Here, we are using Rasperry Pi 4 combined with the DFRobot's 5'' 800x480 IPS display, and both are being powered by a battery pack circuit we created for a previous project. We are using a 11.1V lithium cell battery pack. The Pi 4 and Display need stable 5V to operate so to step down the 11.1V from the battery pack, we prepared a custom Buck converter circuit that provides stable 5V 3A to power the Pi.

Here, we're using a Raspberry Pi 4 with the DFRobot's 5'' 800x480 IPS display, both powered by a battery pack circuit we created for a previous project. We're using a 11.1V lithium cell battery pack.

The Pi 4 and display require a stable 5V to function; therefore, we designed a customized Buck converter circuit to step down the 11.1V from the battery pack, providing a stable 5V 3A to power the Pi.

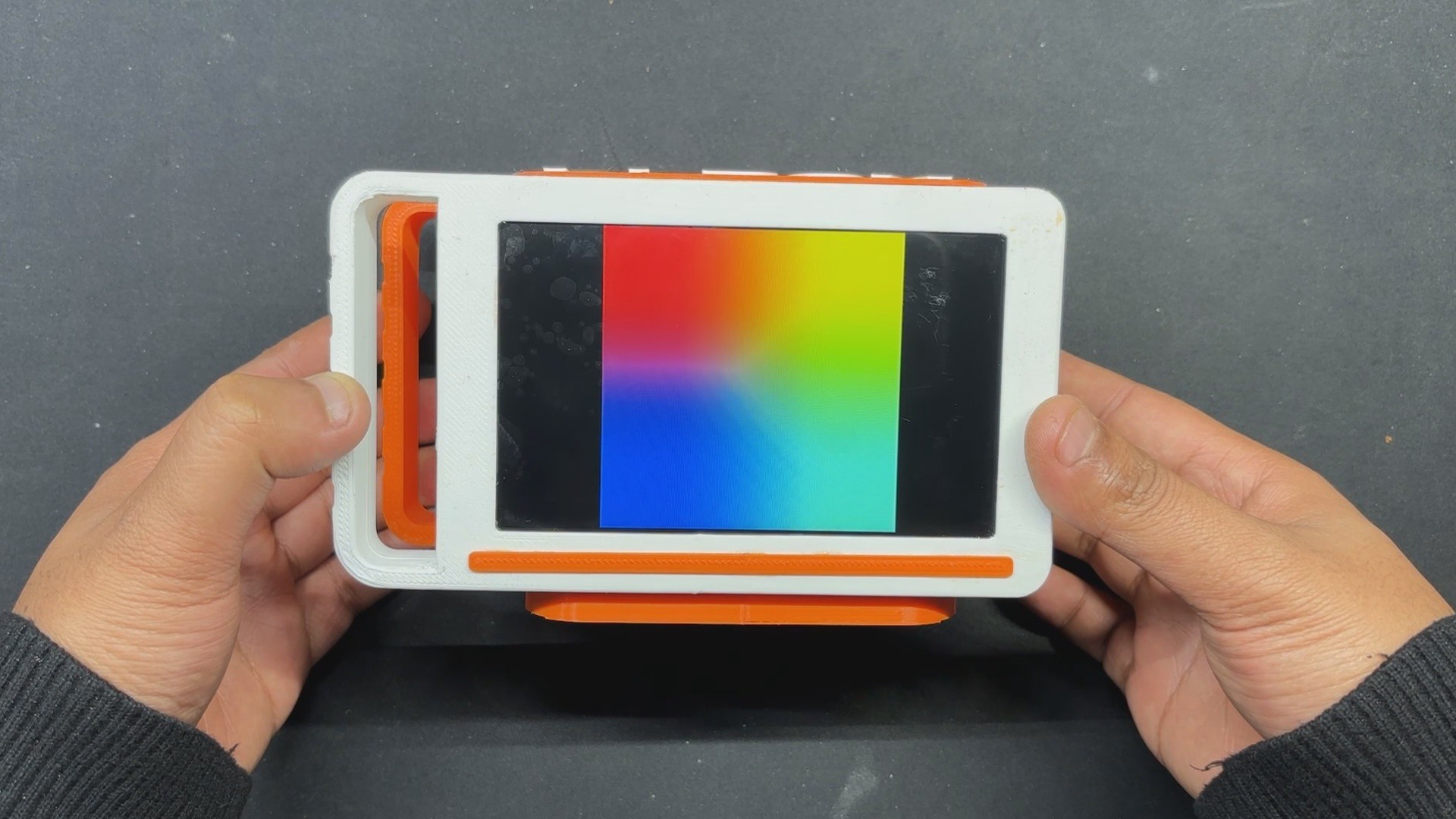

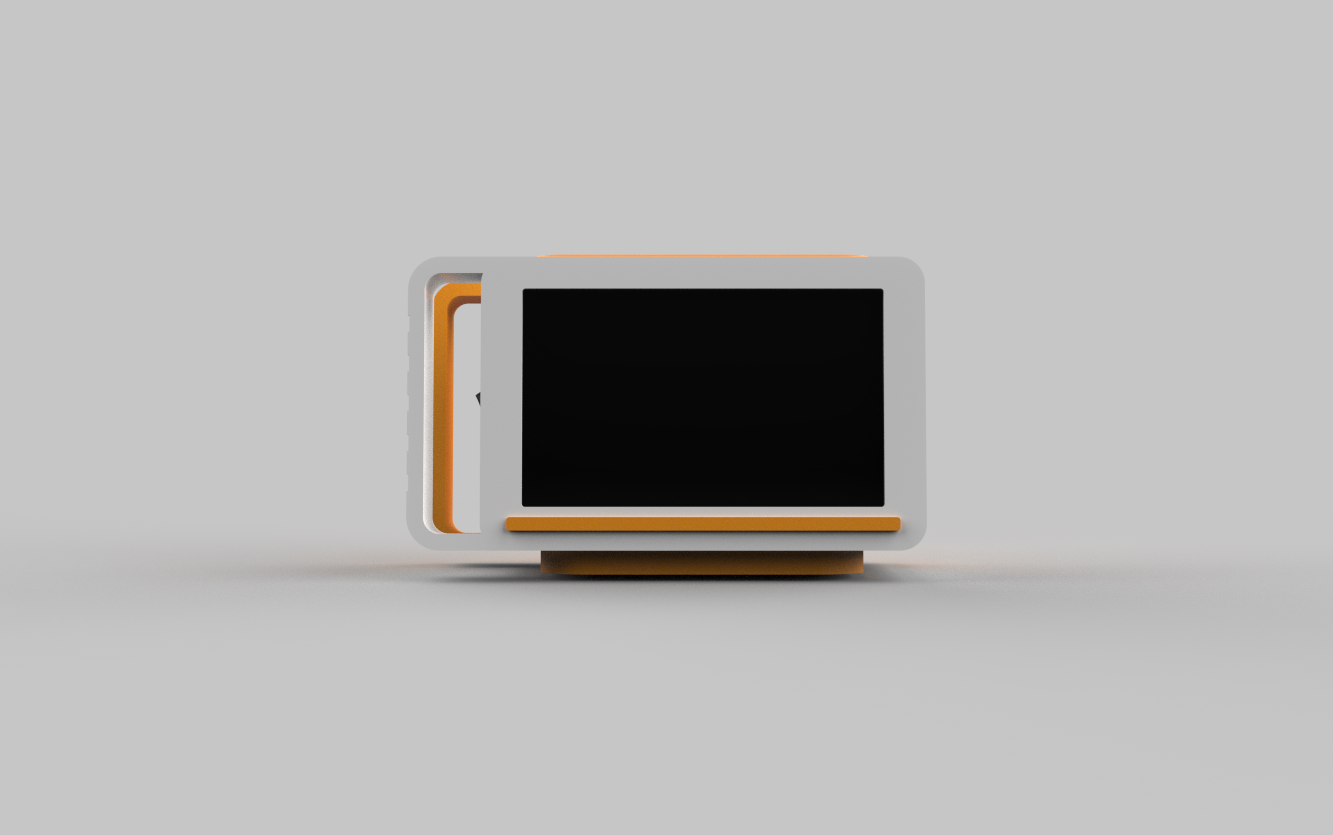

