-

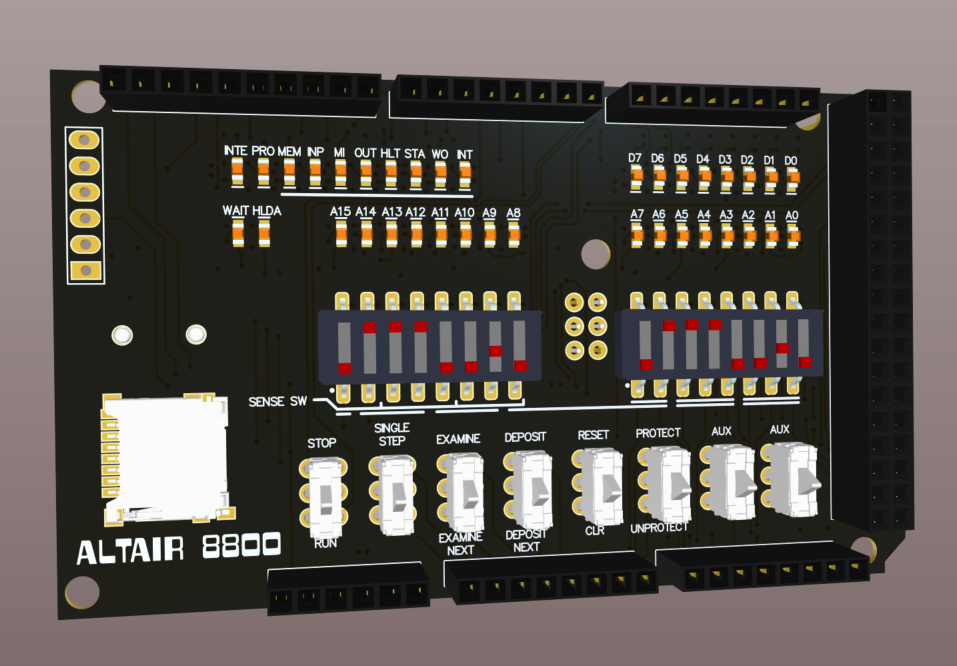

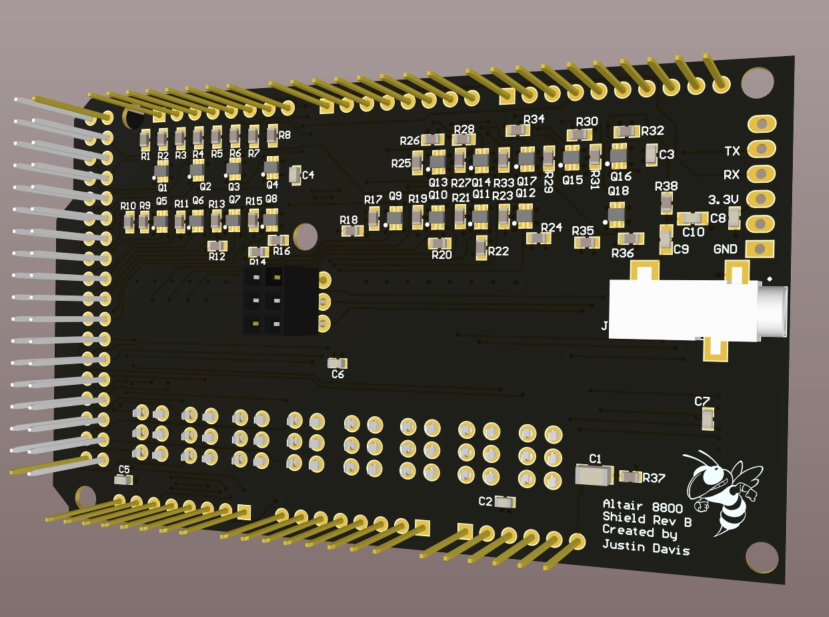

Rev B

12/20/2019 at 14:17 • 0 commentsThis project has been sitting on the back burner for a loong time now. Now that I have small window of free time, I figure I'd come back around to it and do the rev B board. I had a couple errors in the layout for the first version. I changed the SD card interface so it's a pass-through - I don't see a way around it so there will be a few pins visible on the top side.

I also decided to make a few other changes. I wanted the top of the board to look a little cleaner, so I moved all the passives to the bottom of the board. I also figured I'd implement the music output too. It's just two caps, a resistor, and a 3.5mm barrel receptacle. There's room for it on the bottom of the board where it will be hidden.

