With all components fully assembled—the arm, watertank, valves, and electronics—we were ready to integrate everything:

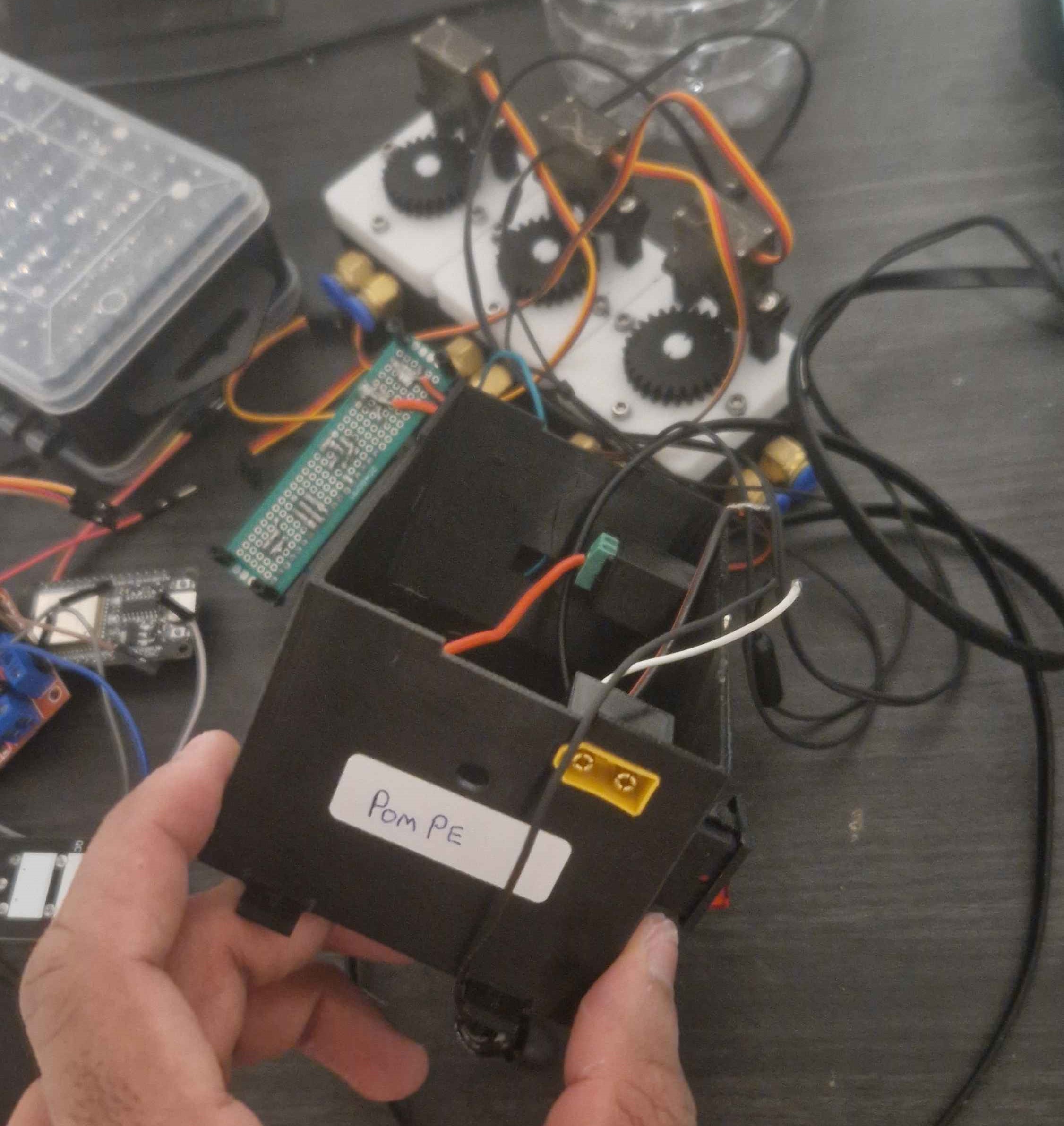