In terms of design, we created a box-like enclosure that is divided into two halves: the front section houses the display with Pi 4, and the back section holds the battery pack circuit in place. To improve the design's looks, we added a handle-like section to the left side of the front and back parts, as well as printed the enclosure in two colors to give the entire design a duotone vibe.

This device can be used as a Pi desktop or with an OS such as Octoprint or other general-purpose OS. One usage for this device was as a game emulator station, and YES, THIS SETUP CAN RUN DOOM.

Raspberry Pi 4 and 5" Display

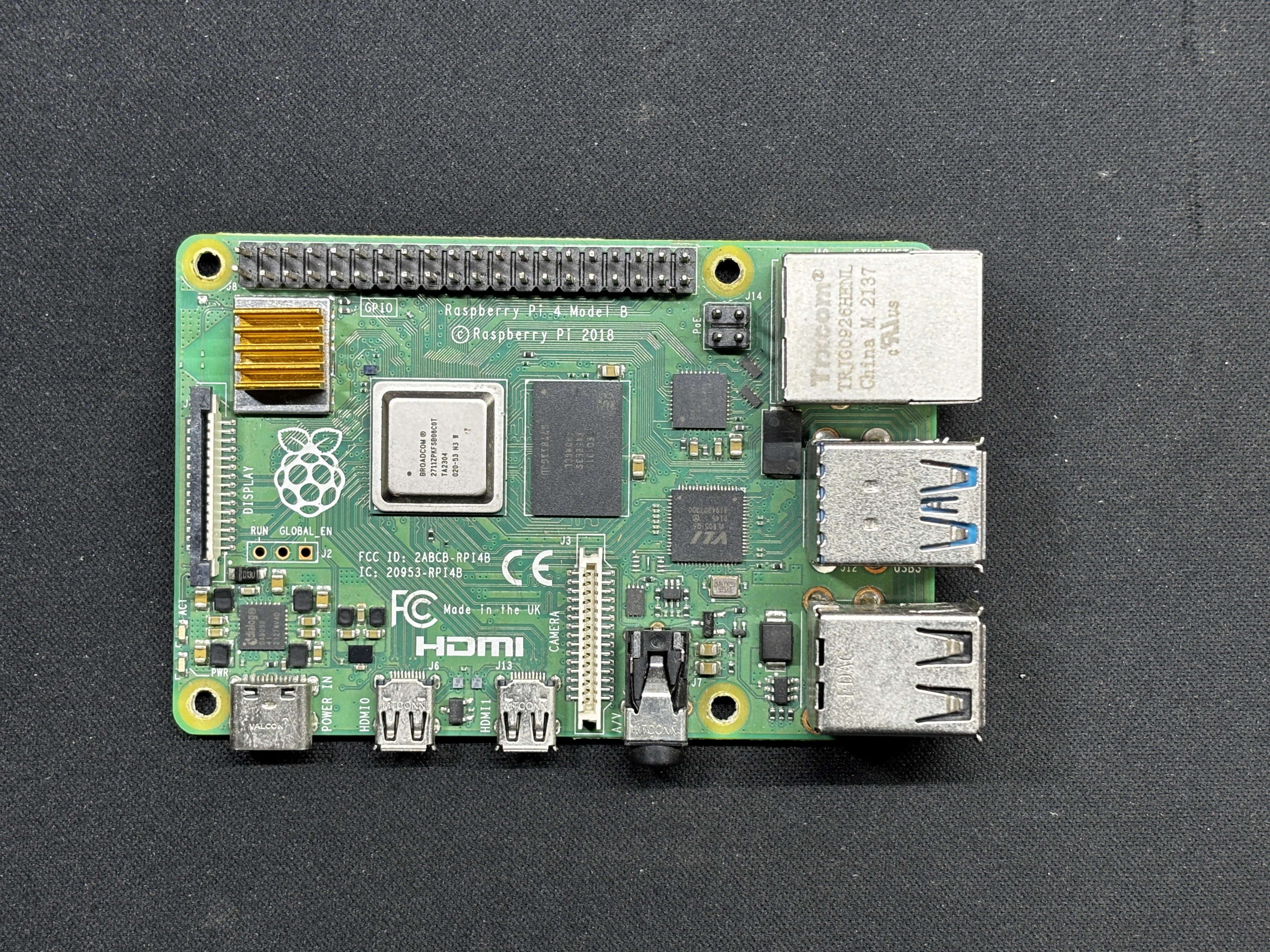

We are using the Raspberry Pi 4 Model 4GB variant in this project, which is a significant improvement over the previous Raspberry Pi 3 in terms of power and functionality.

It features a quad-core 1.8GHz processor, up to 8GB of RAM, and dual 4K monitor support via micro-HDMI ports, making it suitable for a variety of demanding applications.

