Choosing the microcontoller

When I was planing the entire project I also decided to make it more

challenging and interesting to me. And because of that chose a bit

unusual MCU for this watches. My pick stick to ATtiny85 - I beleived

that it would be an interesting challenge to make watch on this MC, but

later I had to switch to ATtiny85 and I will describe why so. Most basic

MC for such project would be ATmega328, which is used in Arduino UNO,

but again, it was not interesting enough to me and the solution on this

MC is already exist on the net.

Another reason why I’ve chosen AVR MCU but not ARM (STM32) or other is

because I’ve already had enough knowledge and skills about programming

such MCUs.

So, as you probably know, ATtiny85 has not a lot of pins, actually there

are only 5 pins which I could use to run an entire watch! It means that

I had to design various drivers and multiplexers to drive all the

devices with which ATtiny communicates.

Display driver

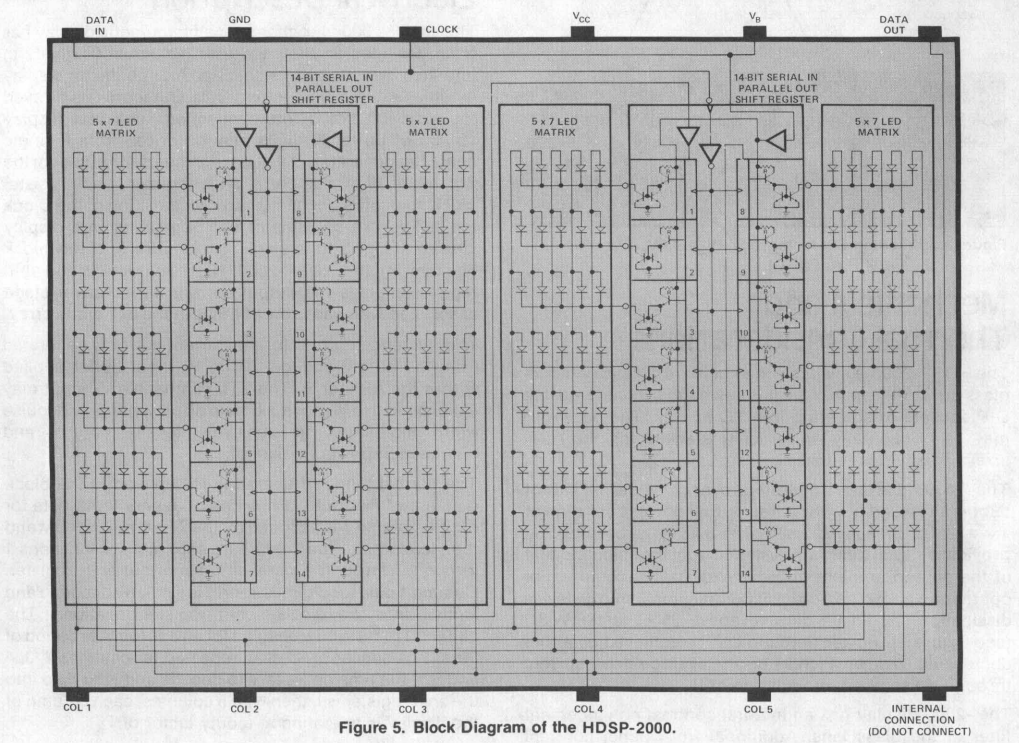

The key devices which are driven by MCU are of course indicators

HDSP-2000, without them entire project has no any sense. Due to the lack

of available pins in MCU, display driver should receive data from a

small amount of pins. If we look closer at the indicator, we’ll see that

it is basically a shift register which receives data through SPI bus. It

can be inferred, that the most vital signals for indicator are serial

clock and serial data signals. All other signals can be generated from

clock and data signals and I will explain how.

