So after the long dark teatime of the soul (aka pandemic restrictions) I finally came back to this in the 2nd half of 2024.

And I did a lot of re-thinking the whole project which lead to quite some changes.

watchface.

As notable in the project pic, you don't need 3 separate for the last 3 "digits" after the "V". The one LED for II (2) and one for I (1) will give you 0-3 with just 2 LEDs. After a while you might even note that the pair of XX follows the same rule as they are needed only to light up together, which would result in only 16 LEDs need in total. But you won't save much space since unless you invent a new "double-X" Letter.

Would I have come sooner to the later idea, I might have used the adafruit neopixel16 ring to get an even smaller 2nd prototype. Here is the comparison of the 3 pixelrings (sadly the 18 has a lot more space between the LEDs, which leaves it bigger than necessary:

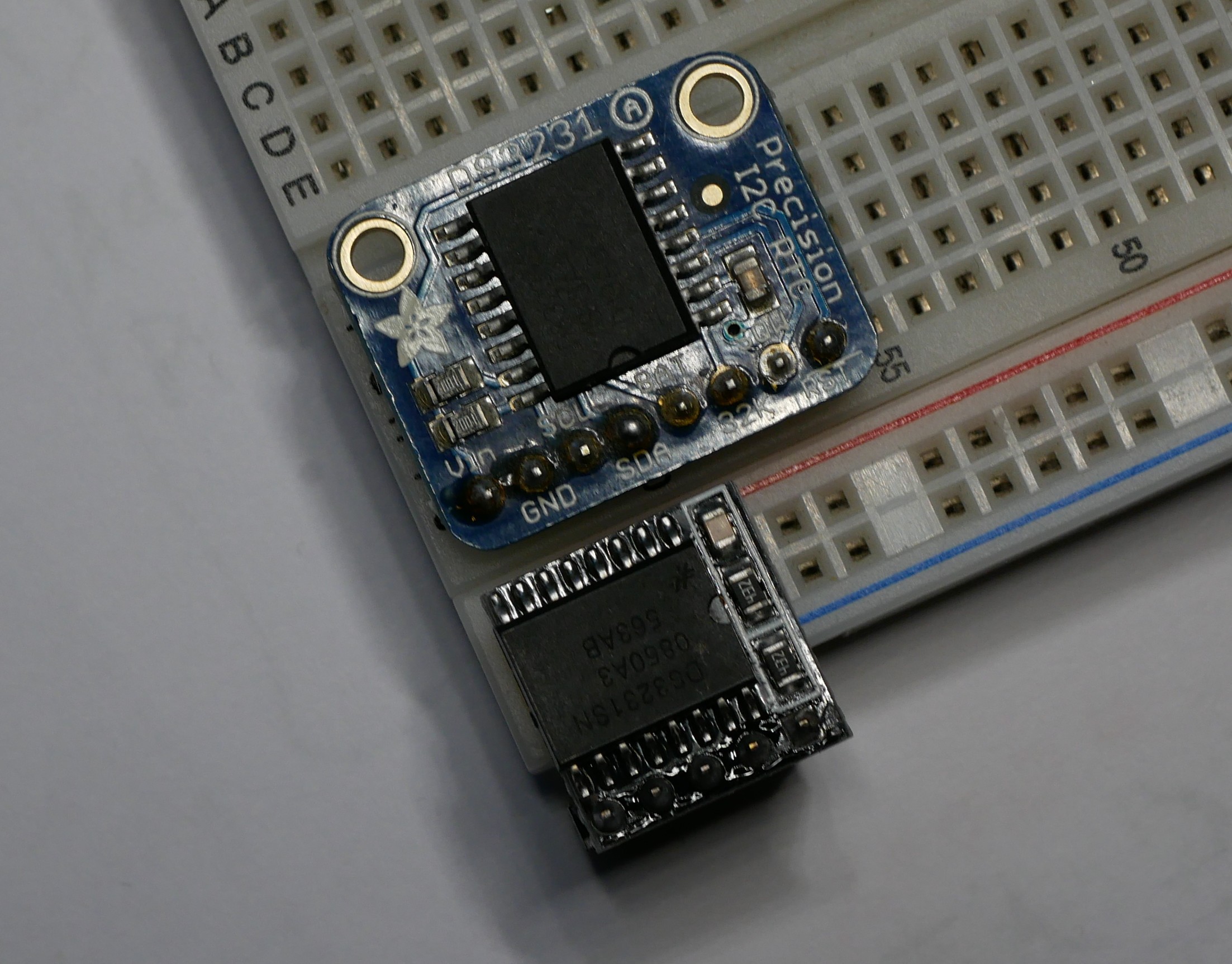

smaller RTC modul

The DS3231 is available in a SO8 package, but the SO16 seems to be much cheaper and I didn't find a module with a SO8 package. I did find a small one meant to be used as aPiHat. I have a preferred IC for the future, the mircocrystal RV-3032 or RV-3028, but there was no complete modul which was smaller than the PiHat with the DS3231, so I went for the PiHat for the prototype.

Size comparison of the DS3231 modules:

Power latching