-

PCB prototyping

03/16/2017 at 13:23 • 1 commentI've gotten some comments about rapid-prototyping PCB fabricators. I know there's a lot out there, but one site I use to get quick quotes from a lot of places is http://pcbshopper.com/

You put your board requirement in such as size, mask color, etc. and it spits out many of the rapid prototype places like PCBWay, OSHPark, Dirty PCBs, EasyEDA, Bay Area Circuits, etc with a price which includes total boards cost, per board cost, and includes shipping costs. So you can see how much you will pay at each place with shipping. However, I often end up using PCBWay since their prices are often the best and give lots of free options such as board color. Since I wanted a black soldermask, they usually don't charge more for black soldermask.

Each place has different bonuses like low shipping costs, or special mask colors, etc. so it's good to check each line. Some places have price cutoffs for board size like 5x5cm, 10x10cm in their pricing, and others have a rate for the exact board size. However, they all have a minimum board number of 3 or 5, so if you only plan on making one board, your board cost is really much higher.

But it's great how low the prices are for making PCBs these days. I remember the story of Steve Jobs selling his VW van to pay for the first run of Apple 1 boards. These days it's so much cheaper.

Once I create the rev B boards, I will upload them to wherever people would like. Some site do a good job of letting others order your boards, so you don't have to worry about getting them boards. But you still have to order 3 of them at minimum. It would be nicer if you could order 1 board, and then when 2 other people order that same board, it triggers the board getting made. Or if more people order in a certain window, then it might bring the board cost down.

-

Blogged

03/15/2017 at 15:27 • 0 commentsFirst, got my project on the front page of Hackaday which I thought was very cool. Thanks to everyone for the encouragement!

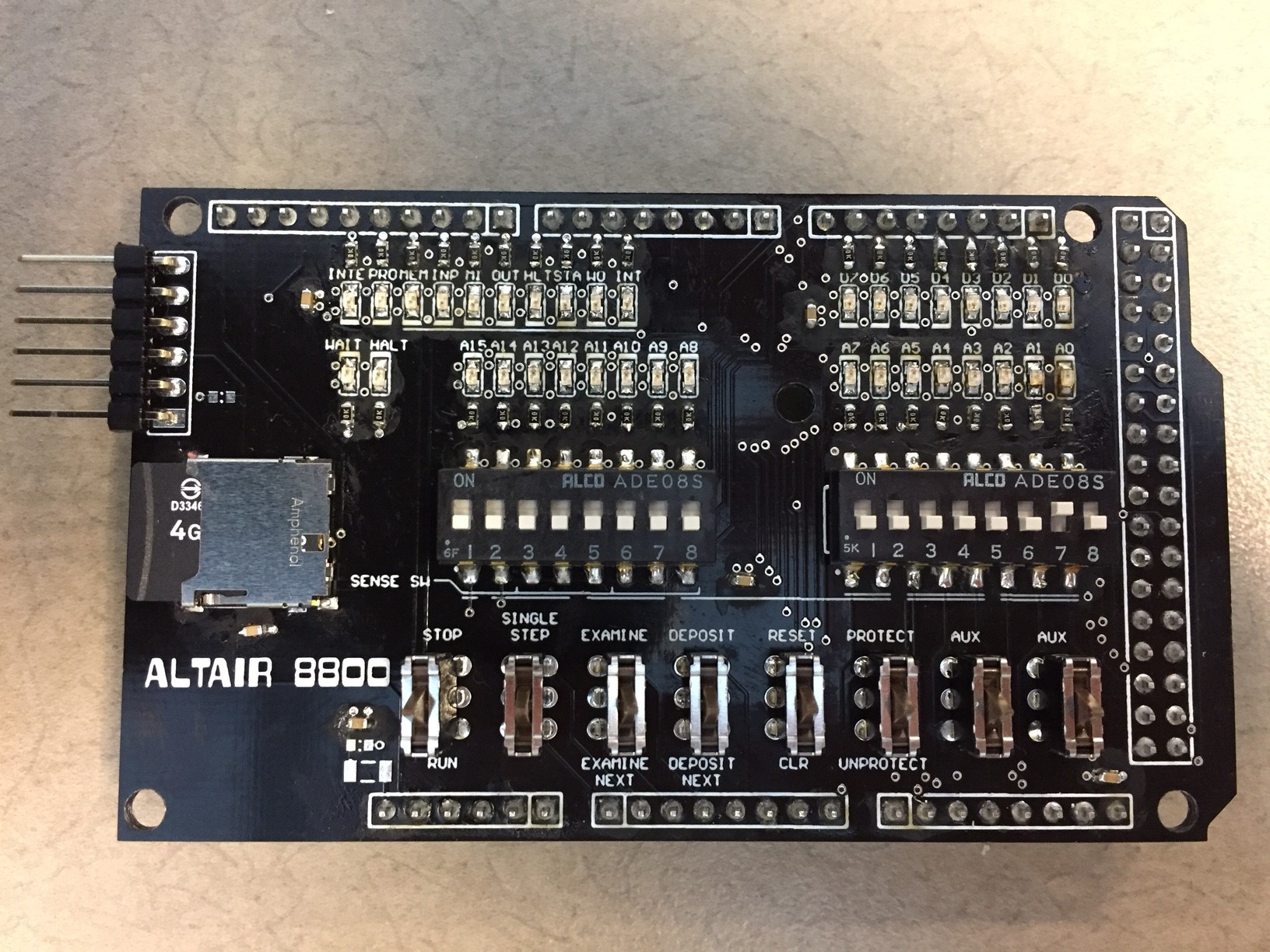

Second, I figured I'd better check out the rest of my board. I soldered on the microSD card receptacle and the Bluetooth comm headers. So I have a photo of the finished version of the top-side with the microSD card installed.