It offers excellent connectivity options, including Gigabit Ethernet, dual-band Wi-Fi, and Bluetooth 5.0, ensuring fast and reliable network connections. The inclusion of two USB 3.0 ports and two USB 2.0 ports provides enhanced data transfer capabilities. This model is also equipped with advanced multimedia support, including H.265 video decoding and OpenGL ES 3.1, making it an ideal choice for multimedia projects

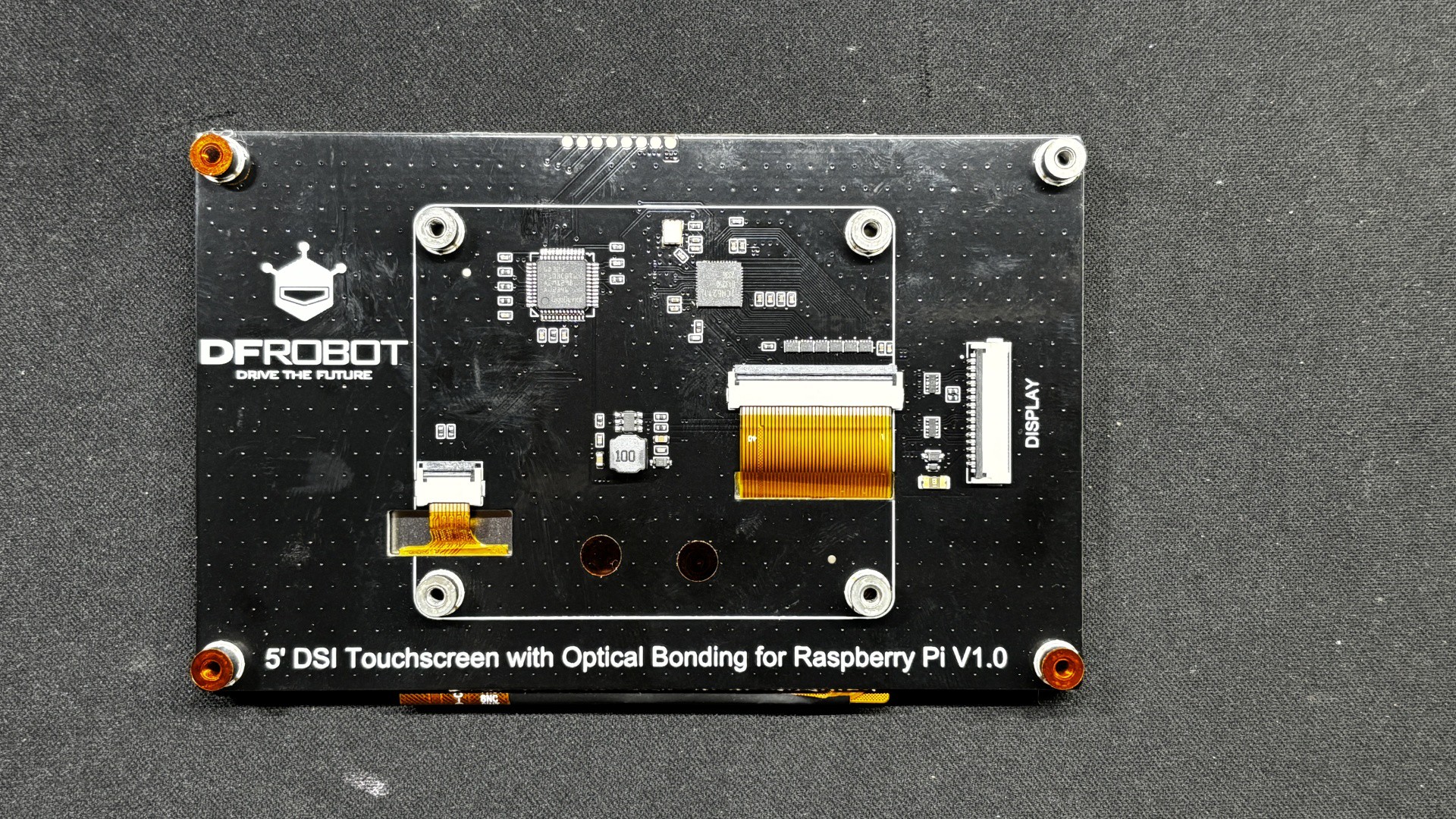

As for the display, we are using the DFRobot's 5'' 800x480 IPS display, which is an IPS display that supports Raspberry Pi DSI display interface and comes with a capacitive touch panel

The display operates at a voltage of 3.3V, supplied by the Raspberry Pi display interface, with a maximum operating current of 320 mA and a screen-off current of 100 mA. It features a resolution of 800x480 and connects via the Raspberry Pi DSI video interface. It supports up to 5 touch points, with an 80-degree viewing angle on all sides.

The color depth is RGB888, offering 16 Mega True Colors, and the display has a refresh frequency of 60Hz. Additionally, the IPS panel includes optical bonding for improved brightness and clarity, anti-fingerprint and anti-glare coatings for better visibility in various lighting conditions.

