus modify the sound.

The speaker's negative is connected to GND, and a 10 uF capacitor was added to the output in series with the speaker's positive.

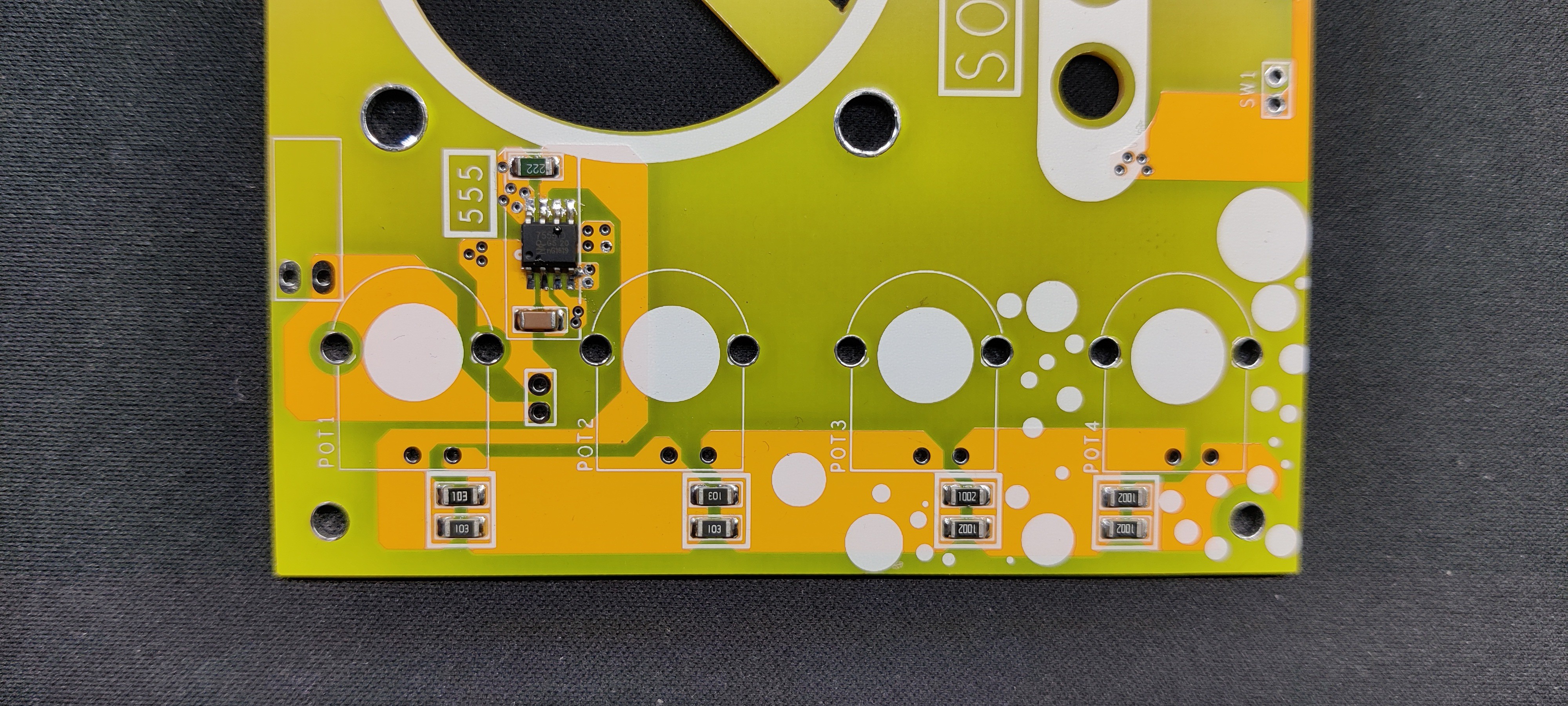

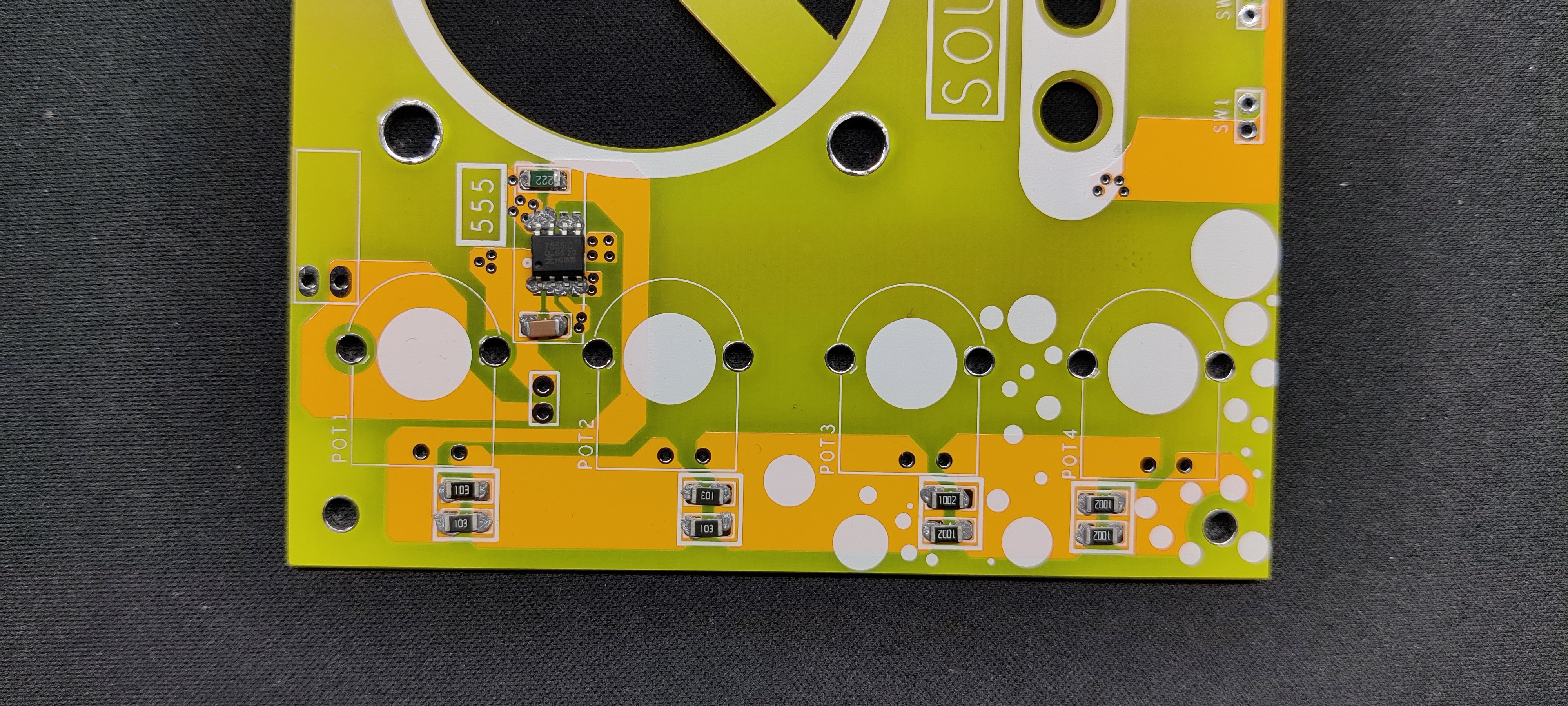

Regarding the board outline, we created the PCB for this project using the dimensions provided in the Cad file.

HQ NextPCB

After completing the PCB design, we export the Gerber data and send it to HQ NextPCB for samples.

We placed an order for a white silkscreen LED board.

After placing the order, the PCBs were received within a week, and the PCB quality was pretty great.

HQ NextPCB and HQ Online are the overseas trading brands of Shenzhen Huaqiu Electronics Co. Ltd.. Huaqiu has served national engineers for over 15 years, becoming a household name for providing full-feature multilayer PCBs engineers can trust.

NextPCB brings these capabilities, speed, affordability, and more, to international customers, skipping the middleman and providing the same intelligent online quotation system from the industry’s experts.

