The second pass PCBs arrived around 2024-12-01. Another very long wait for OSH Park product. I desoldered all of the major active components from the first pass PCB and soldered them onto the rev2 PCBs without issue. The new big PFET and TVS diode were added along with all of the new passive components. There were no shorts between the leads of the SSOP digital parts -- amazing.

I plugged in the hand piece with an 18AWG nichrome tip and connected the power supply set to 6VDC/6.4A. I cranked the current setting to cause 6A from the power supply and began taking temperature measurement around the PCB. The only temps that I was interested in were the two FETs and the sense resistors. All of them settled to around 40C (ambient = 14C). This was less than what I was expecting, but welcome. No heat sinks required!

When I swapped the 18AWG tip for a 20AWG tip the supply current increased to 6.4A, which is above the rating of the AC/DC converter that I bought. The tip was glowing a brilliant red though. I thought about reducing the current setting to allow a max of 6A from the supply when using a 20AWG tip, but then I wouldn't get enough current to drive the thicker 18AWG tip to the proper temperature ( I need about 20A through the tip for that.)

Back to the Drawing Board

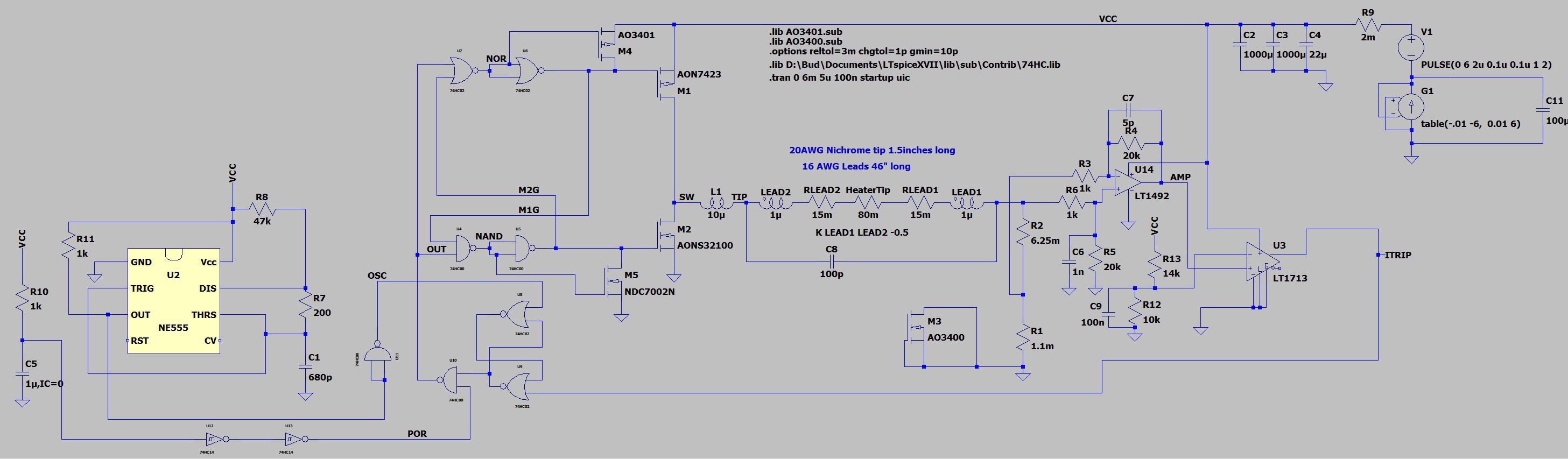

My first thought was to limit the average voltage at the tip. This could be done by adding another opamp to sense the tip voltage and reduce the current when a voltage limit was exceeded. This would require another PCB pass...ugh. I implemented this concept on LTSpice with promising results. But during the analysis of this approach I had a different thought: why not just let the power supply drop in voltage when the current exceeds 6A? I implemented this in LTSpice using a GM source as shown below:

The power supply now is a 6A constant current source when the load exceeds 6A. This seems to work well. When the system attempts to sink more than 6A of current from the supply it drops its voltage, keeping the current constant. Since the current set point is dependent upon the supply voltage, it decreases with decreasing supply voltage. If the tip is 80mR and the circuit tries to sink 6A the supply voltage falls to around 4.75V while delivering 6A. This is nearly a perfect solution to the problem.

Different in Practice

I adjusted the current set point to 2.4V with a supply voltage equal to 6V, which is a peak output current = 19.2A. I then measured the supply voltage (using the 6VDC/6A AC/DC adapter as the power supply) while changing the tips from 16AWG to 20AWG. The supply held steady at 6V, while both tips glowed a nice cherry red. I'm pretty sure that the current drawn from the supply when using the 20AWG tip exceeded 6A, but the adapter voltage did not droop.

So I have a small dilemma: Should I just leave the circuit as is and hope that the adapter can handle the extra power dissipation without any problems, or should I change the adapter circuit to lower the current limit threshold to 6A? I chose the former. If the adapter fails due to excessive current or power dissipation then I'll have to purchase another one and try to alter the circuit to lower the current limit. Until then...no harm, no foul.

Bud Bennett

Bud Bennett

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.