This weekend I finally completed fixtures to increase the casting quality. After refractory which cracked and fell apart, clay which exploded in the kiln, CeramaCast which fell apart despite the high price, and finally a cost-inefficient CNC quote, I iterated onto something that works.

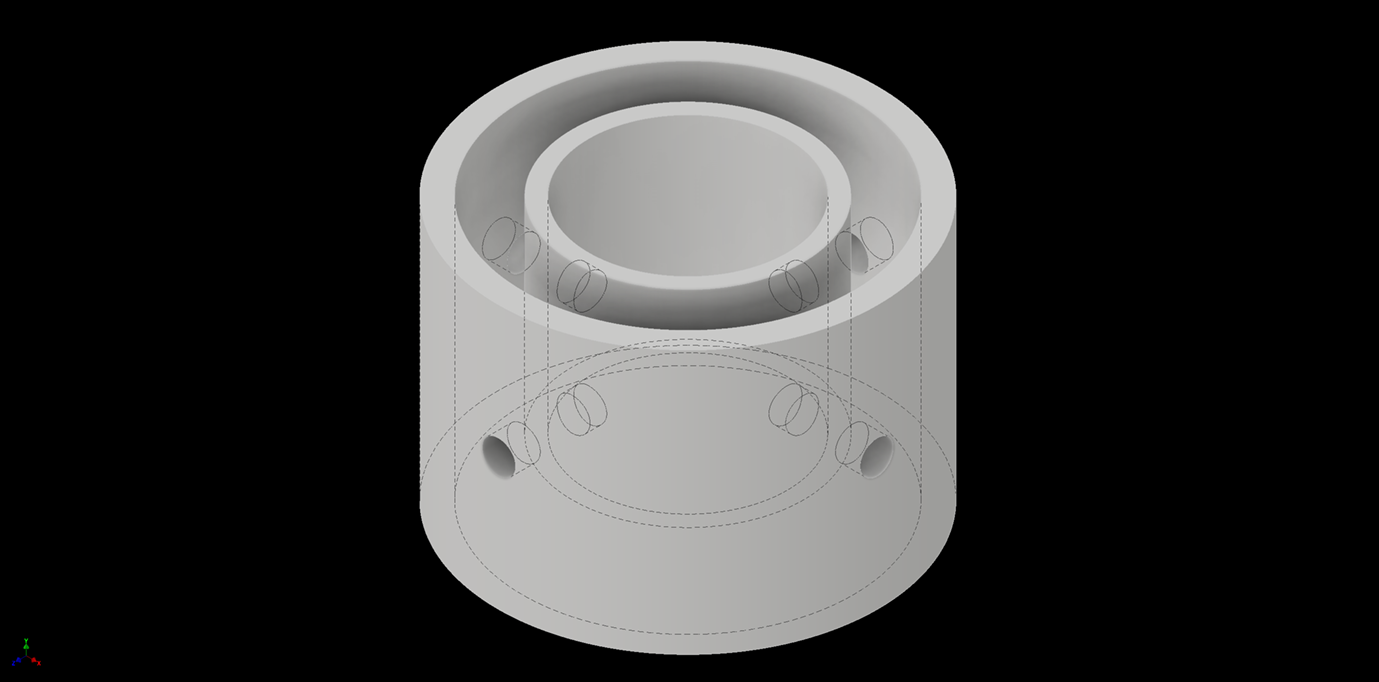

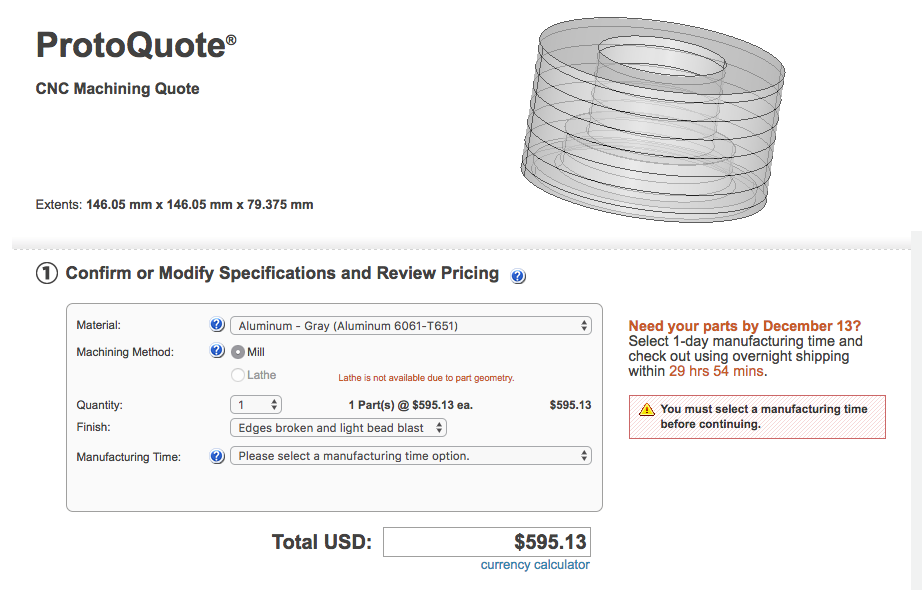

I estimated the CAD model used for the CNC quote with steel pipes of diameters stocked by the nearest steel yard - features like bevels, tapers and 1-piece construction had to be given up but the resulting cost was around $90, down from $900 from the CNC process.

The inner pipe sized to accept the riser is held inside the outer pipe that connects to vacuum flask lip with 1/2" screws. The holes took two weekends to drill and tap, but the result is holding well. The cavity between the pipes is filled with refractory. which no longer needs to hold together by itself.

The original model quote (it would be two of those):

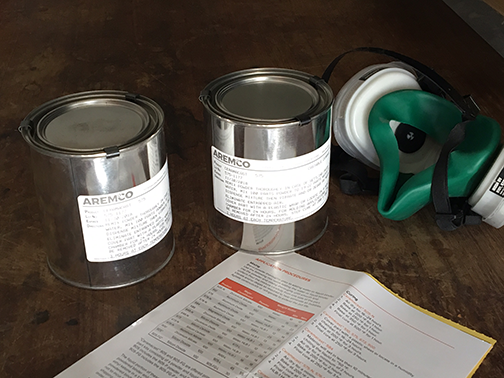

Ceramacast.

Caramacast after hardening. Those broken pieces are worth $300, pretty unpleasant.

Val

Val

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.