Then I flipped the board over to solder on the SPI connector. And that's when I realized I made another mistake. The pitch on the connector is only 50mils. I'm not sure how I made that mistake, but I think the only fix for this is messy. I only need to connect 3 pins on that header, so I may try to hack on three individual posts. I knew I took a risk by going with a surface mount header. I also chose one which did not have alignment posts, so I knew alignment could have been a problem. I think I may go back to a through-hole header for rev B. I went away from it mostly for aesthetics (there would be a 6-pin connector between my switches). I'm not sure if I will ever make a second run of boards just because of the cost, but if enough people are interested, then I will. I should order a bluetooth module to check out that header too before I make a rev B.

-

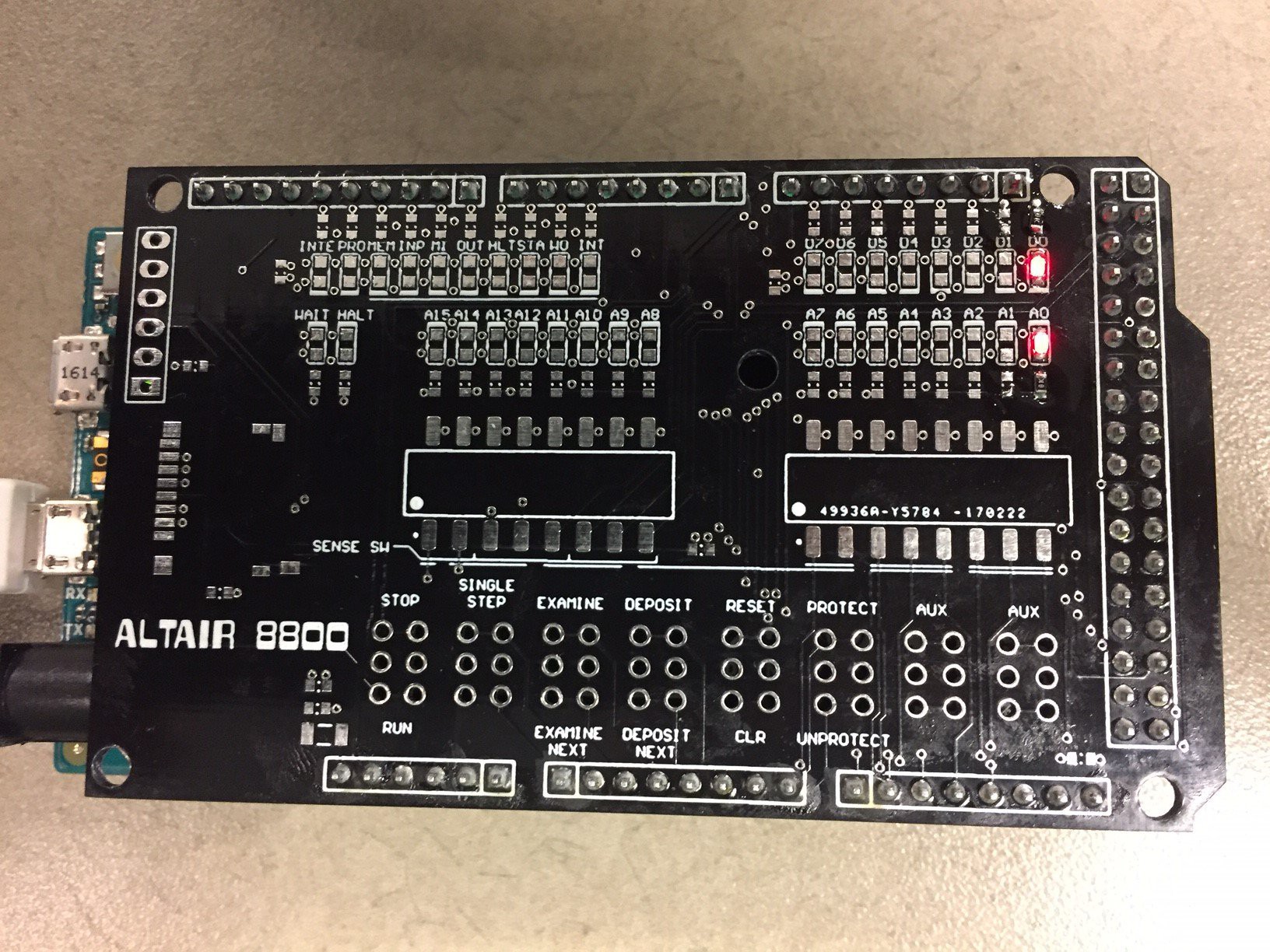

Primary objectives complete

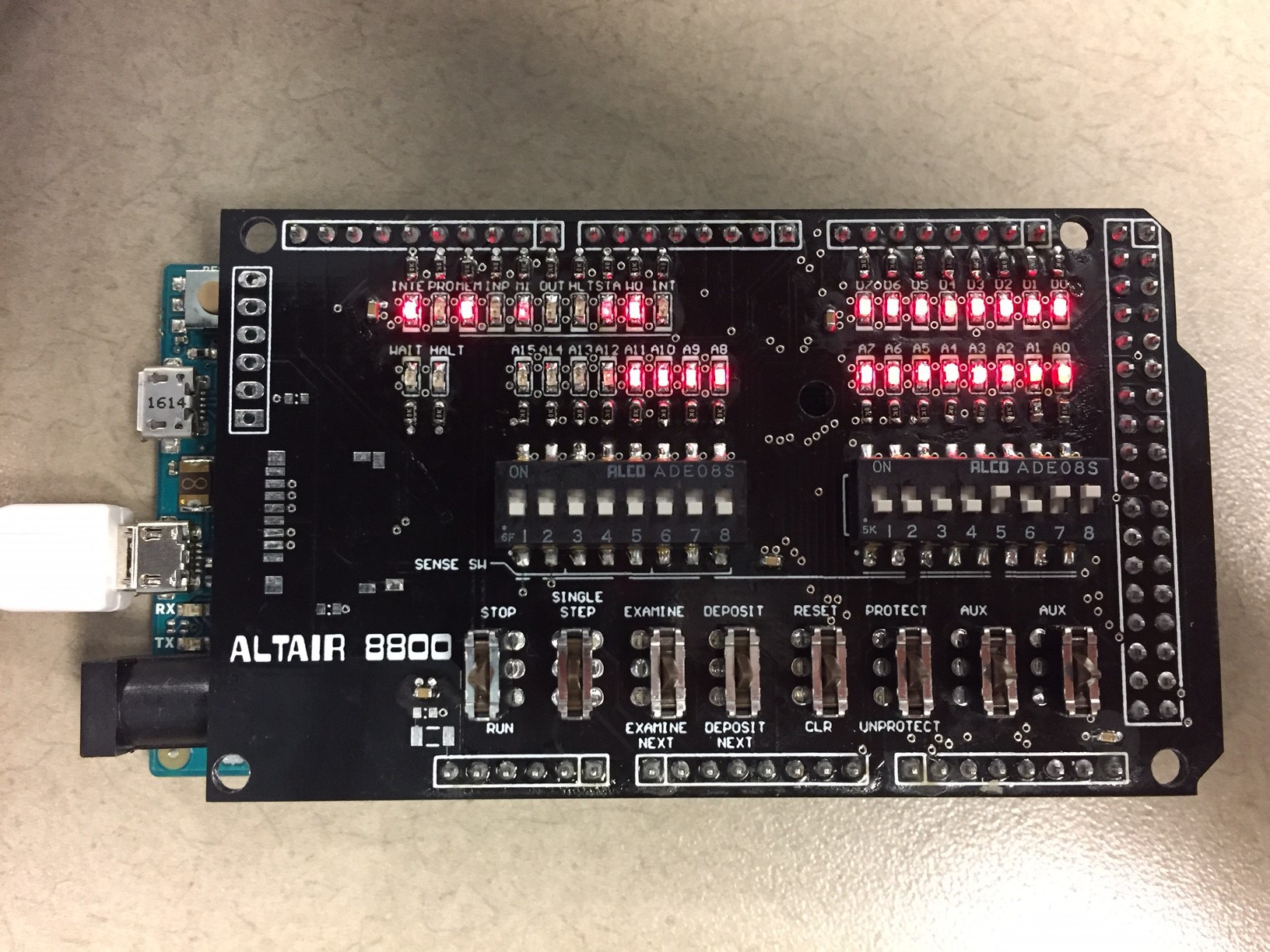

03/08/2017 at 17:43 • 1 commentI have my primary objectives of switches and lights done. And it works!

There are two errors which I discovered. One pairs of pins going to A4 and A5 are swapped in the footprint artwork for the dual row connector. So those LEDs are swapped. Not a big deal - I can hack the software to get them to display correctly. The second is I have my STOP/RUN switch backwards. Again, I can swap it in software. If I do another board spin, I will fix those errors and the via solder mask problem.

