The big need has been a cord lock for sandals. Lions pondered how to do it for years. Fortunately, it doesn't have to be temporary.

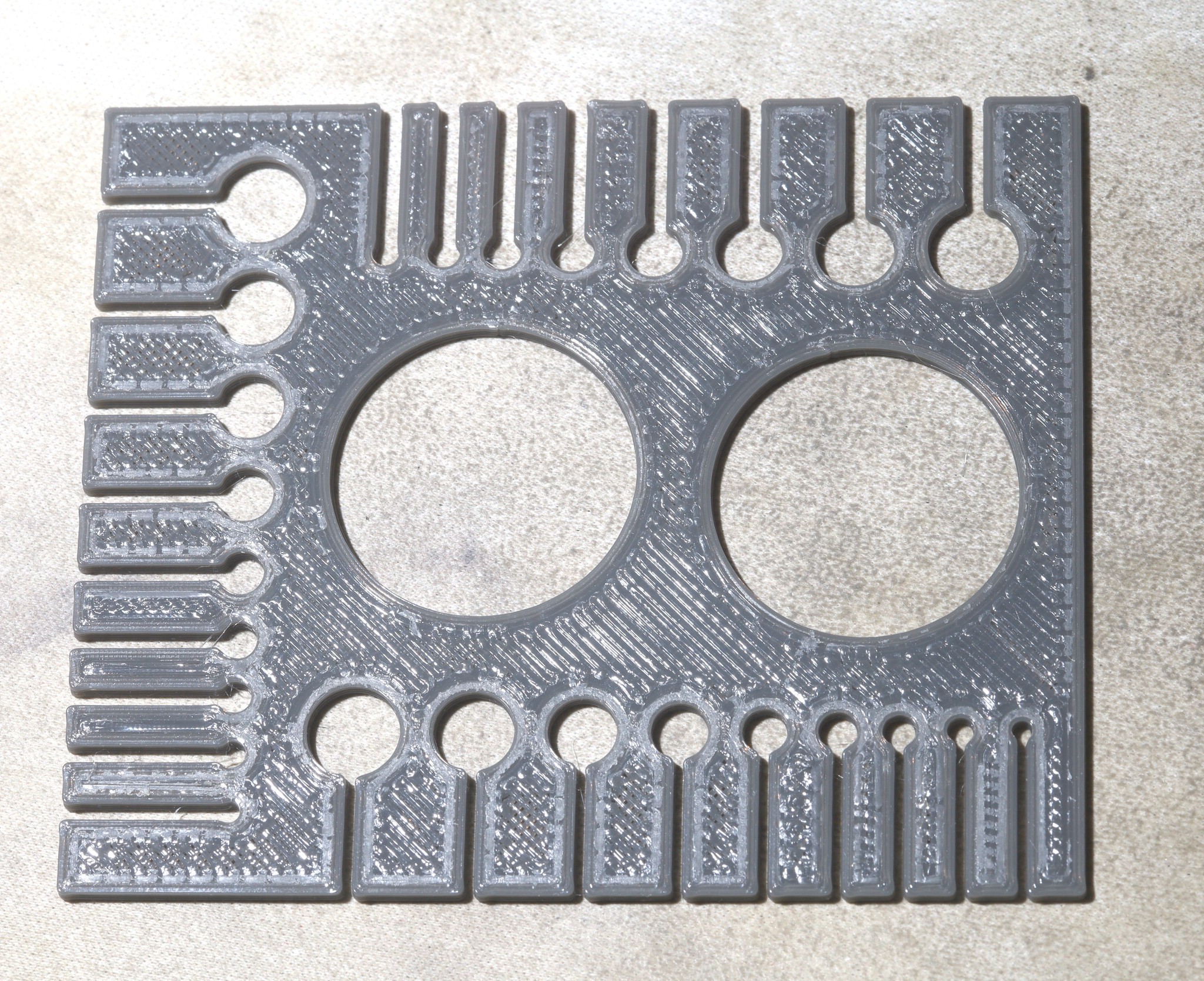

The journey began with a measuring template to determine the ID & the opening size. That would eliminate the lengthy trial & error of printing test pieces. Helas, there are too many combinations of opening size & ID. Only a selection of the most common sizes is possible. After a few tries, the right way was to make separate templates of all hole sizes for 1 opening size. They should all be in a single row to conserve material. 2 templates could interlock to test a permanent design.

The sandal cord lock would be 2 triangle panels, welded together. A 1st attempt showed the template to be very approximate. It was brutally hard & inaccurate to assemble 3 strings in a single panel. It would be a lot easier as 6 separate pieces which got welded onto a common pin. The problem is chafing from all those pinch points. A stack of 6 pieces would be quite a tower.