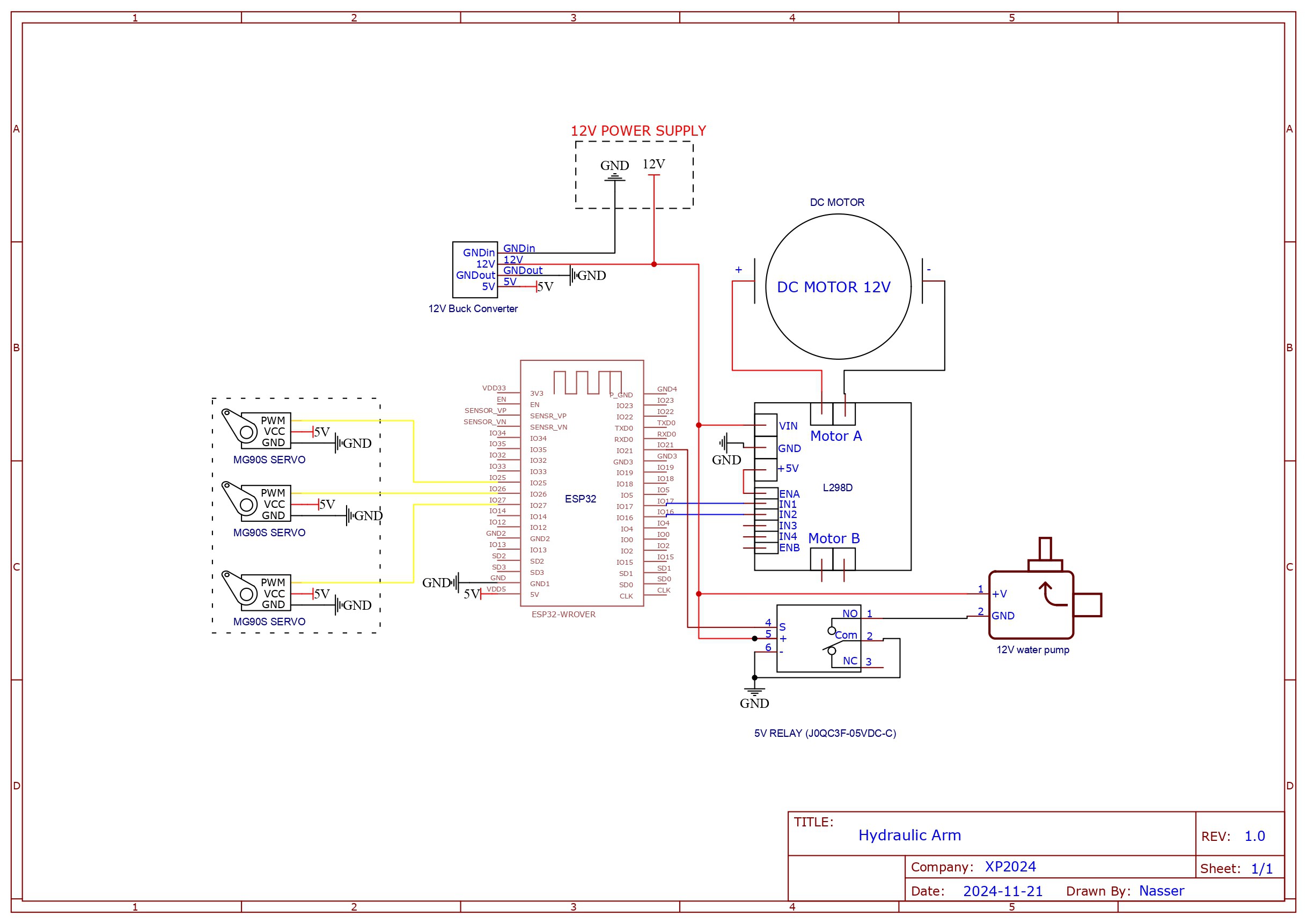

- Electronics Box: We wired the valve, pump, and rotation motor to our electronics box.

