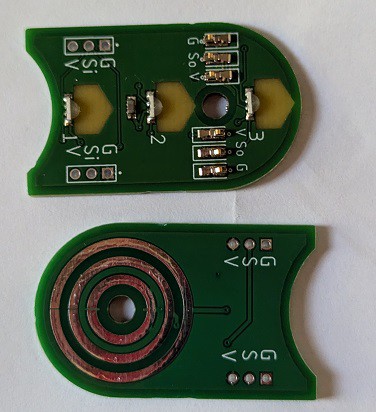

Once the components were attached to the boards, the two layers of boards had to be sandwiched together with the spring contacts pressing against the circular solder pads.

A push rivet goes through the corresponding holes in the two layers to align them and allow them to pivot. The push rivet needs to be the correct height to hold the layers against each other firmly so they don't separate, but aren't too close either. A buffer layer sits in the middle of the opposing PCBs so that the spring contacts aren't crushed. The working height of the spring contacts is about 1.8 mm, so I used 1.6mm laser cut acrylic to create a buffer layer in a shape that doesn't overlap the components. In addition, male header pins hold opposing components together, so I needed to find male header pins with an insulation layer no more than 1.6 mm thick. I found these at DIgiKey.

debraansell

debraansell

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.