3D Design

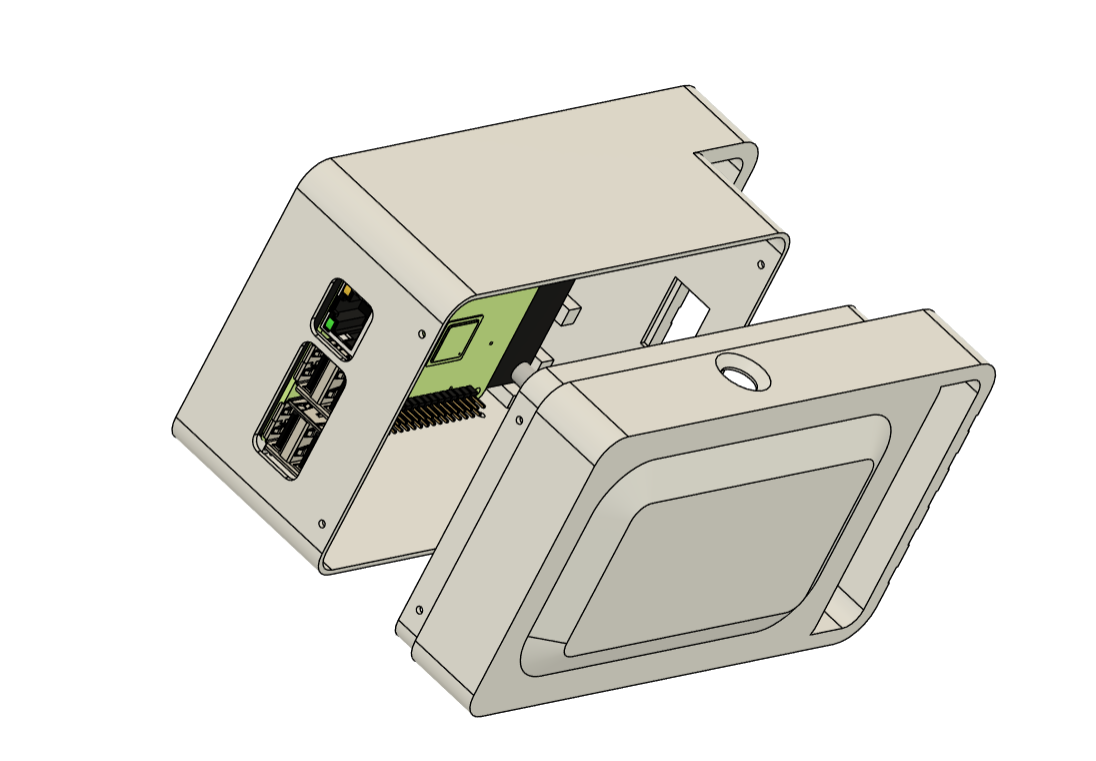

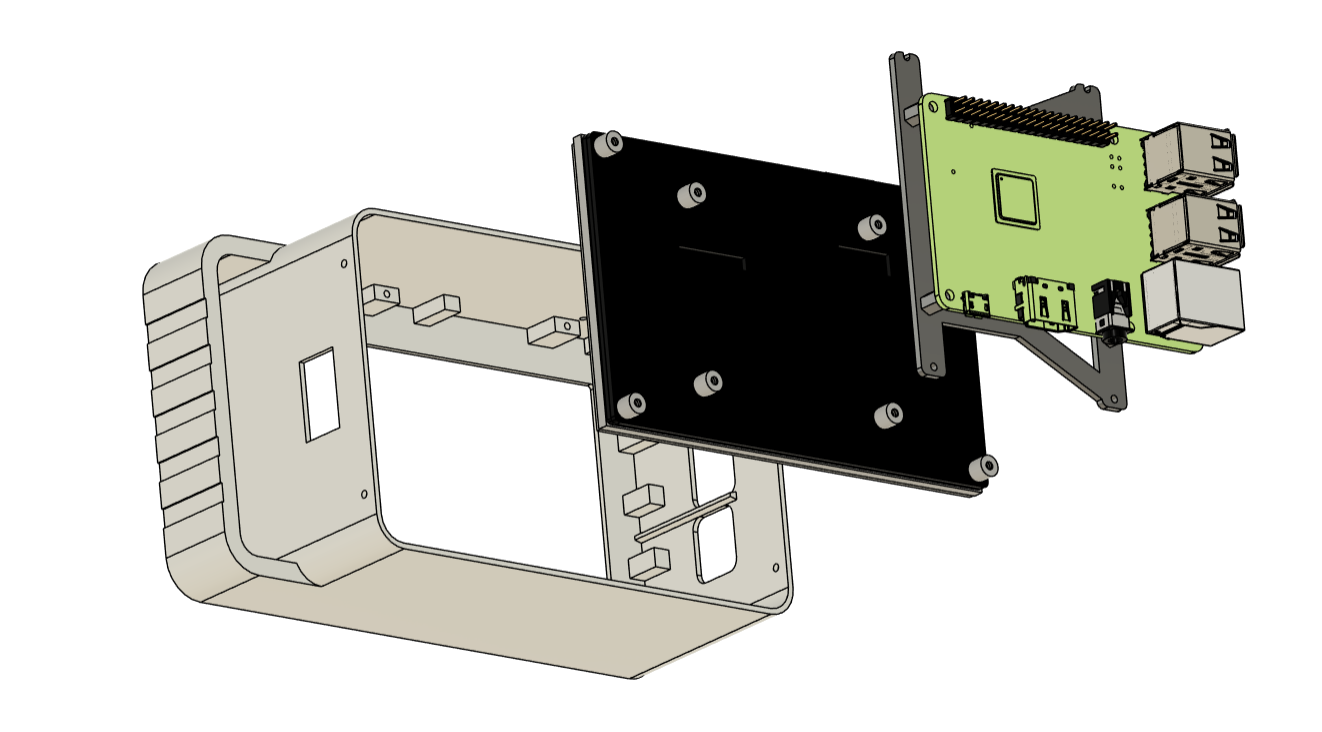

This project begins with the creation of the model, which began in Fusion360 by importing the model of the 5" display, Raspberry Pi, and Battery Pack Cirucit into the design. All three crucial components are positioned such that the display is at the front, and the Pi is placed behind the display but not on the mounting holes given on the back of the display, but the Pi is shifted slightly left so that we can access the I/O from the left side of the model.

The battery circuit is positioned behind the Raspberry Pi. By arranging the components in their proper positions, we started forming a box-like body around them, with the display at the front, the Pi in the center, and the battery pack circuit on the rear. We designed the model and divided it into two sections, with the front section housing the display, Raspberry Pi, and power switch in place. The battery pack circuit is housed in the second half, which is the back.

In addition, we designed a Pi holder portion to keep the Raspberry Pi 4 in place inside the front section. The Raspberry Pi 4 is connected to this Pi holder component by four hex standoffs.

We put two handles on both halves to give the model a little industrial element, and the rocker switch is positioned between these two handles.

Also, to give the model's aesthetics a duotoned feel, we printed every part in only two colors, PLA, white, and orange.