First of all, let’s have a look at columns signals. Each time a high

voltage level is applied to one of these pins the corresponding columns

in LED matrix are driven and the LEDs in this column emit light. It

means that after the new values have been stored to the shift registers

the next column should be driven. Basically, it is very similar to the

“running leds” projects, which can be easily built on decimal counters

like CD4017. Each time a new data is stored to the shift registers of

indicators, the counter CD4017 will count to the next value and the

corresponding output pin will drive the column of indicator. Schematic

of indicator is shown on fig. 1.

Figure 1. - HDSP-2000 indicator schematic

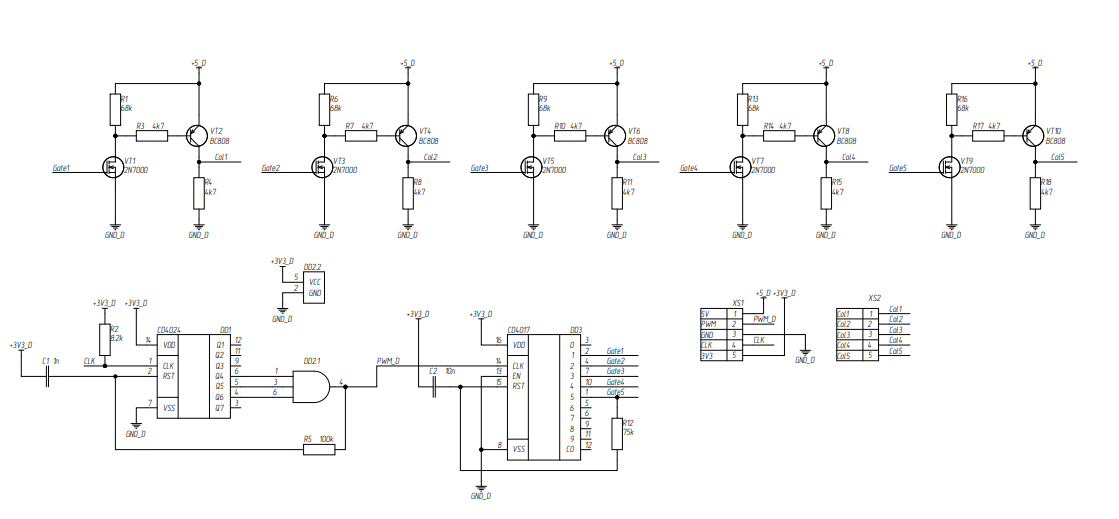

Another problem is to get know when the transition of data to shift

registers is finished. This issue also can be solved with counters. By

counting the number of bits, which were transferred, it can be checked

whether or not the process is finished. In HDSP-2000 there are four

shift registers and each of them stores 7 bits, so the total data

capacity of indicator is 28 bits. Since two indicators are used in this

project, the capacity of display block is twice bigger, which is 56

bits. The amount of bits which were sent to the display can be obtained

from serial clock signal – each positive front of clock represents a one

bit of data that has been stored to the indicator. To count bits a

binary 7-stage counter CD4024 was used. The binary representation of

decimal number 56 is 111000, so the corresponding pins Q3, Q4, and Q5

are high when counter reach value 56. Early mentioned pins are tied to

single AND gate with 3 inputs. Output signal of AND gate is used as

clock signal for decimal counter CD4017. Drivers schematic is shown on

fig. 2.

Figure 2. - Display driver schematic

Since indicator HDSP-2000 has

only 5 columns counter CD4017 counts only from value 1 to 5. When

counter reaches value 5, corresponding pin “5” changes its state from

low to high and through RC low-pass filter sets high level on signal RST

while simultaneously driving fifth column of indicator. When high level

is set on RST pin of counter it resets its value. RC low-pass filter is

needed to create a time delay, so the fifth column could be driven for

some consistent time. The same solution was used to the output of AND

gate in order make sure that positive clock front for decimal counter

CD4017 would not disappear instantly after binary counter CD4024 resets.

The signal from AND gate is also used...

Vitalii

Vitalii

Thanks for the open source, how do I choose the value of component L1 in supply_core?