I have kill-the-bit up and running and it looks like it's working ok. I haven't finished checking every LED and switch, so there may be more hidden errors. Next is get the microSD card reader up and running so I can have disks!

-

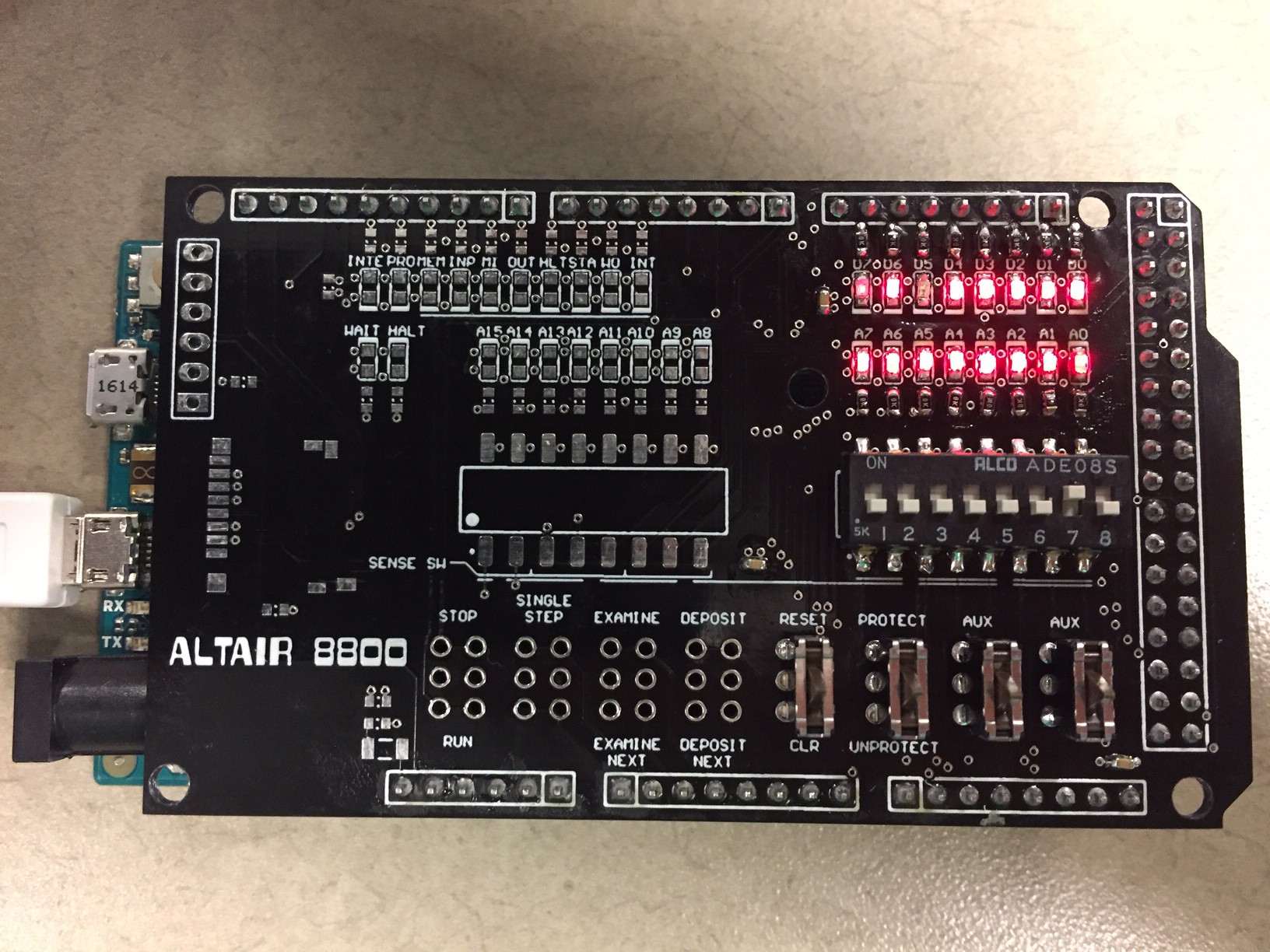

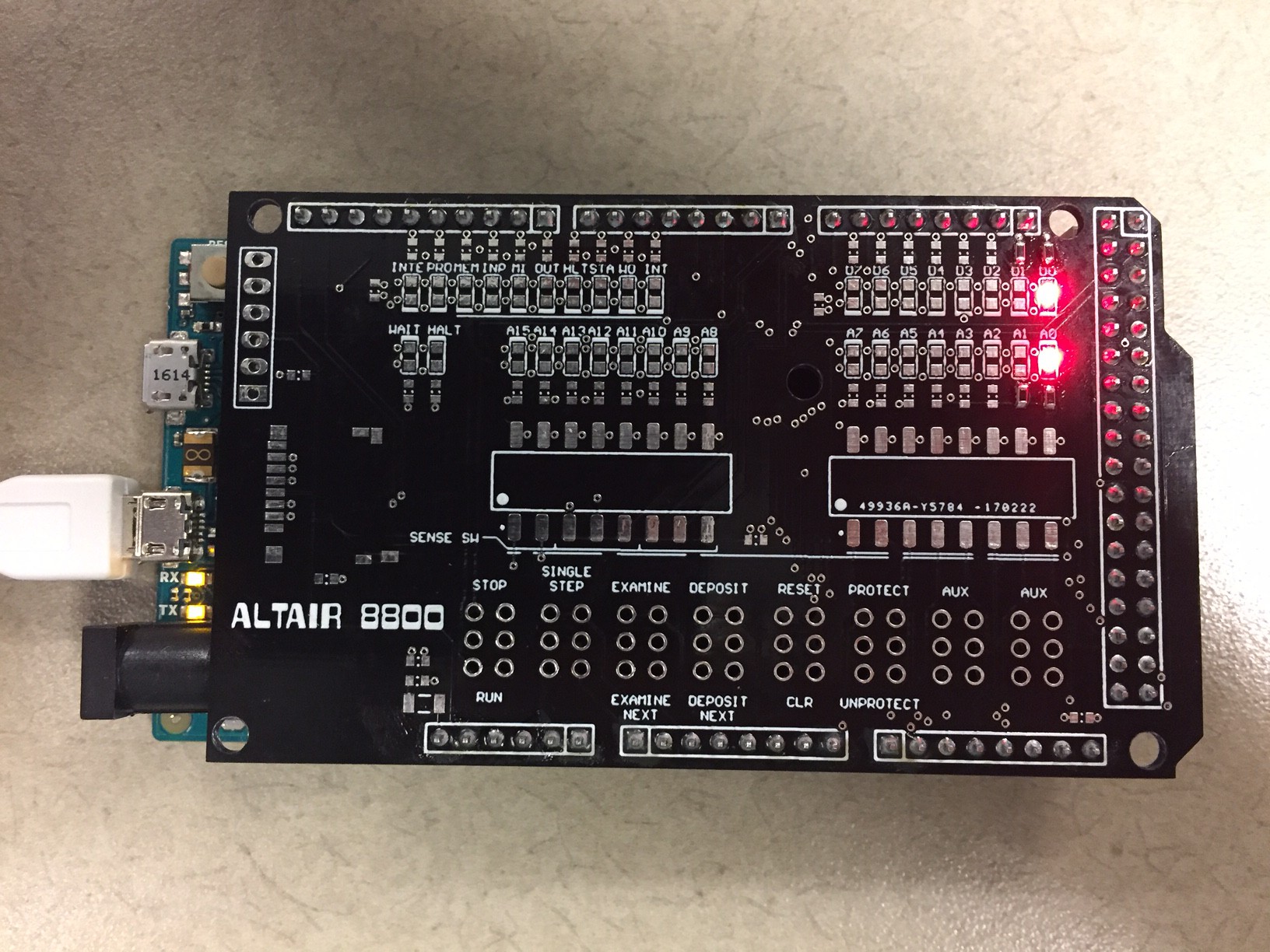

Halfway

03/07/2017 at 20:51 • 1 commentI finished the right side of the board. I checked the DIP switches for polarity, and then soldered the remaining right-side LEDs, resistors, DIP switches, and the four right momentary switches. Since the software has pre-loaded programs, I used those to check everything. For example, setting my DIP switches to 0000 0010 and hitting the AUX1 toggle loads the kill-the-bit program (shown running below). Once I get everything working, I'll put up some videos showing it running.

Next up is left side LEDs,resistors, DIP switches, and the remaining momentary switches. If I get that working, then all my primary goals are achieved. The secondary goals are to get the microSD card reader working, and then maybe the bluetooth module.

-

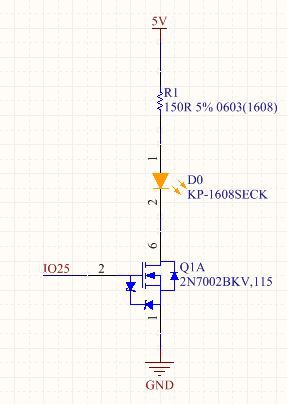

LED brightness toned down

03/07/2017 at 18:40 • 0 commentsI replaced the 1k current limiting resistors with 10k resistors and it's much more bearable to look at now. It may not come across in the photos.

I haven't uploaded a schematic just yet since I'm still making some small changes with components. But here's the LED driver. R1 is now 10k.

![]()

Next I need to check the polarity of my DIP switches. I want "up" to be "on" like in the Altair. Which means a short on the switch. I think that means I need to install the switches upside down, but that's ok.

-

My eyes!