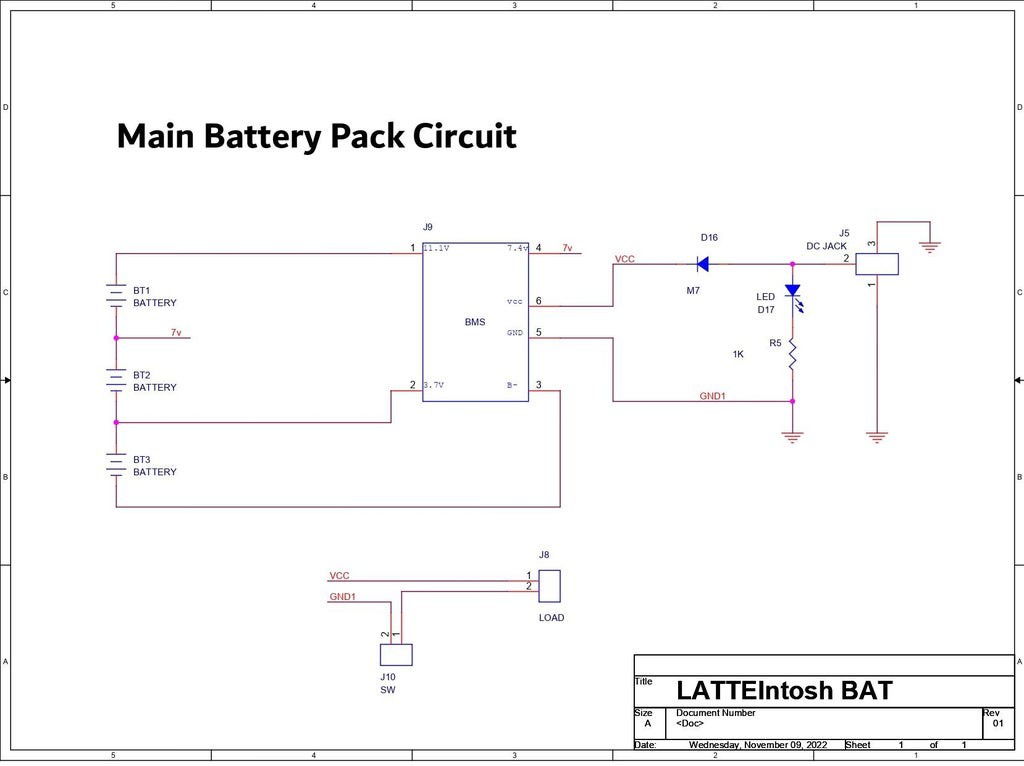

Battery Pack Circuit

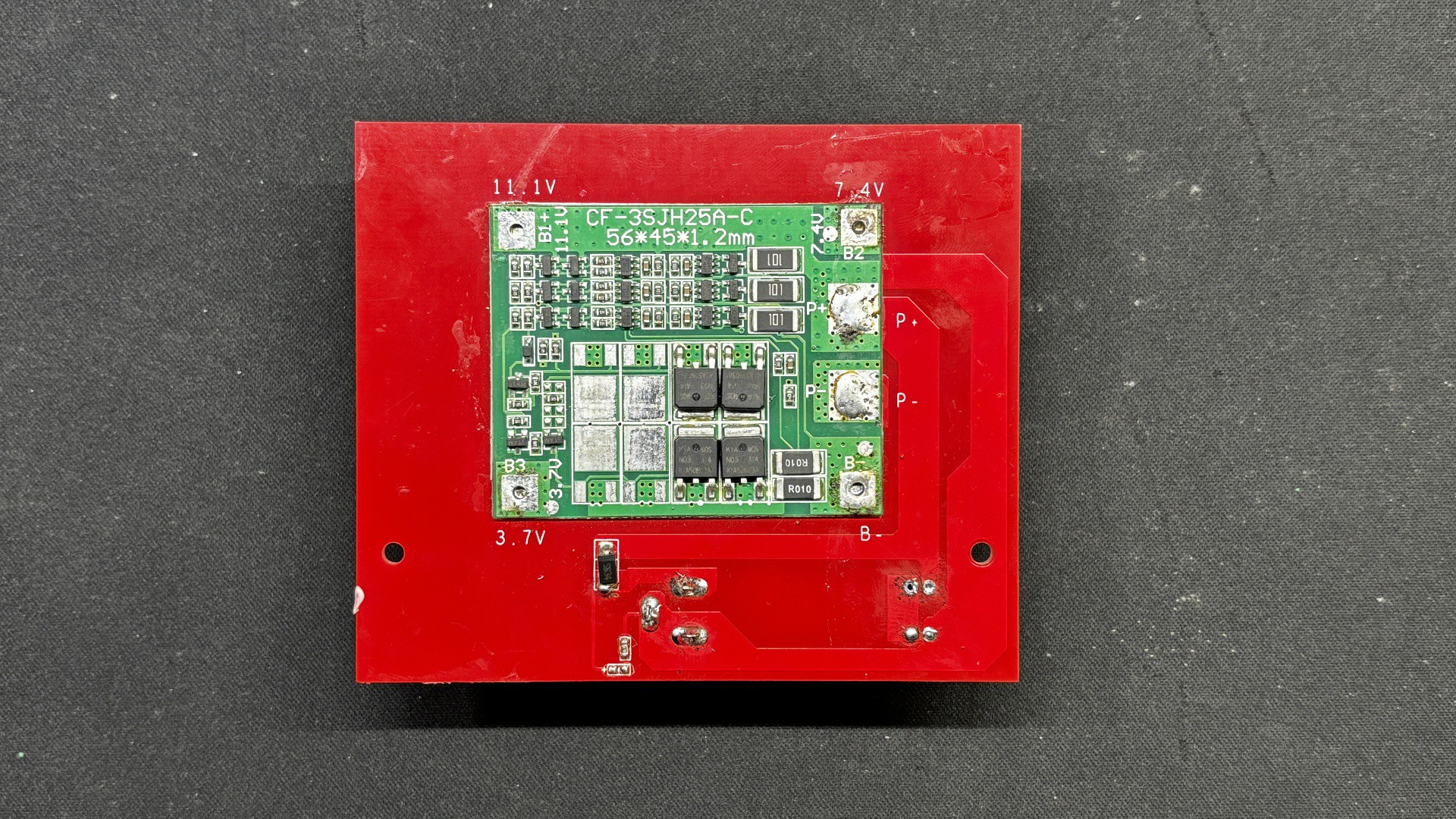

For the power source, we are using one of our previously created battery pack circuit boards from an old project.

We basically have a circuit that comprises a BMS (battery management system) circuit coupled to three lithium cell holders. There is also a DC jack attached to a diode, which allows us to charge the cells using a 12V adaptor.

This board comes with three 3.7V, 2900mAh lithium cells.

