This project was inspired by the book of Sten Odenwald 'Exploring Space Weather with DIY Magnetometers'.

The book presents several simple DIY ways of registering the changes in geomagnetic field.

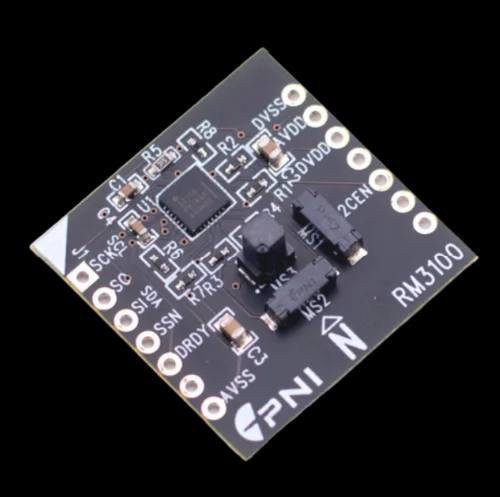

Among them there is a chapter describing how to use a sensitive magnetometer board RM3100 connected to Arduino UNO micro-controller. Magnetometer was developed by PNI Sensor Corporation; there is a detailed guide from PNI for interfacing this sensor with Arduino platform; the guide is available at https://github.com/hnguy169/RM3100-Arduino/tree/main

For the reference, here is RM3100 specification from PNI:

https://www.tri-m.com/products/pni/RM3100-User-Manual.pdf

Arduino-based construction described in the book is very basic; so I decided to try this sensor board myself having in mind to produce somewhat more elaborated design; when working on this small project I had a lot of fun and also learned some new tricks. So I think it might be worth sharing my experience with the community of fellow makers and also to express a gratitude to Sten Odenwald for sharing with us such an inspirational piece of his own knowledge and experience.

So below are the main features of my implementation of Arduino-based magnetometer:

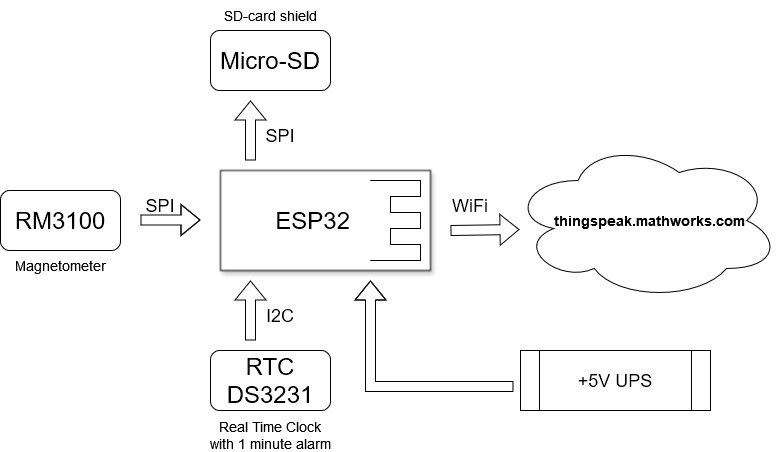

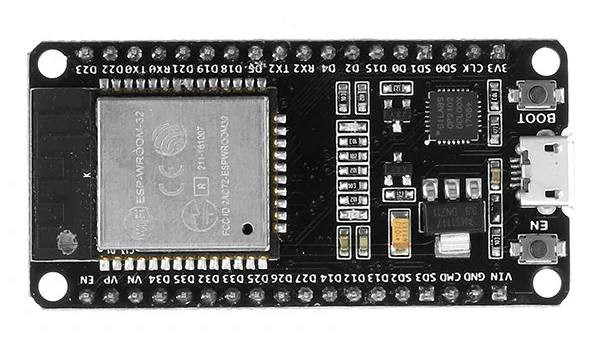

1. ESP32 board as a main controller(MCU). It allows to overcome RAM restrictions of most Arduino boards; it is also capable of connecting to Internet with WiFi.