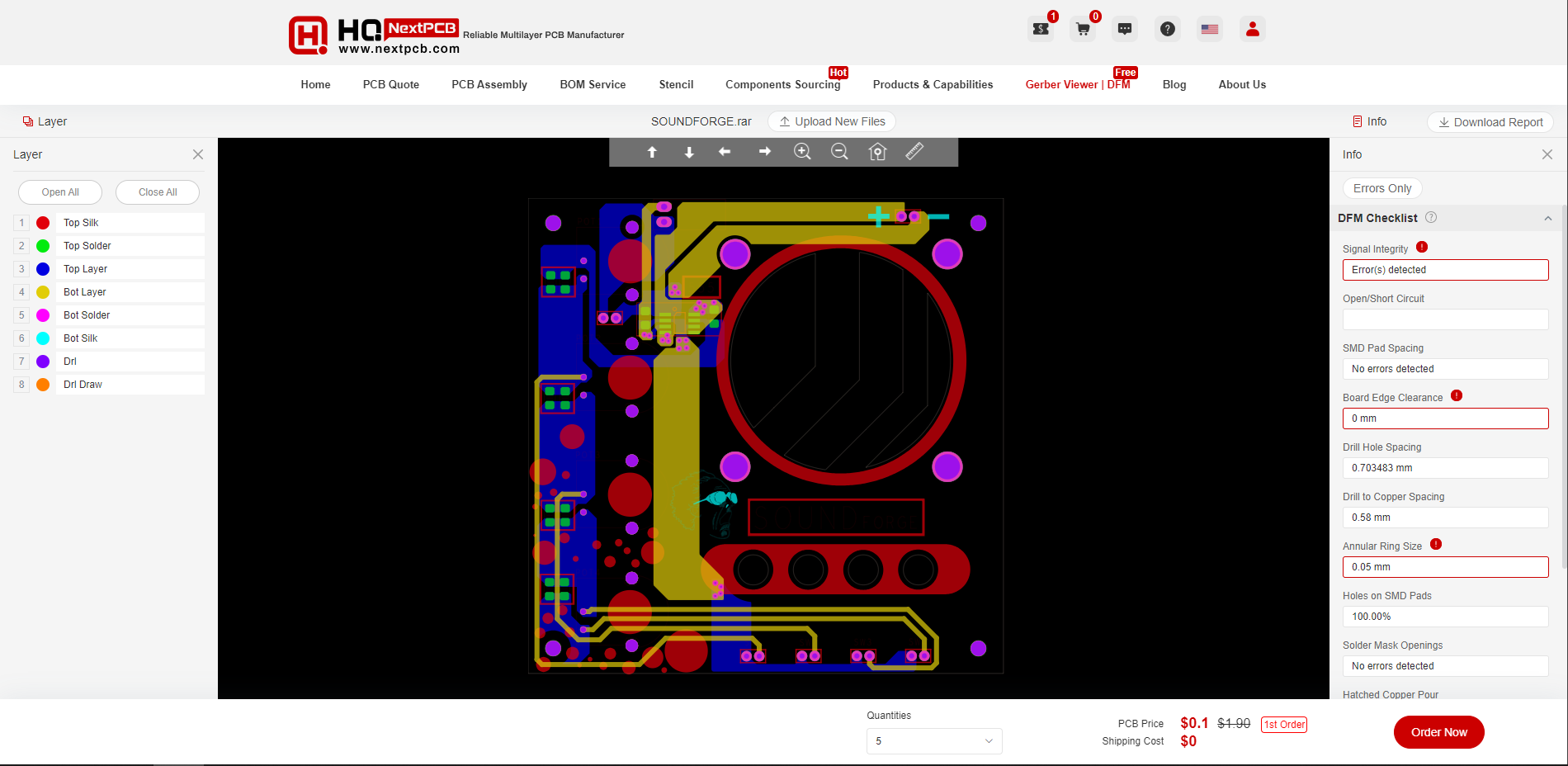

Huaqiu Electronics believes innovation is key to maintaining excellence, which has motivated them to transform the electronics manufacturing industry. Huaqiu’s in-house engineers developed the free Design for Manufacturing software, HQDFM, revolutionizing how PCB designers visualize and verify their designs.

HQDFM: Free Online Gerber Viewer and DFM Analysis Tool

Also, NextPCB has its own Gerber Viewer and DFM analysis software.

Your designs are improved by their HQDFM software (DFM) services. Since I find it annoying to have to wait around for DFM reports from manufacturers, HQDFM is the most efficient method for performing a pre-event self-check.

https://www.nextpcb.com/free-online-gerber-viewer.html

With comprehensive Design for Manufacture (DFM) analysis features, HQDFM Gerber Viewer is a free, sophisticated online PCB Gerber file viewer.

Along with supporting the top 5 web browsers, it is compatible with RS-274x and Extended (X2) Gerber files as well as OBD++ files from popular PCB CAD programs including Autodesk Eagle, DipTrace, DesignSpark, Altium Designer, and KiCad. HQDFM is a product of HQ Electronics, which also developed HQ NextPCB and HQ Online.

It provides insights into advanced manufacturing by utilizing over 15 years of industry expertise.

You guys can check out HQ NextPCB if you want great PCB service at an affordable rate.

Arnov Sharma

Arnov Sharma