Power Module Circuit

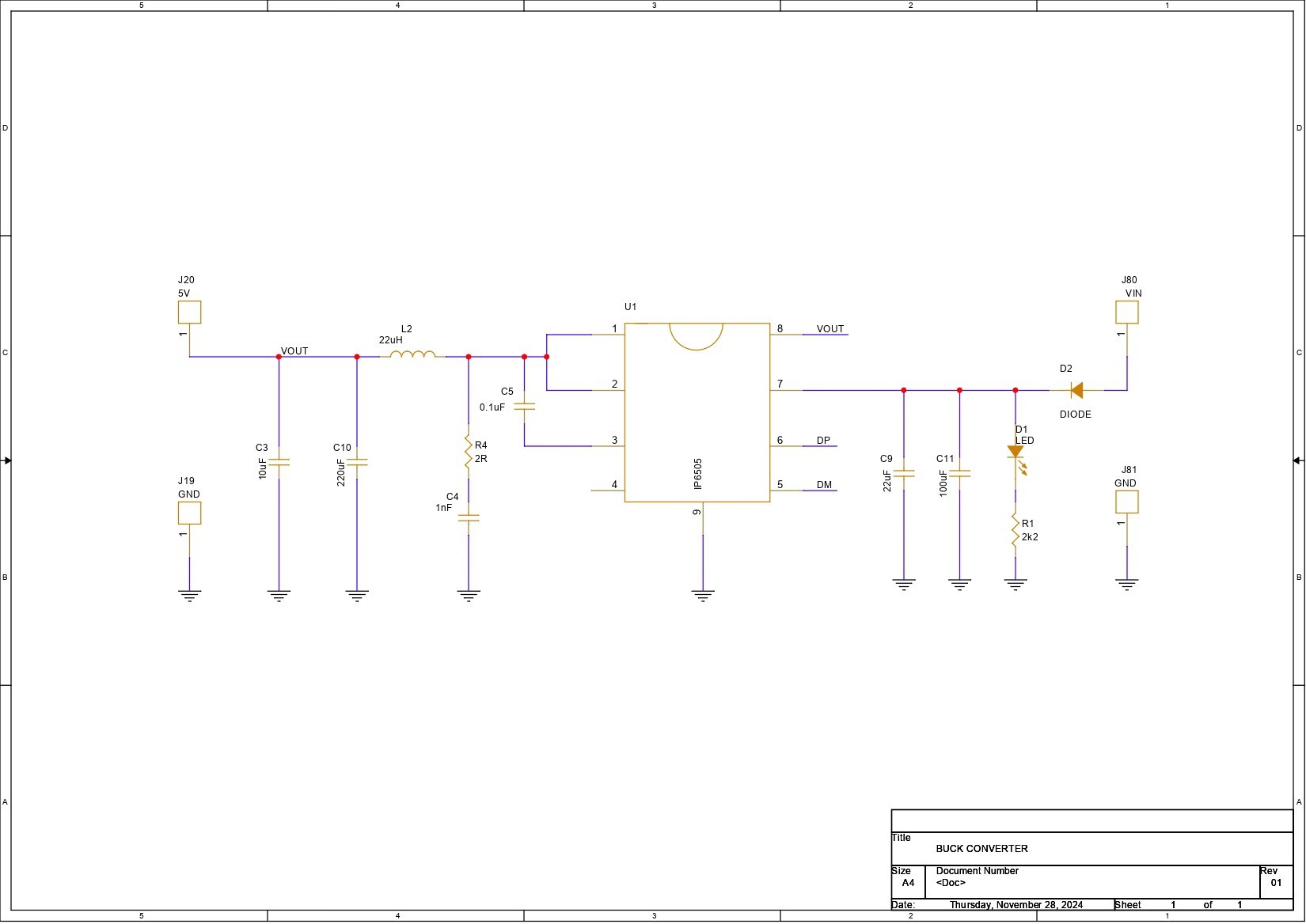

To power the Raspberry Pi and display arrangement from the battery pack circuit we are using, which is an 11.1V 3S Lithium cell battery pack setup, we needed a Buck converter board that would step down the 11.1V to a stable 5V to run the Raspberry Pi and display.

To address this issue, we selected a Buck Converter setup that includes the IP6505 IC, a step-down converter with an integrated synchronous switch capable of handling an output of up to 10A for fast charging protocols.

The IP6505 features an integrated power MOSFET with an output voltage range of 3V to 12V and an input voltage range of 10.5V to 28V. It can provide up to 24W of output power by automatically adjusting the voltage and current in line with the recognized quick charge protocol, more than enough for our Raspberry Pi 4 and display setup.