I chose a circuit with MosFets this and the ability to have the power-on button double as an input while the circuit is powered on.

MCU/functions

adafruit trinket for size reasons, also I miss just one more GPIO.

In addition to the obvious power on, PWM for the pixelring, there is an LDR for sensing the ambient light and adjust the brightness of the LEDs accordingly. 2 pins for the I2C communication.

connector/charging

As there isn't much room to place an USB port sideways, I decided to use a magnetic connector on the back of the case. As there is now no risk of an standard USB plug being used, I placed the charging logic outside the watch. So the 5 PIN mag connector from adafruit works fine. GND, USBpower, LIPoly+ and 2 datalines for usb.

I was thinking about using one of the serial pads on the backside of the trinket as input to measure the voltage of the battery and all parts are placed, but that requires some adjustment in the general board setup, which I was reluctant to use in the first run.

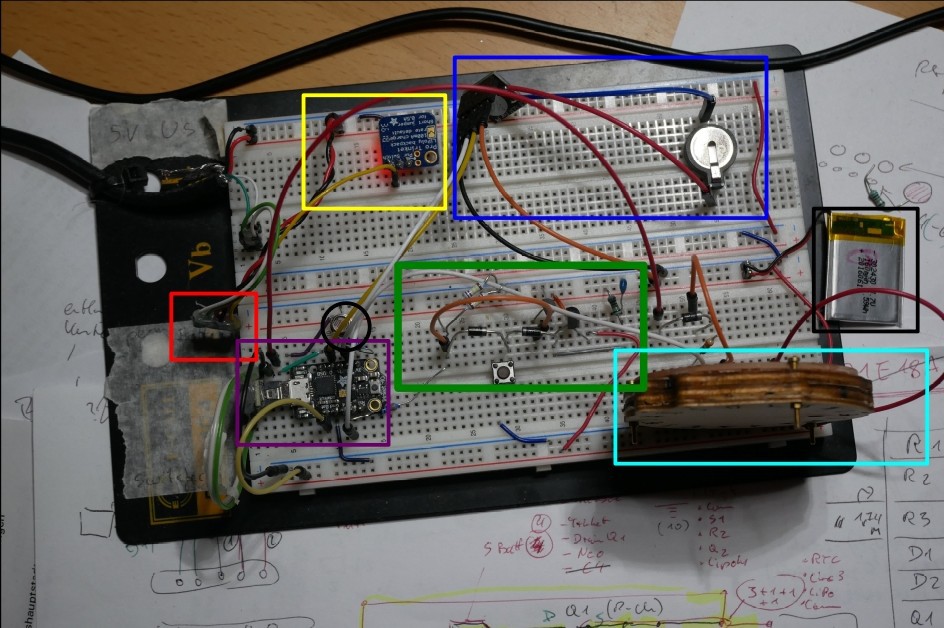

Here is a pic of the breadboard setup:

yellow: charging circuit

blue: RTC incl. backup battery

red: pin headers (simulate the future mag connector)

black circle: LDR

purple: Trinket

green: power latch

cyan: LED ring with laser mask

black: lipoly battery

That worked fine (I

even tested the voltage measure setup by using the pin of the LDR

mclien

mclien

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.