03/06/2017 at 21:10 • 6 commentsI got the standoffs soldered and two of the LEDs. I wanted to check the brightness on the LEDs before soldering all of the resistors. I decided 250 Ohms was still too much current, so I started with a 1kOhm resistors. I put two on the board and tried them out. And they were still very bright.

There's no big diffuser on smalll LEDs like this, so all the brightness is very concentrated. I ended up writing a custom program with analogWrite and jumpered with a wire over to the LEDs to see what would be an acceptable brightness. I think if I had about 1/10th of the current it would be fine. So that means 10kOhm resistors. I'll remove the 1k and replace with 10k.

I also found that with this many headers it's very tough to get the shield on and off easily. Perhaps with more repeated on/off cycles it will get easier.

-

Vias

03/04/2017 at 21:58 • 0 commentsI realized that I forgot to change my via settings. This was my first try at making a board in Altium. By default it doesn't place the solder mask over the vias. I prefer having the solder mask over the vias. It makes soldering by hand a little easier. In this case, the small amount of solder I place on the resistor and LED pads gets sucked down into the via. Not a big deal, but makes assembly just a little more difficult.

-

PCBs!

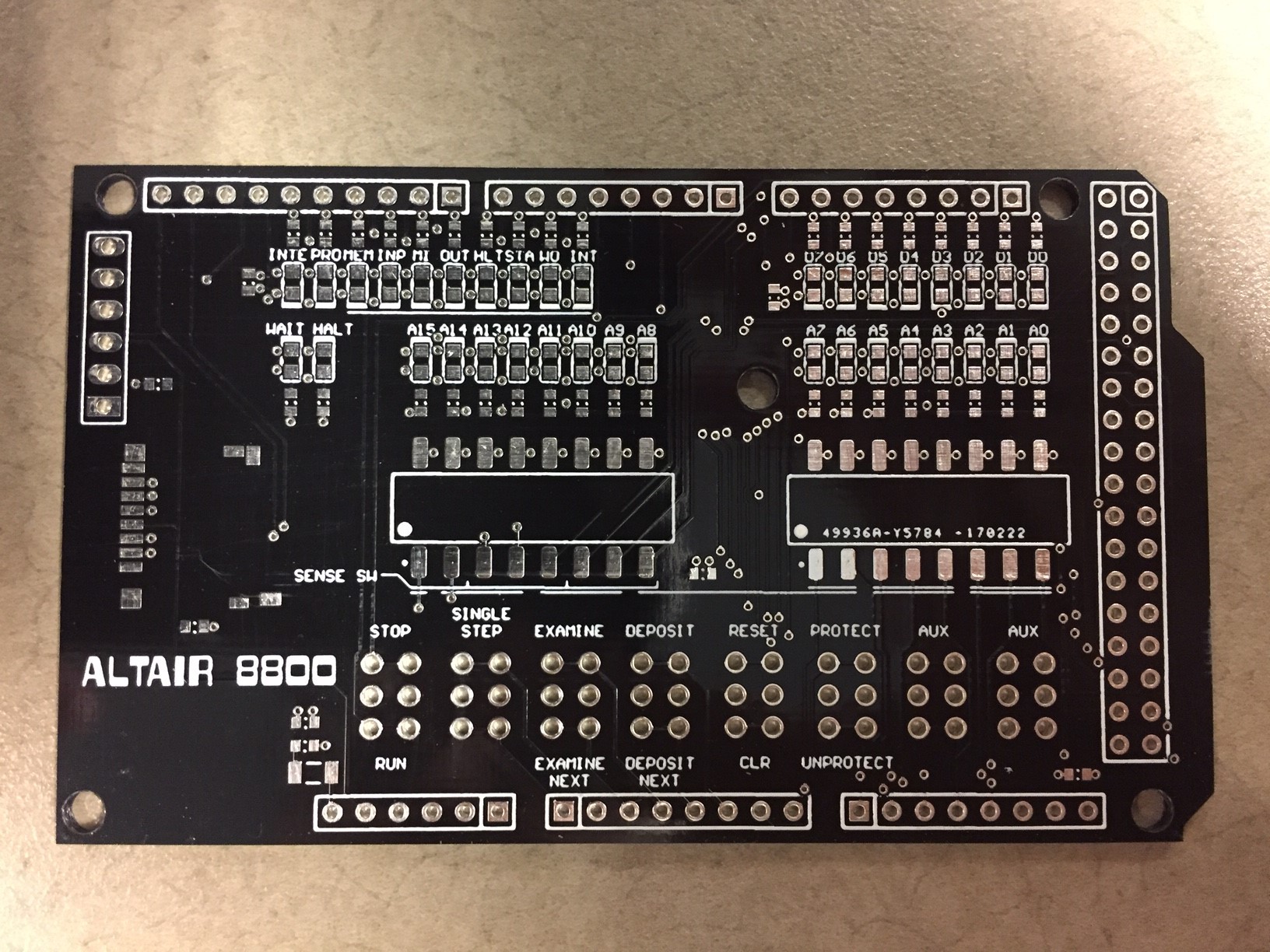

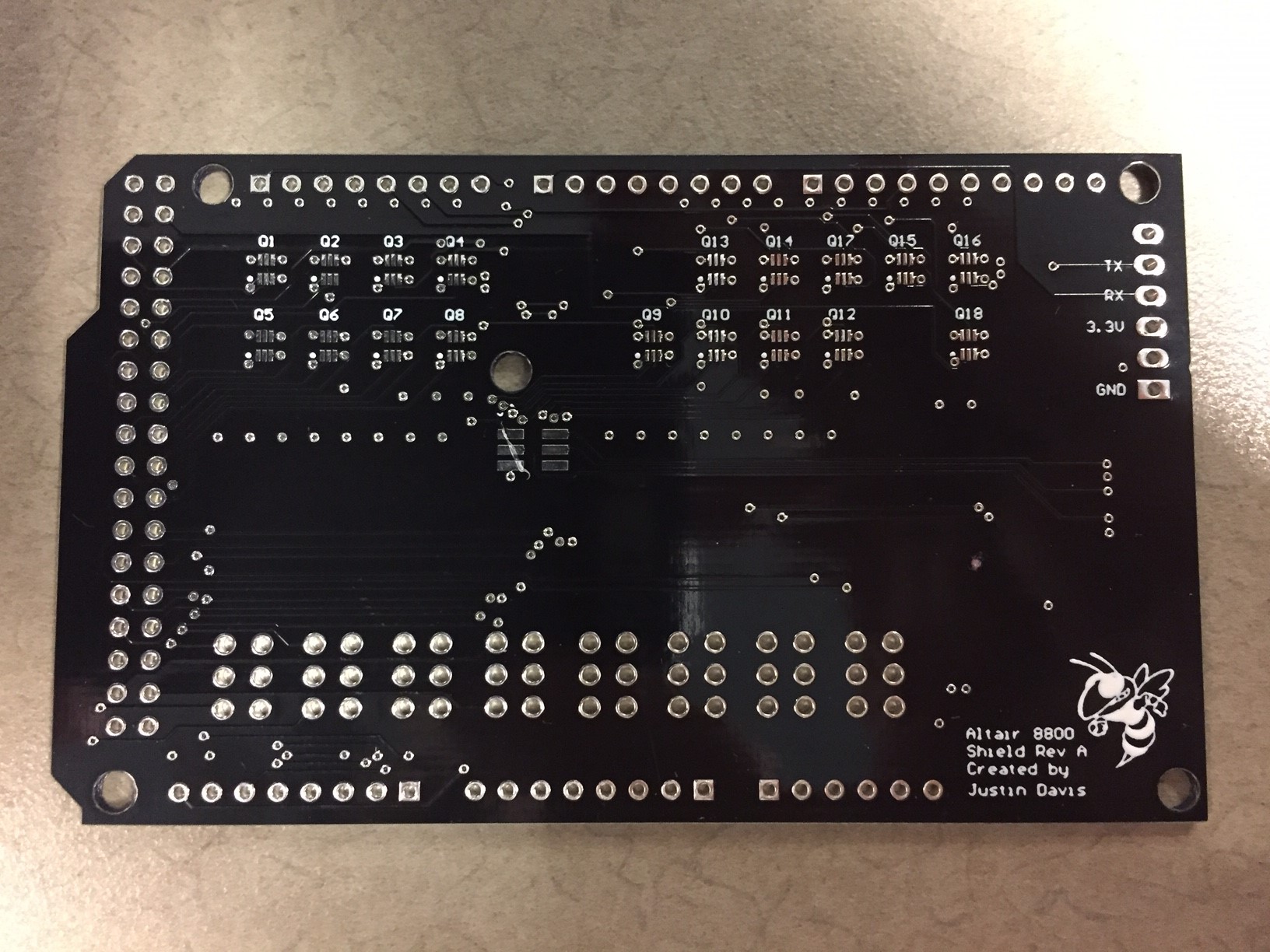

03/03/2017 at 13:04 • 0 commentsLookin good! The black mask really makes the silkscreen pop. If I were to do this again, I might move the LED resistors to the bottom side. They kinda look crammed in there. I also added a Buzz on the backside since I've never put artwork on silkscreen before. And the Altair 8800 logo looks good too. Now to begin the long process of soldering and check out.

-

PCB shipped

02/28/2017 at 21:01 • 0 commentsPCBs shipped today! Supposed to arrive tomorrow. I'll put photos up when I get them.

Altair 8800 front panel Ardiuno shield

A very small fully-functional interface for an Arduino Due emulating an Altair 8800