Background

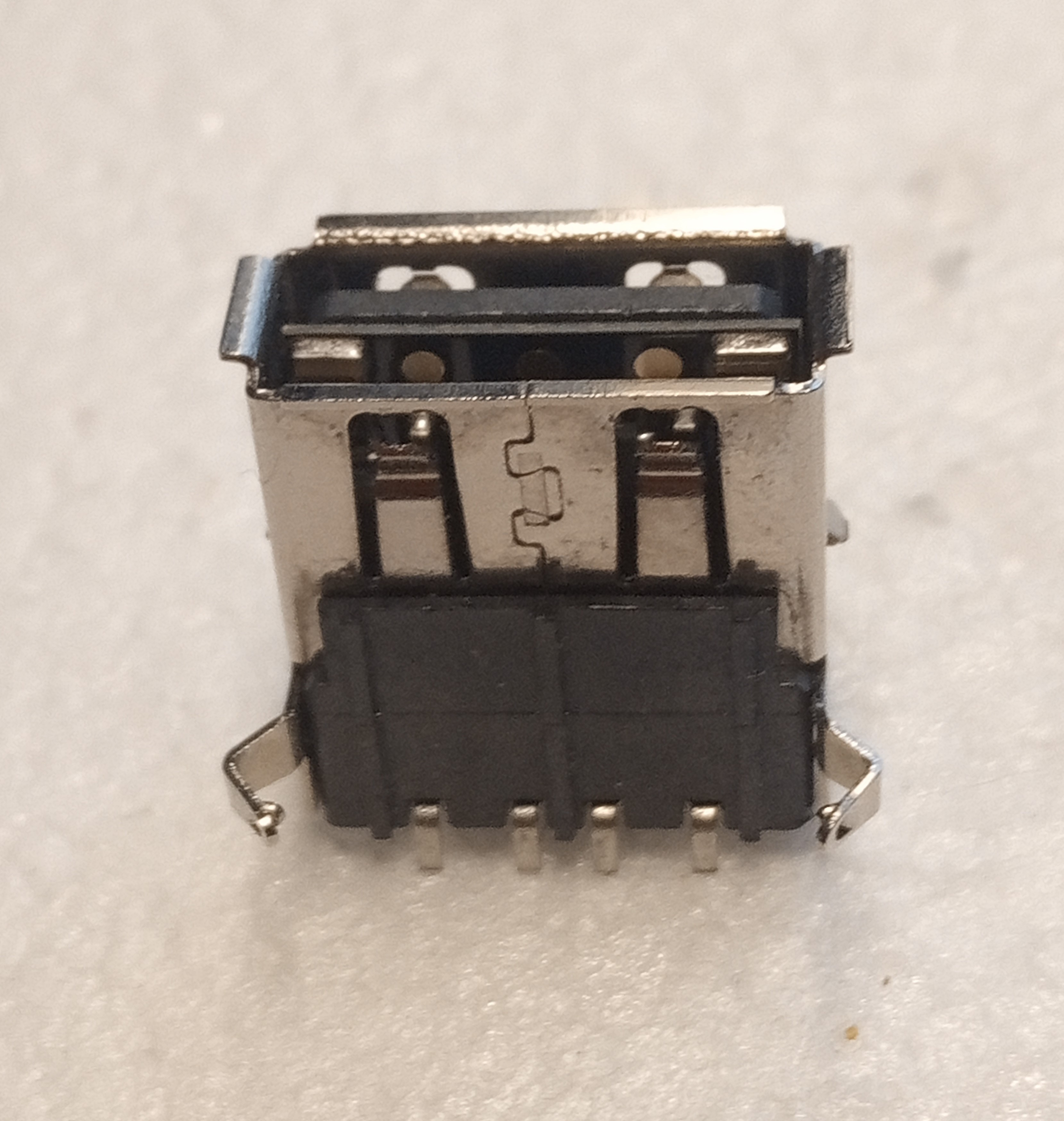

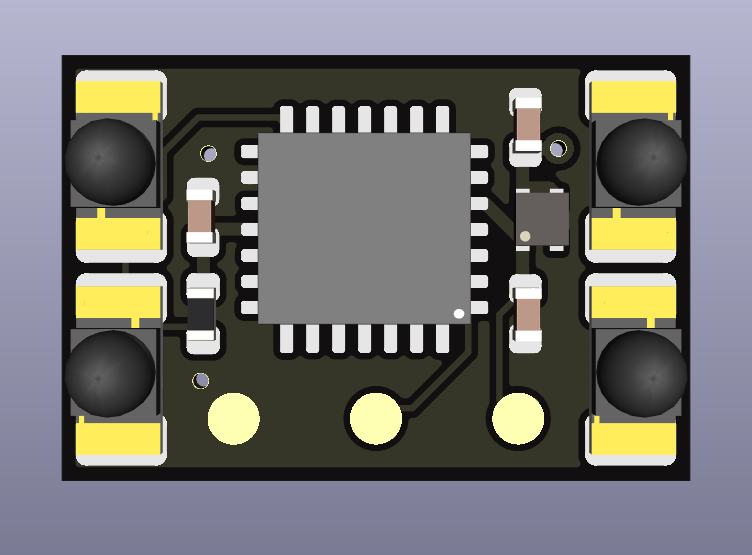

The concept of Hidden HID was born after I noticed how much space was available inside the USB connector and wondered if it would be possible to hide a rubber ducky completely inside it. With the increasing miniaturization of components, it was quite easy to design a basic USB enabled microcontroller circuit that fits inside the 2.5mm available. The device is kept in place using the phototransistors, which at 1.8mm tall are large enough to act as spacer elements. Added to the 0.4mm PCB, the resulting total thickness is 2.2mm, which fits snugly but comfortably inside the USB port.