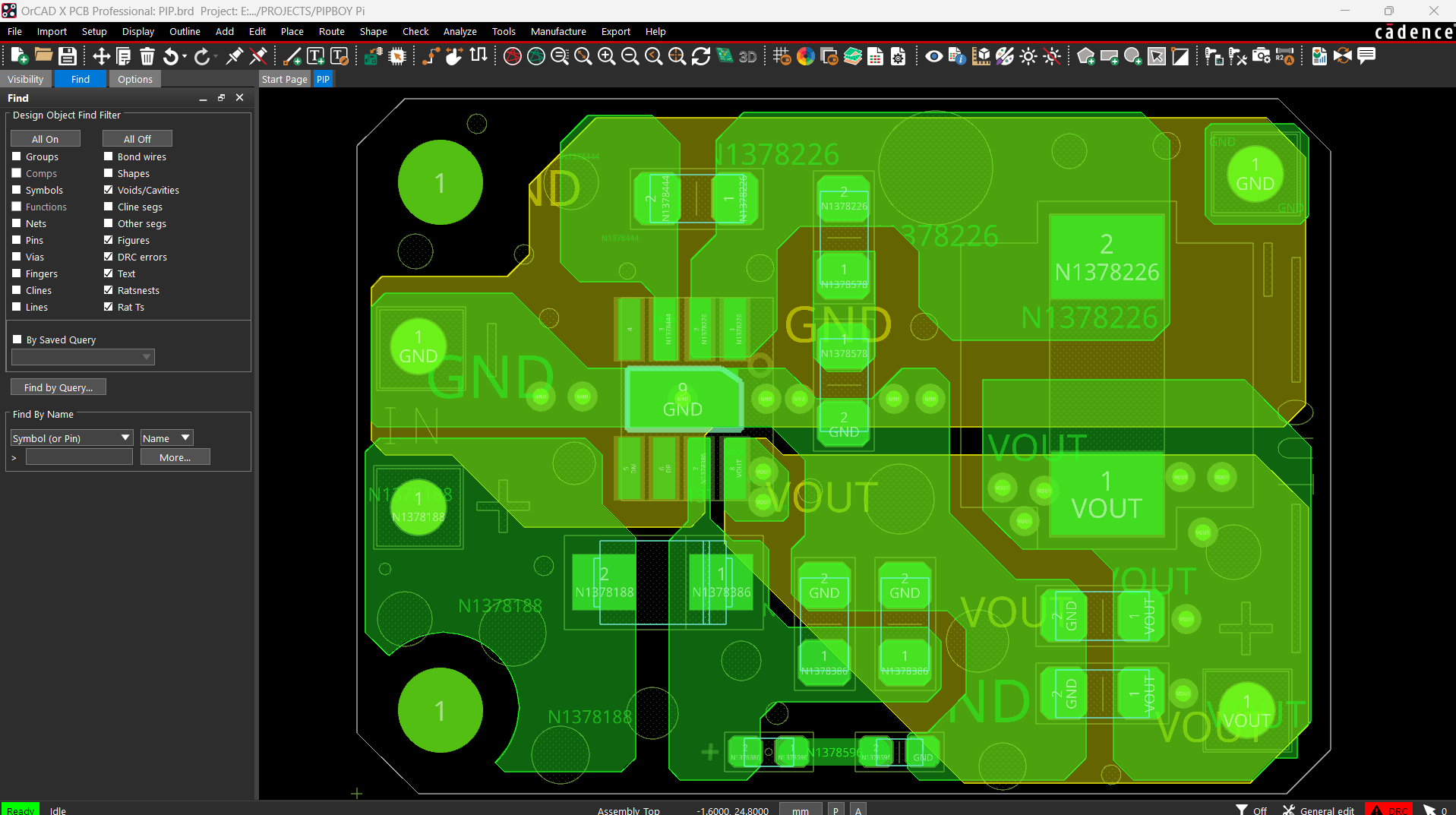

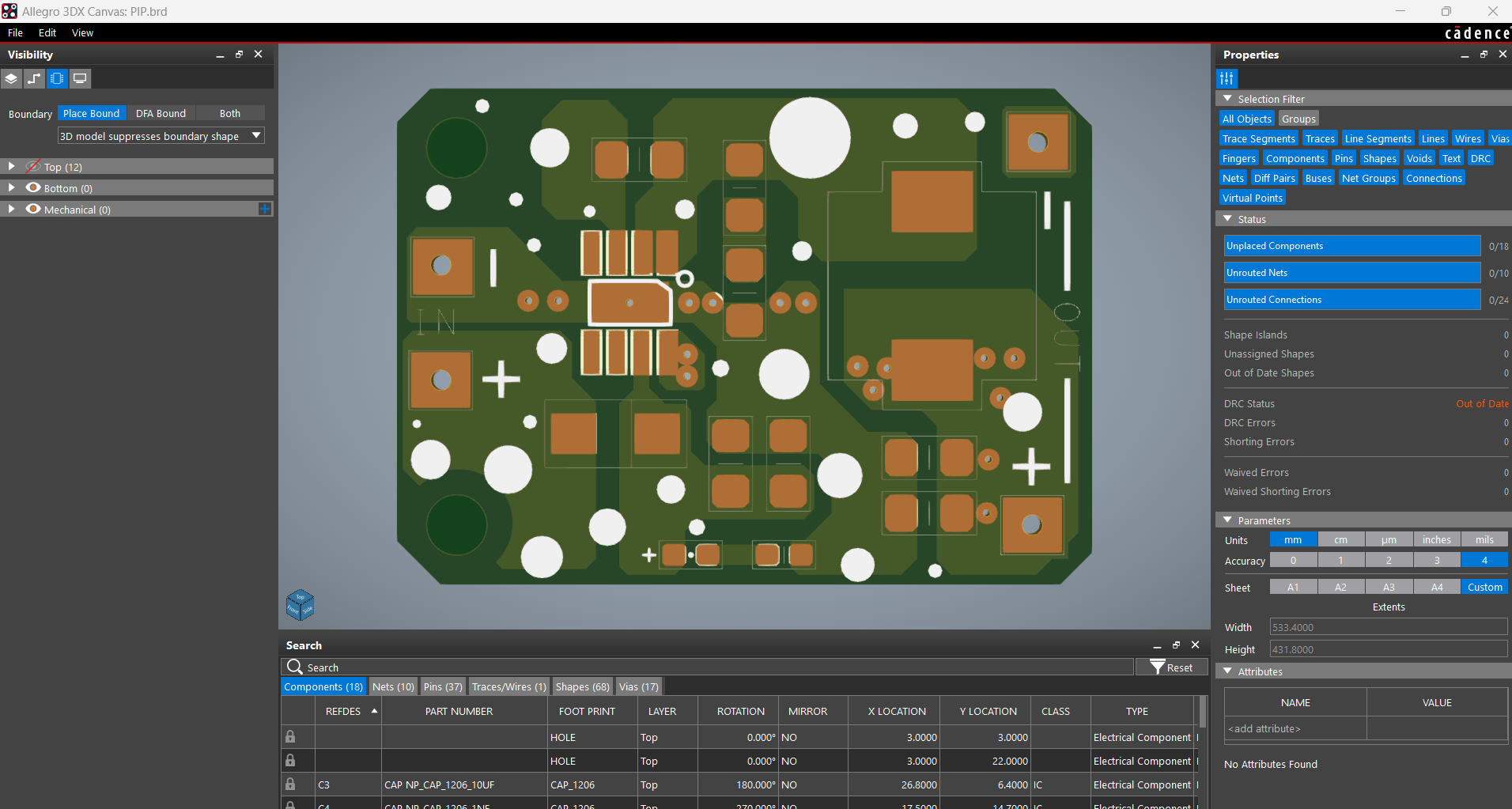

The schematic was initially created and customized following the datasheet's example layout. All of the components on this board are surface mount, which reduces the need for manual soldering.

