I've spent the last couple of months buried in motors.

I've been hunting for the perfect motor with a sweet spot of weight, power, and cost.

The sweet spot

- Torque: 10Nm+

- Size: smaller than 85mm diameter x 50mm thick

- Weight: under 400g

- Cost: under $150

Torque

The spider will have a whopping 24 motors!!! That's divided up into three motors in each of the eight legs. I'm assuming the robot will weigh between 20 - 30 lbs, so my back-of-the-napkin calculations say that each motor should have 4-6Nm of stall torque. I'm assuming the motors would need at least twice that to jump, plus a relatively high RPM.

These are all rough estimates. I've never built something like this before and welcome any feedback on my assumptions.

Size/Weight

To keep the robot's weight under 30 lbs, I need to keep the weight of each motor under 400g.

I also want to keep the motors as small as possible to keep the overall robot size manageable. The bigger the robot, the stronger the legs need to support it.

Cost

With 24 motors, the robot gets expensive fast. There are many sexy and expensive quasi-direct drive actuators on the market. But for my budget, $150 is expensive but workable.

The standout options

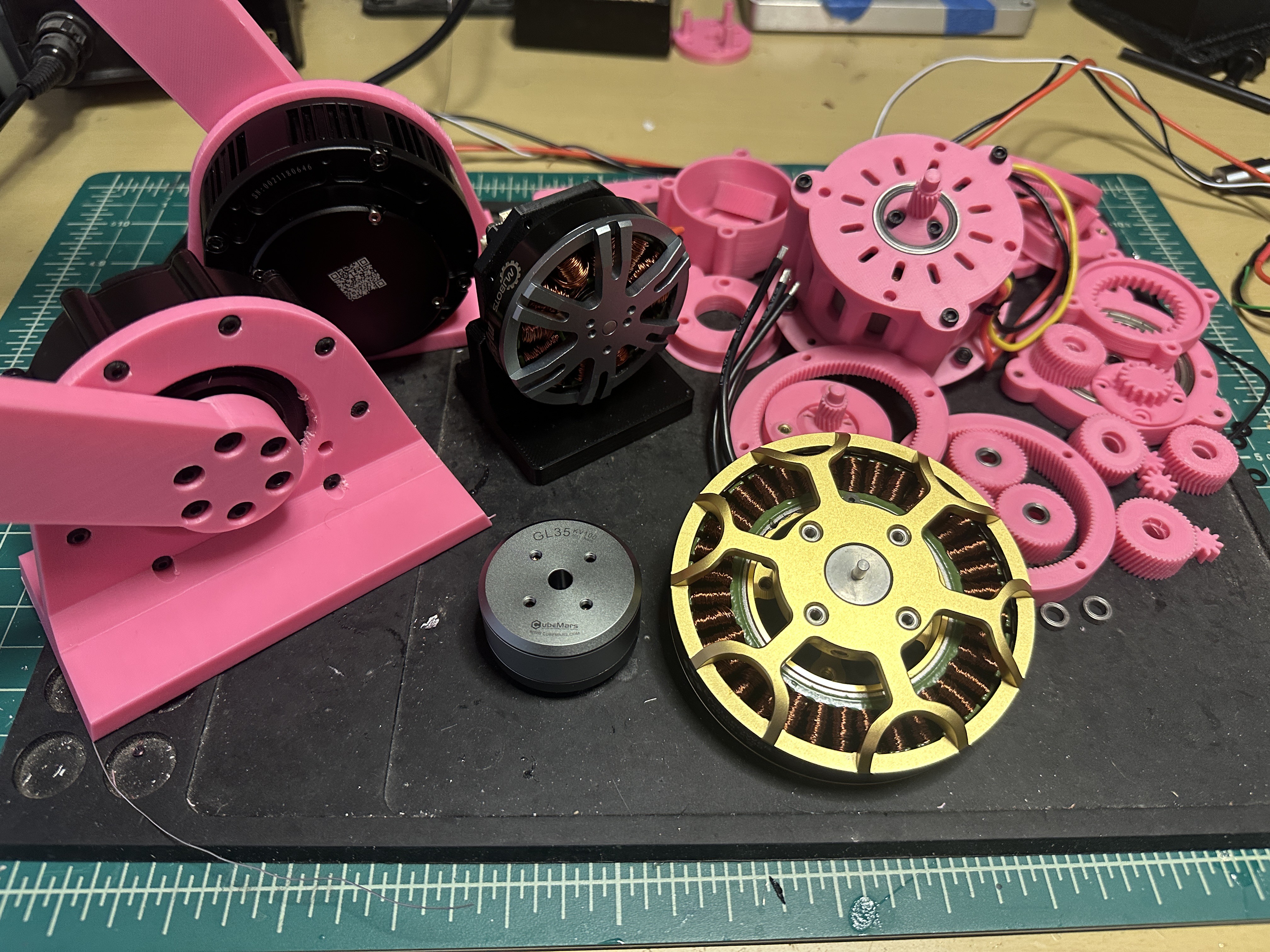

I started by looking at homebrew designs, like building a motor + planetary gearbox around a frameless motor. After many iterations, the results were good, but the cost, torque, and weight did not match that of off-the-shelf quasi-direct drive actuators (more on those, below).

Then I looked into capstan drive systems with motors like the GL35 and the eagle power 8308. These either didn't provide comparable RPM and torque to off-the-shelf quasi-direct drive actuators and would be too big and cumbersome for an eight-legged robot.

