The FIRST Robotics Competition is a high school engineering program that utilizes both commercial off the shelf (COTS) components and custom components designed and manufactured by students. The Kit of Parts (KoP) is provided to all teams as a starting point for their design as a part of their seasonal registration fee. Built off a simple skid steer drivetrain that was originally designed nearly 20 years ago, the KoP (shown below) lacks the maneuverability that has become the competitive standard. Off-the-shelf “swerve modules” allow for rapid omnidirectional movement but are expensive and difficult to assemble, calibrate, program, and maintain. This makes it unattainable for many underprivileged teams with less funding, fewer mentors, or time to build, program, and test their robots. The COTS swerve modules (shown below) that are currently on the market are too expensive and complex to be scaled up to inclusion in the KoP.

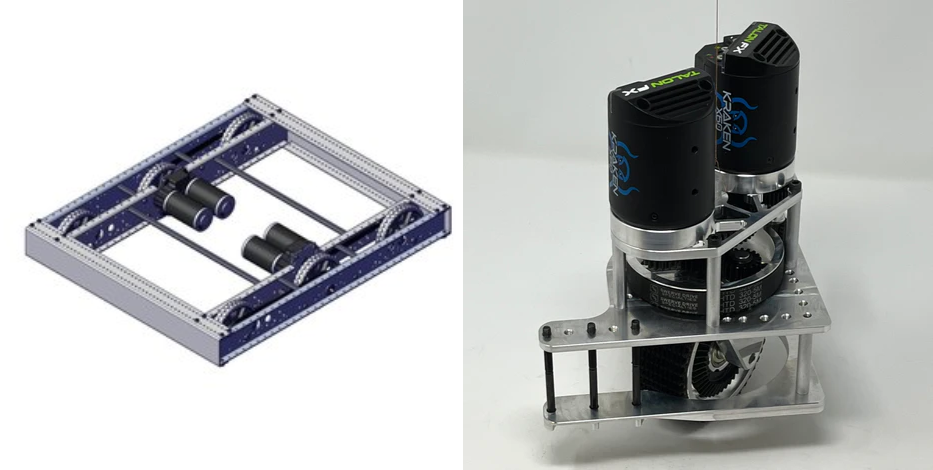

Figure 1: Current Kop AM14U5 Drivetrain vs Expensive COTS Swerve Module

Our goal is to solve this problem by proposing a new KoP drivetrain, focused on a new “swerve module” design, allowing for the speed and maneuverability available to top teams. Some constraints come from the current FIRST rules set for robot construction, like electrical specifications: 12V 18Ah SLA battery with a peak current draw limit, REV Robotics Power Distribution Hub with 40A breakers, and a required NI roboRIO robot controller with a specified baud rate and communication protocol. In order to meet the design objective, the purchase cost should be roughly equivalent to the current KoP drivetrain (~$1000), but at least significantly lower in cost than COTS swerve drivetrains (~$2500). A solution to this problem requires a detailed BOM outlining the cost as well as assembly steps that allow students to build and operate their drivetrain with comparable resources and time as the current KoP drivetrain (approximately one full day with a few students). These will be included as deliverables along with a functional physical prototype drivetrain and sample control code. The focus has been set on the Swerve Module as making swerve accessible to all teams in the program will raise the floor and enable all teams to have a better experience when competing.

During the time that we spend coming up with solutions to the problem, we expect some obstacles, including selecting appropriate motors and minimizing the volume that the module takes up. Most problems that we encounter will be solved through iterative design. Benchmarking the current options available, including the current KoP drivetrain as well as the most common COTS Swerve drive train, will be critical in helping define the problem as these benchmarks will inform the specifications for the solution.

THowden-Capstone

THowden-Capstone

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.