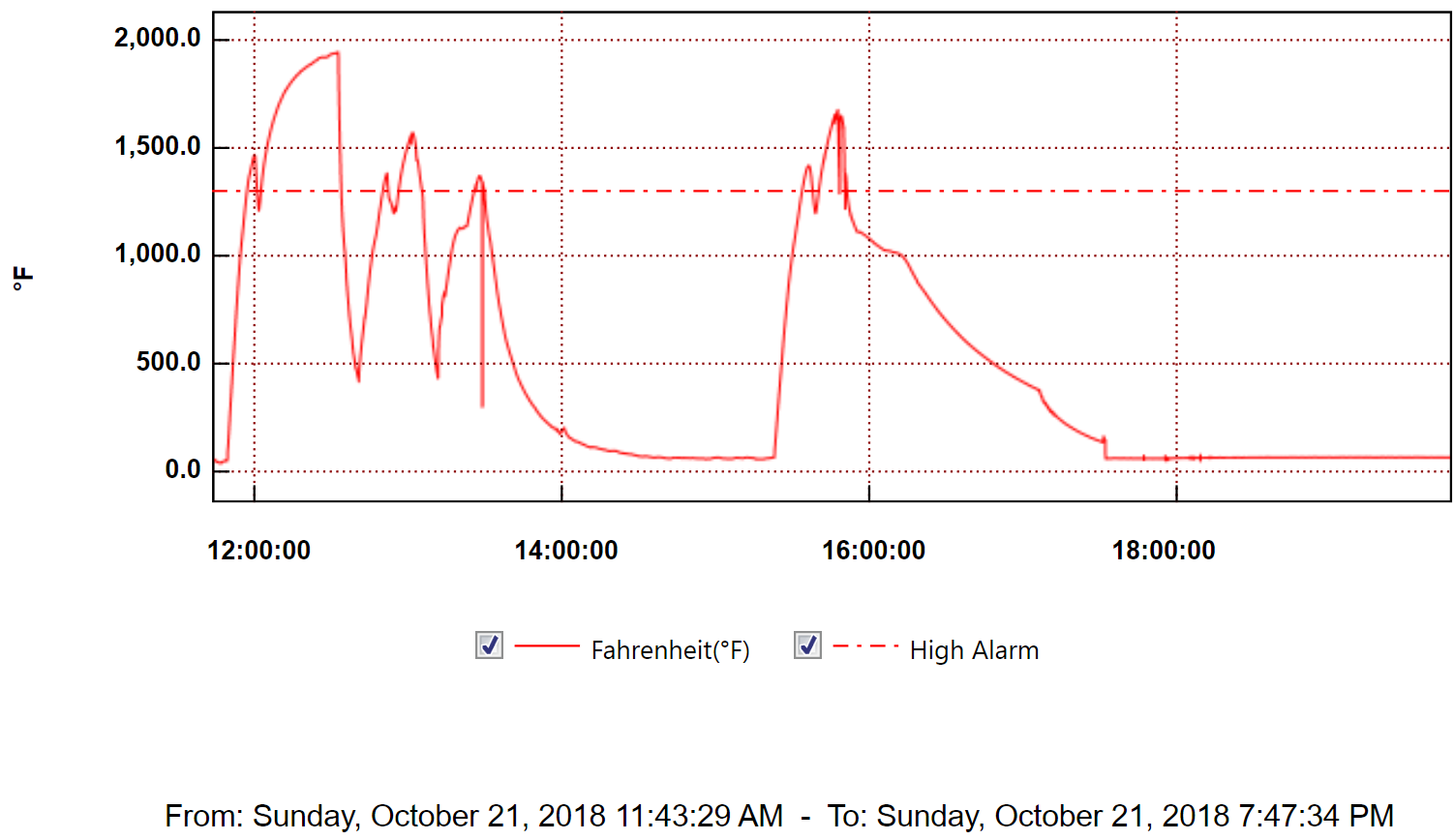

I have some mixed news from my attempt this weekend. I got all the data, but the act of observing the temperature and filming combined with more trouble from my regulator caused a decline in casting quality. I suspect it mostly came down to metal that got too hot, thus absorbing more gas from the atmosphere. I also had to move the camera and take laser temp readings, so I didn't remove the mold from the kiln as quickly as last time, and didn't pour as quickly.

First three attempts on the graph was me messing with camera and lights to try and raise "production values" so I left the crucible in the kiln for too long. The last attempt the crucible was in the kiln for about the right amount of time, but the kiln was over-fed by propane.

This week I am sick, so next week I will retry all of this and hopefully have some video worth publishing. I took some time to setup lights, and the video quality was significantly better - next time I will already have that experience so I can setup lighting quickly and before doing anything important to the casting process.

Val

Val

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.