HQ NextPCB Service

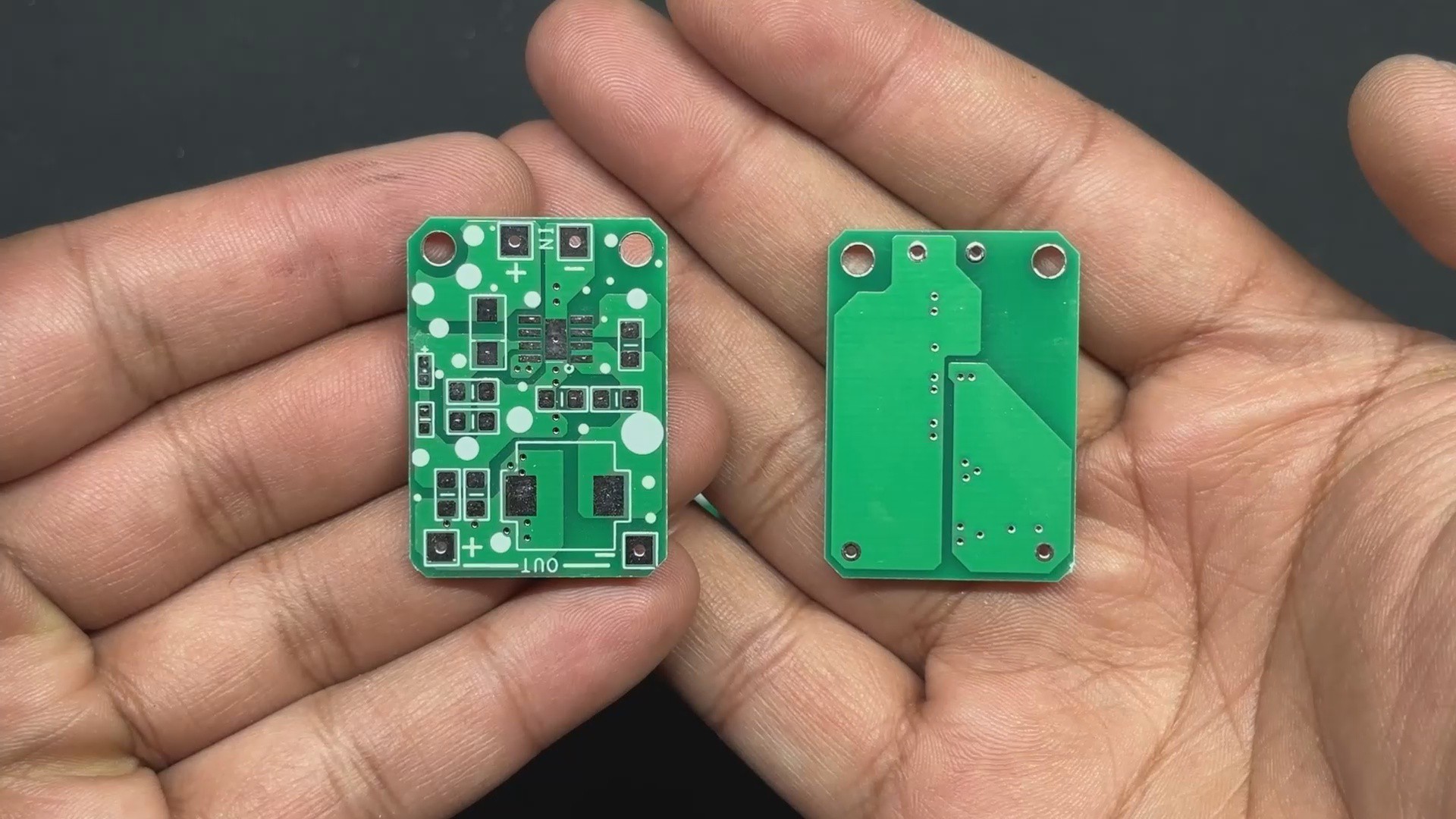

After completing the PCB design, we export the Gerber data and send it to HQ NextPCB for samples.

Gerber Data was sent to HQ NextPCB, and a Green Solder Mask PCB with White Screen was ordered.

After placing the order, the PCBs were received within a week, and the PCB quality was pretty great.

In addition, I have to bring in HQDFM to you, which helped me a lot through many projects. Huaqiu’s in-house engineers developed the free Design for Manufacturing software, HQDFM, revolutionizing how PCB designers visualize and verify their designs.

HQDFM: Free Online Gerber Viewer and DFM Analysis Tool

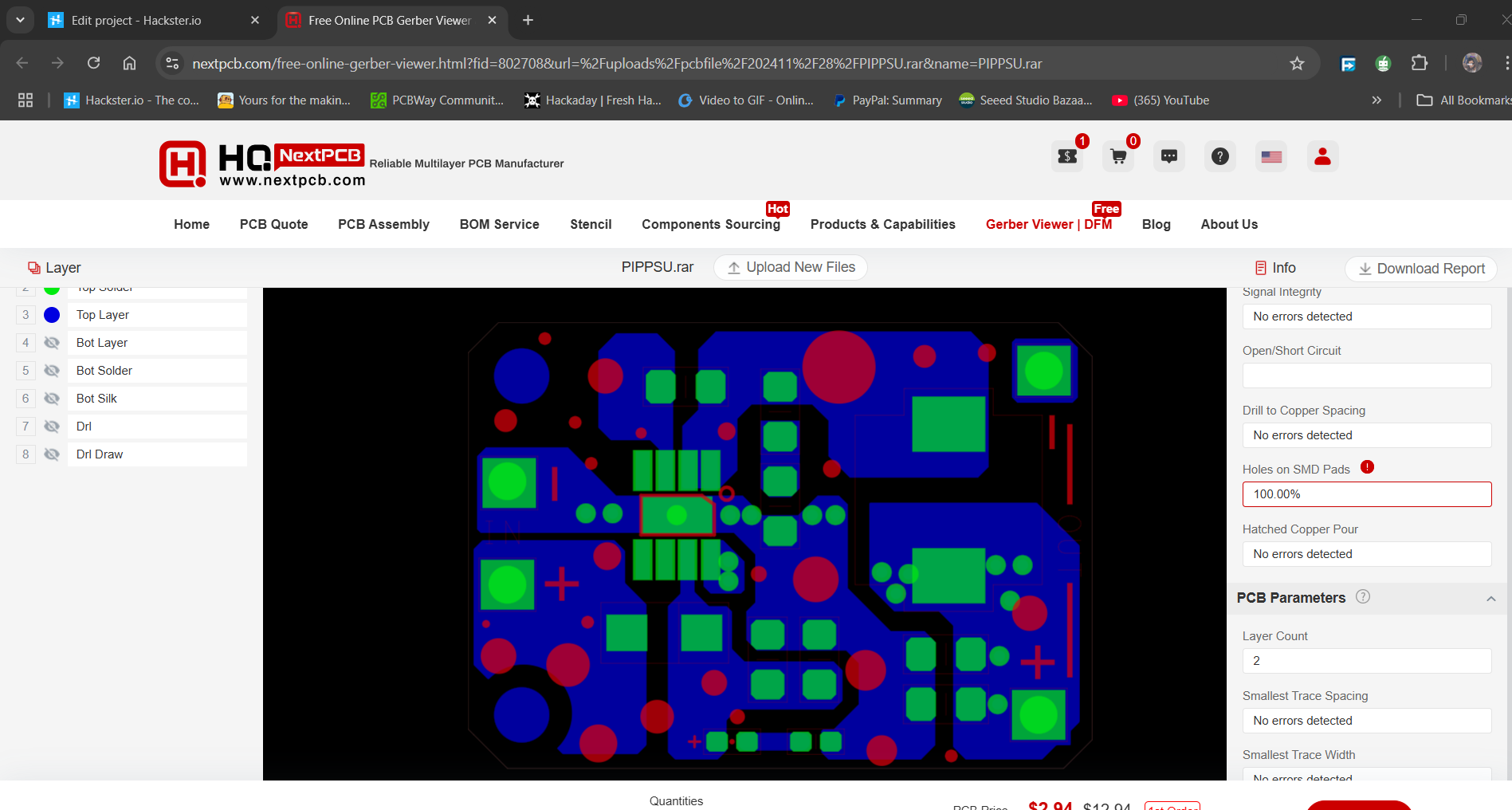

Also, NextPCB has its own Gerber Viewer and DFM analysis software.

Your designs are improved by their HQDFM software (DFM) services. Since I find it annoying to have to wait around for DFM reports from manufacturers, HQDFM is the most efficient method for performing a pre-event self-check.

Here is what online Gerber Viewer shows me. Would not be more clear. However, for full function, like DFM analysis for PCBA, you need to download the software. The online version only provides a simple PCB DFM report.

With comprehensive Design for Manufacture (DFM) analysis features, HQDFM is a free, sophisticated online PCB Gerber file viewer.

It provides insights into advanced manufacturing by utilizing over 15 years of industry expertise. You guys can check out HQ NextPCB if you want great PCB service at an affordable rate.

Arnov Sharma

Arnov Sharma