At each stage, I kept coming back to these off-the-shelf quasi-direct drive actuators:

The quasi-direct drive actuators

Off-the-shelf quasi-direct drive actuators have built-in gear reductions between 8:1 and 10:1, giving them high torque and responsive RPM. These actuators usually put the planetary gearbox inside the motor stator, keeping the overall motor compact.

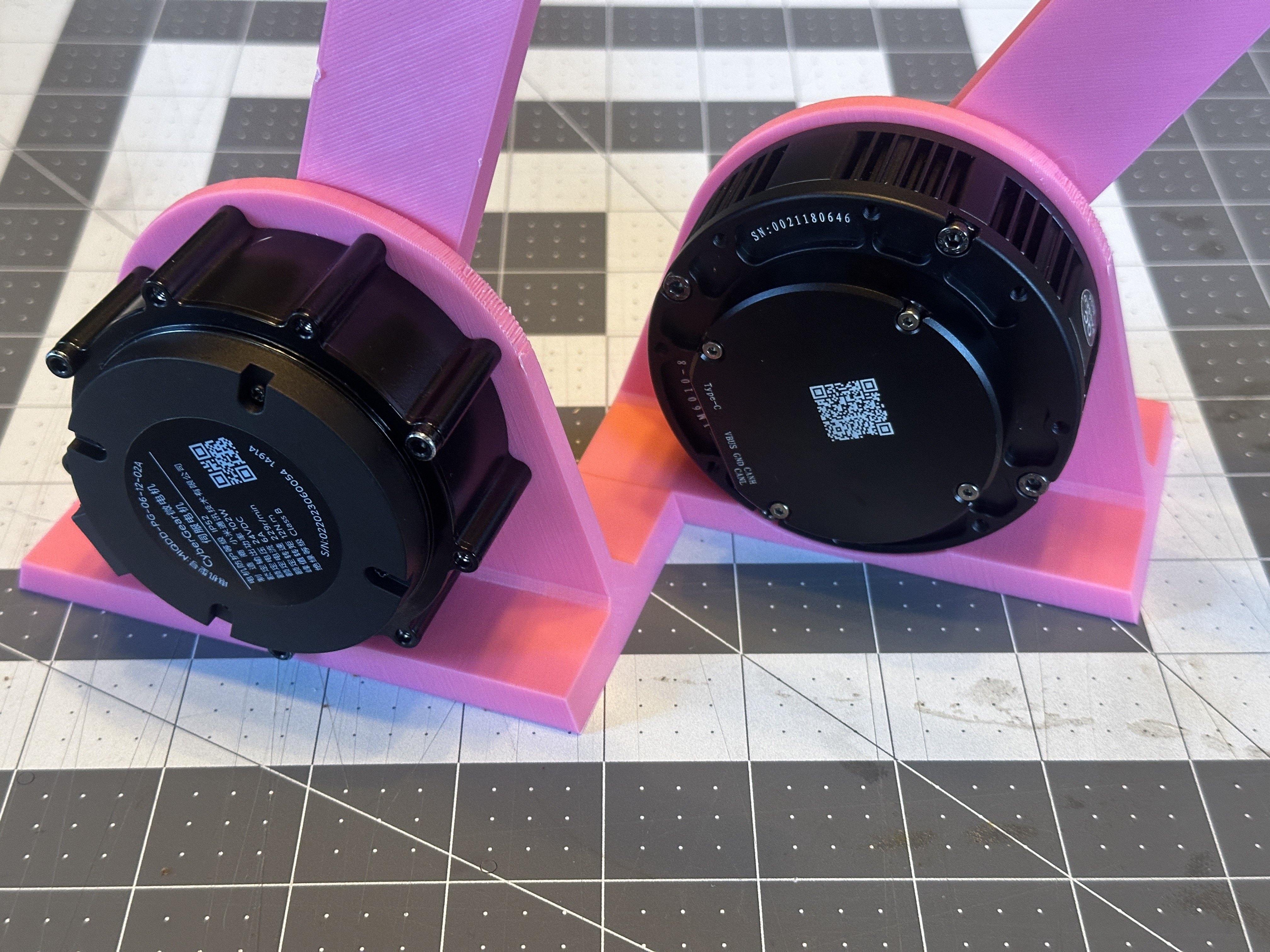

But this all comes for a price, and many of these actuators are beyond my budget. However, I found two that fell right into the sweet spot of price and stats: the Steadywin GIM6010-8 and the Xiaomi CyberGear.

Now, to choose which one to use.

In the next post, I'll go into greater detail, but here's the high-level comparison:

- Size: similar size to each other

- Torque: similar stall torque (11 - 12Nm).

- Weight: CyberGear is nearly 70g lighter than the GIM6010-8.

- Torque per Amp: CyberGear has nearly twice the torque per amp (torque constant) at 0.87Nm/A. The torque constant of the GIM6010-8 motor is 0.47Nm/A

- Cost: GIM6010 is a little cheaper as a complete unit and significantly cheaper ($50) when purchased without a driver (i.e. bring your own driver).

- Driver: The GIM6010 uses an ODrive 3.6 compatible clone, which is easily swapped out. The CyberGear has a proprietary driver with minimal documentation and features.

See the tests I put these through in my next post.

Jeremy

Jeremy

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.