0100:

Assembly is going really slow. I'm ... drained.

The acrylic has been designed and I uploaded a photo of a prototype. Progress was made after the prototype and the final acrylic looks much better, diffuses more light forward, fits tight with just enough tolerance.

Did a quick test of current in the nametag mode with the brightest RGB program (rainbow) running.

20mA with no screen. Add the screen, is 27mA.

I didn't test with no RGB program but I would guess between the quiescent of the RGBLED controller and MCUs, the current would be something like 10-12mA. Not awful I guess. This is with only basic consideration for power optimization, and soft SPI master on the main MCU.

I'll stop procrastinating and get back to assembly in a little bit.

2030: Still soldering. Still adding headers and standoff pins.

How is it done?

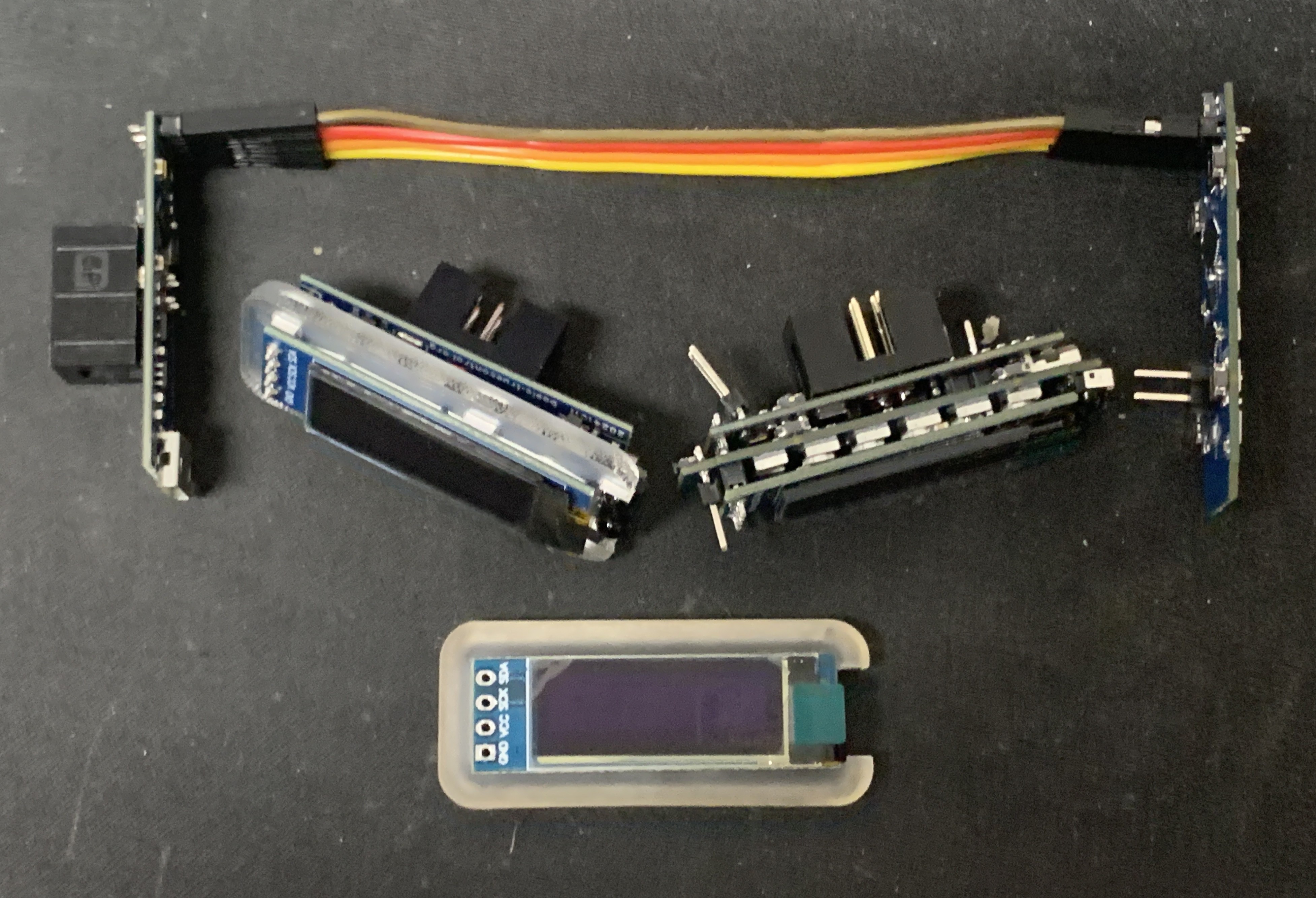

I have jigs for the top and bottom boards. The top board gets two pin TH header.

Bottom PCB gets modified addon connectors. These are modified as I screwed up the board and have the connector mirrored, lol. Don’t want to pass power back over the GPIO and cause problems. The header gets soldered and bodge wires added.

Following these steps, the OLED gets attached to the top board next with acrylic and tape sandwiched in between. After that, the OLED+acrylic+top assembly gets soldered to the bottom assembly, finishing the process.

Note that if this was to somehow win a spot in the contest, parts of this assembly would be simplified or replaced with SMT alternatives in order to speed assembly and reduce hands on work needed.

I hope to be at the OLED assembly phase in a few hours. If things go well I may have them all assembled before I go to sleep.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.