Once inserted, it can be removed again by inserting any thin plastic tool into the port and pulling on the phototransistors. I use a plastic tweezer that I broke in half :)

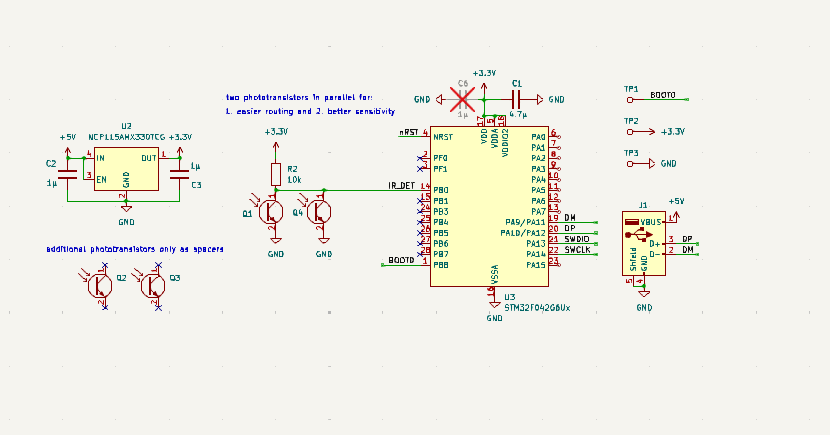

Circuit

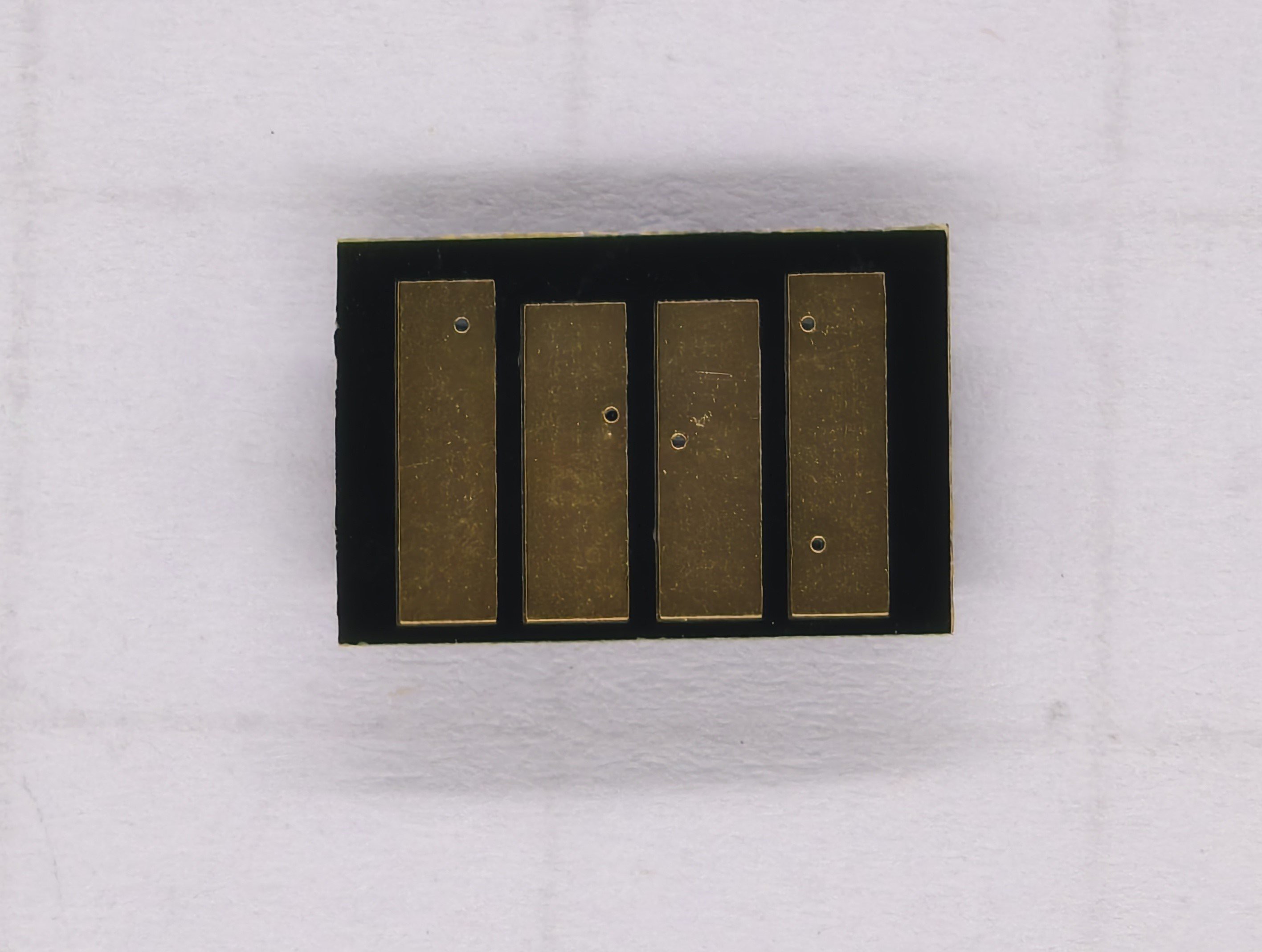

PCB

Frustratingly, I have not been able to find a good alternative phototransistor that fulfils the height requirements while allowing normal automated assembly.