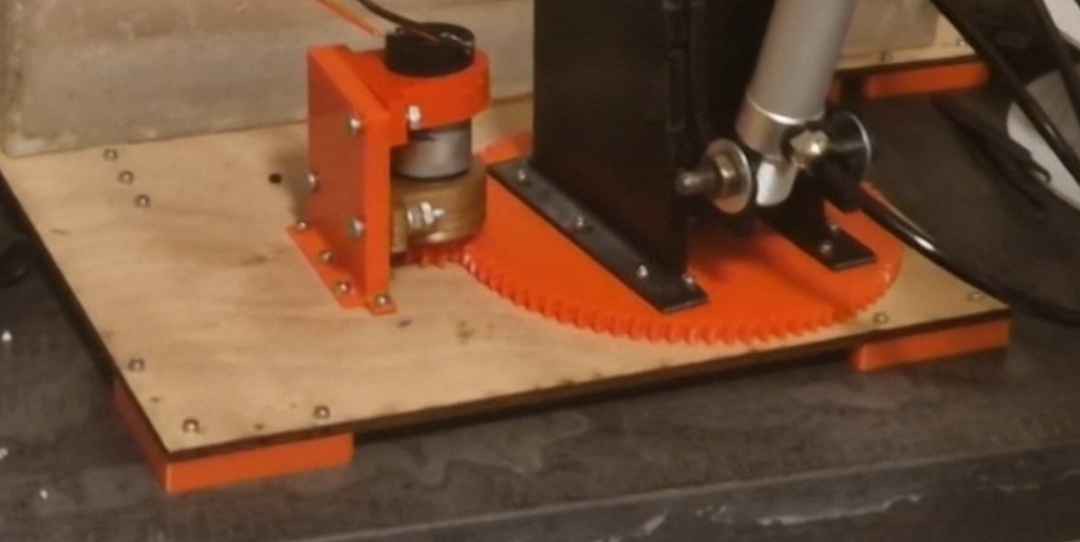

- Base and Gear Mounting: The large gear, arm, and rotation motor were securely bolted onto the wooden base.

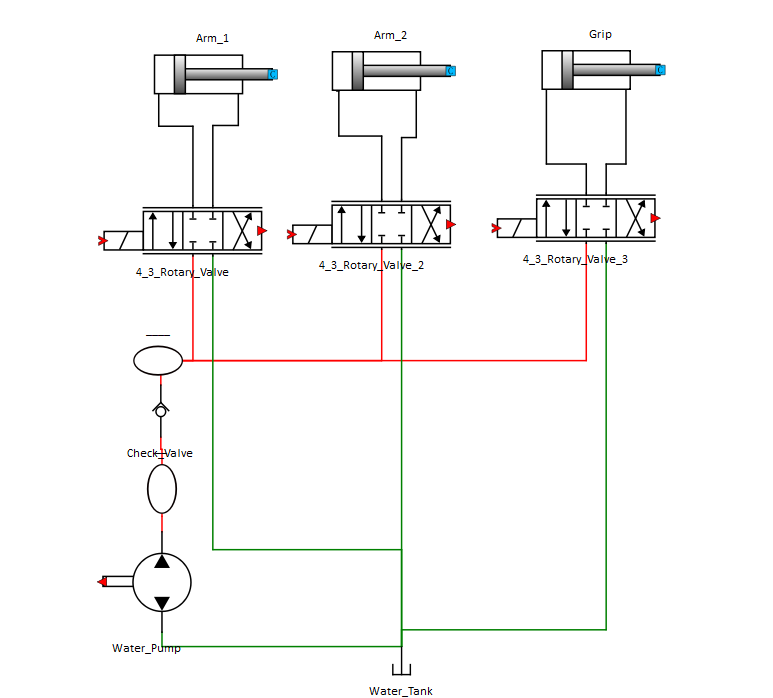

- Hydraulic Tubing: All hydraulic tubes were connected,.

- System Filled and Ready: We filled the hydraulic tank with fluid, checked for leaks, and ensured all connections were secure.

Finally, everything was ready for the first test run!

Nasser

Nasser

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.