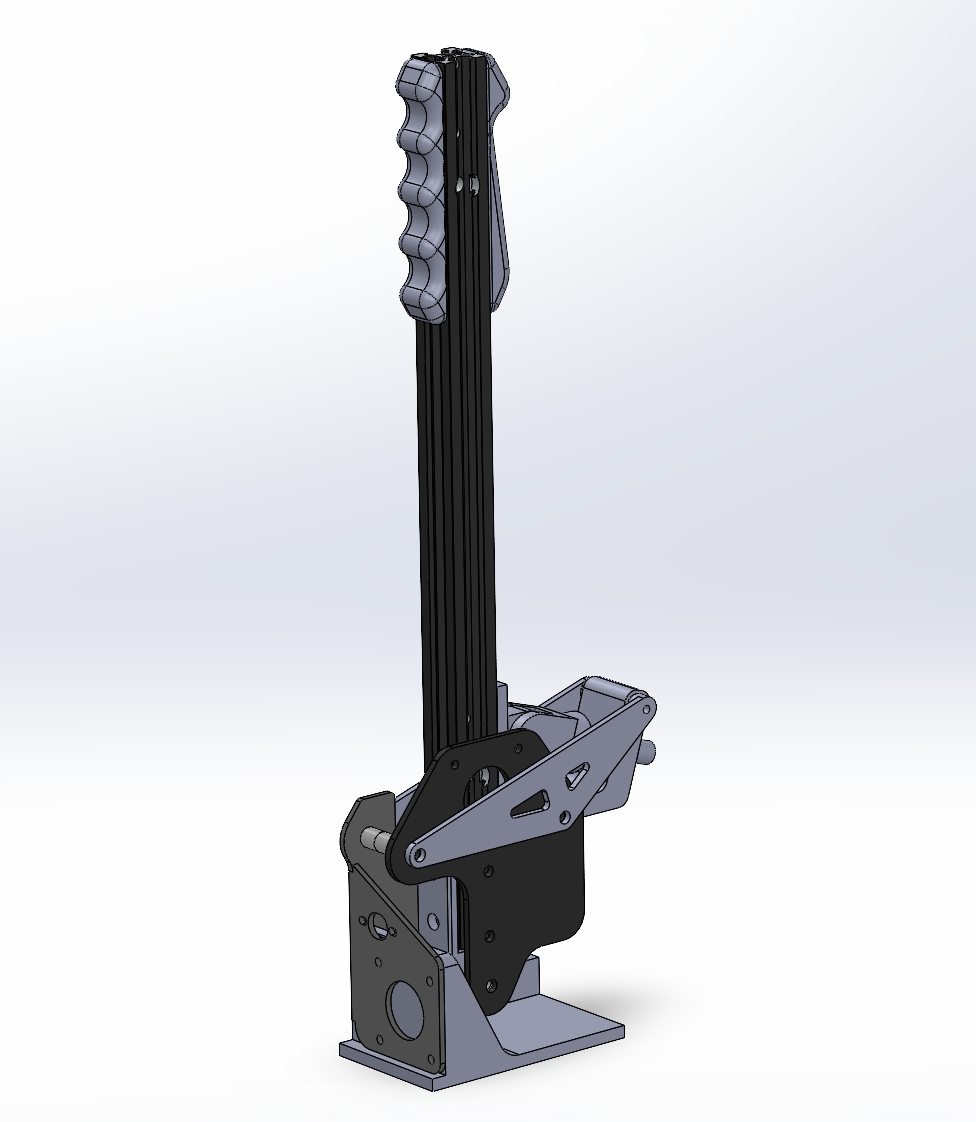

The mechanical design is now a bit more fleshed out. The compressive springs I have are too small to fit over the bolt I am using for the plunger, so I will need to rig up some way to use an extension spring. I am bad at making ergonomic things but I did my best to make some comfortable looking grips.

Now I need to make a place for the magnet and all the electronic components. It would be cool to route the wires through the hole in the front of the base that is typically used by a motor shaft, but I'm not sure if there will be enough room.

Now I need to make a place for the magnet and all the electronic components. It would be cool to route the wires through the hole in the front of the base that is typically used by a motor shaft, but I'm not sure if there will be enough room.

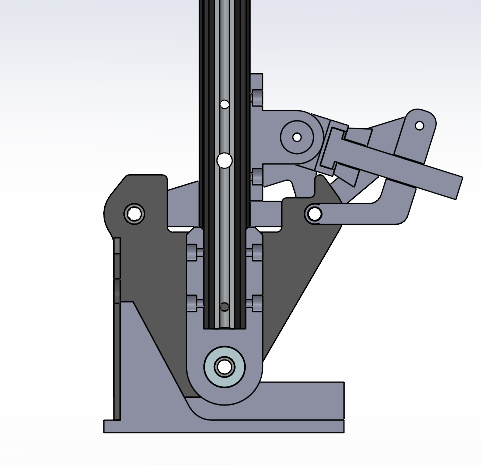

The bolt used as the plunger will be held into its pivot by a set screw. The bracket that the plunger works through is mounted to the frame by slipping over the spacers in the rear, and is braced by two side brackets. I am hoping a long 3mm bolt through the rear most mounting hole (top right of cross section) will provide more structural support than a continuous 3d printed part where the force might cause layers to shear apart at the sides. I will also need to thicken the handle pivot attachment to reduce any lateral movement of the handle during use.

I need to tackle the least fun part of the project now which will be putting my 3d printer back together

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.