Another idea is using 3 separate pieces to provide grip to the strings & 1 loose fitting piece to just bind the strings together. It would be easy to install the thing which connected to all 3 strings & hard to install the things which connected to 1 string.

This turned out just as hard as 6 difficult attachment points. Anything which is simultaneously connected to 3 strings is going to be hard to install, no matter what. The multi stranded laces are also hard to install. This still didn't provide enough grip to the thong.

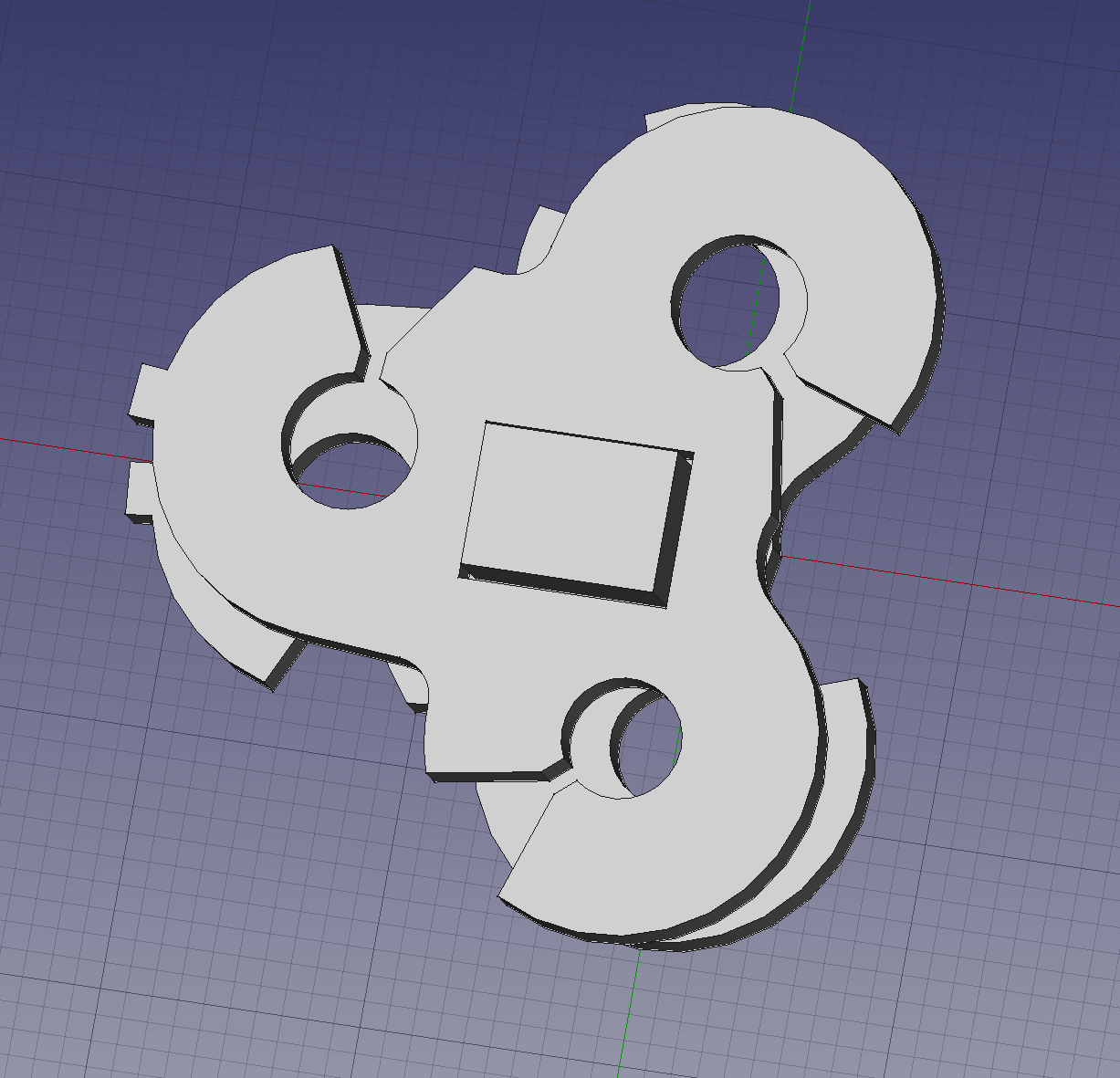

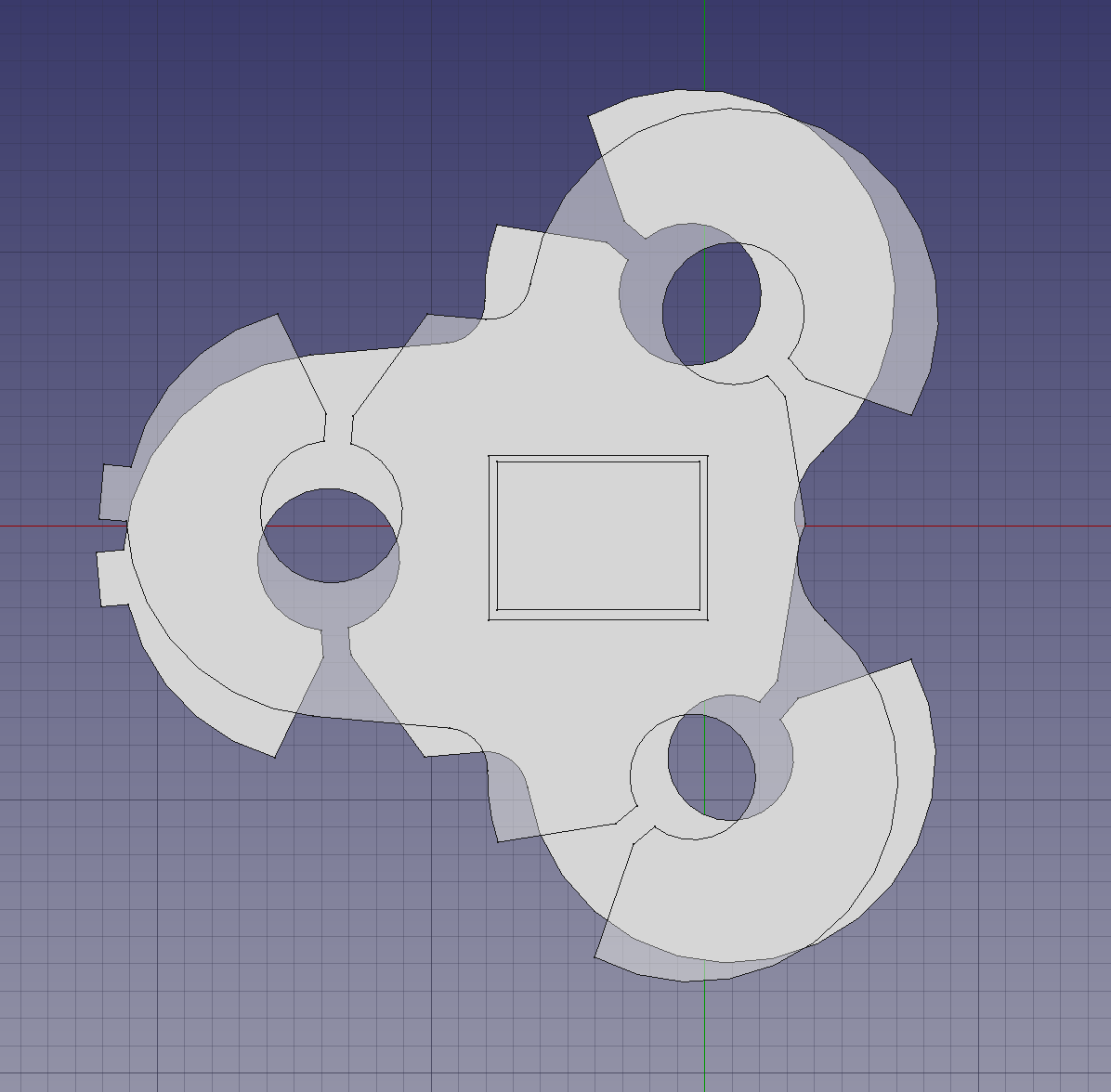

Another idea is 2 loose fitting triangles which are staggered to create grip. There could be slits instead of holes.

Best results were coming from this staggered design. Installing the string was just always going to be hard & require chinese manufacturing skills.

Best results come from printing mirror images to ensure the bed side faces out. A lot of tweeking & printing is required to get the right grip. All that really matters is the grip beating the commercial solution.

There's a lot to hate about it. There isn't enough material left after cutting out the fiducial. The rivet would be expected to deform over time.

1st completed sandals with the printed cord lock.

No welding was required so far.

5 miles later, they were firing on all 33 raptors. No chafing issues, better grip than commercial solutions, still possible to adjust in the field. It remanes to be seen how well the sting wears.

It takes a lot of fiddling in the CAD program to get the overlap just right. The 3 holes should have similar amounts of overlap.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.