2. Magnetometer RM3100 communicates with MCU through SPI interface

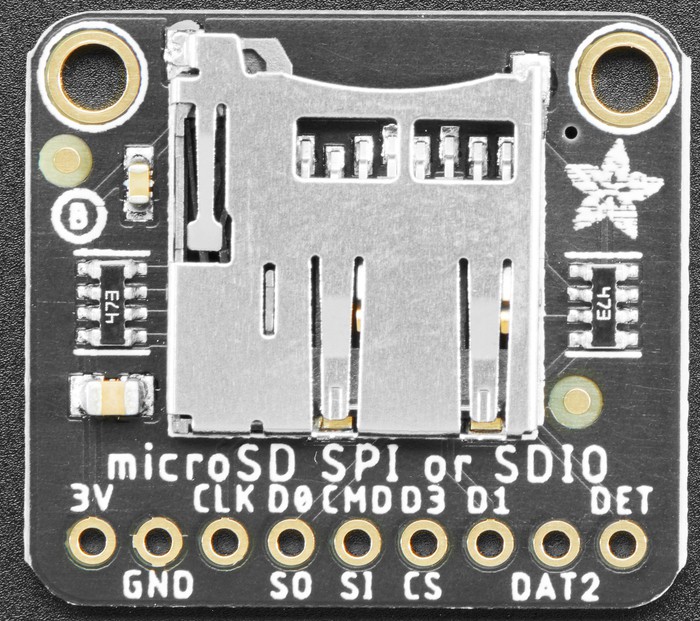

3. SD-card board is attached to MCU (SPI interface as well) and every minute averaged magnetometer reading alone with exact timestamp is stored on micro-SD card in .csv file. Upon every power-on MCU creates automatically a new file on SD with unique name.

SD card can be extracted during the working cycle without stopping the measurements; if SD card is re-inserted, a new file with timestamp is created on the card and data is placed into the new file;

4. There is a simple two-color LED indicator of MCU functioning: permanent red while connecting to WiFi router/modem, blinking red if SD card is missing, blinking green when data processing is normal.

5. MCU reads magnetometer data based on the state of 'data ready' pin of RM3100; magnetometer "cycle counts" parameter is set to 400. (I found that setting this parameter to 800 does not increase sensitivity but greatly increase the noise level. )

MCU reads 3 components of magnetic field and calculates the total value as

After that it calculates moving average value Bavg

6. There is a high precision RTC (real time clock) board attached to MCU via I2C interface. RTC uses DS3231 chip with temperature compensation. RTC board provides a timestamp for creating a data file on SD and also for each magnetometer measurement; it also generates an alert (changes the status of designated pin) every 60 seconds; when this alert occurs the current value of Bavg is recorded on SD along with current timestamp.

7. Besides recording data on SD card, the measurements are also sent to the internet to IoT platform ThingSpeak.com.

WiFI connection credentials and ThingSpeak channel API write key are stored on SD and can be easily adjusted;

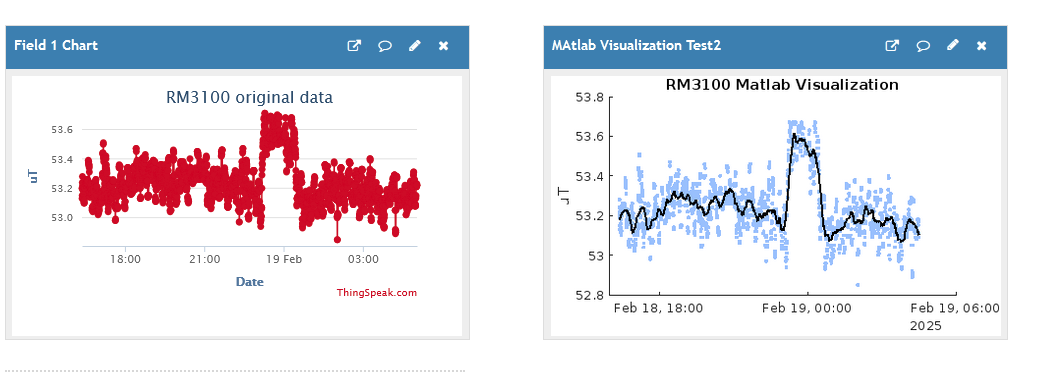

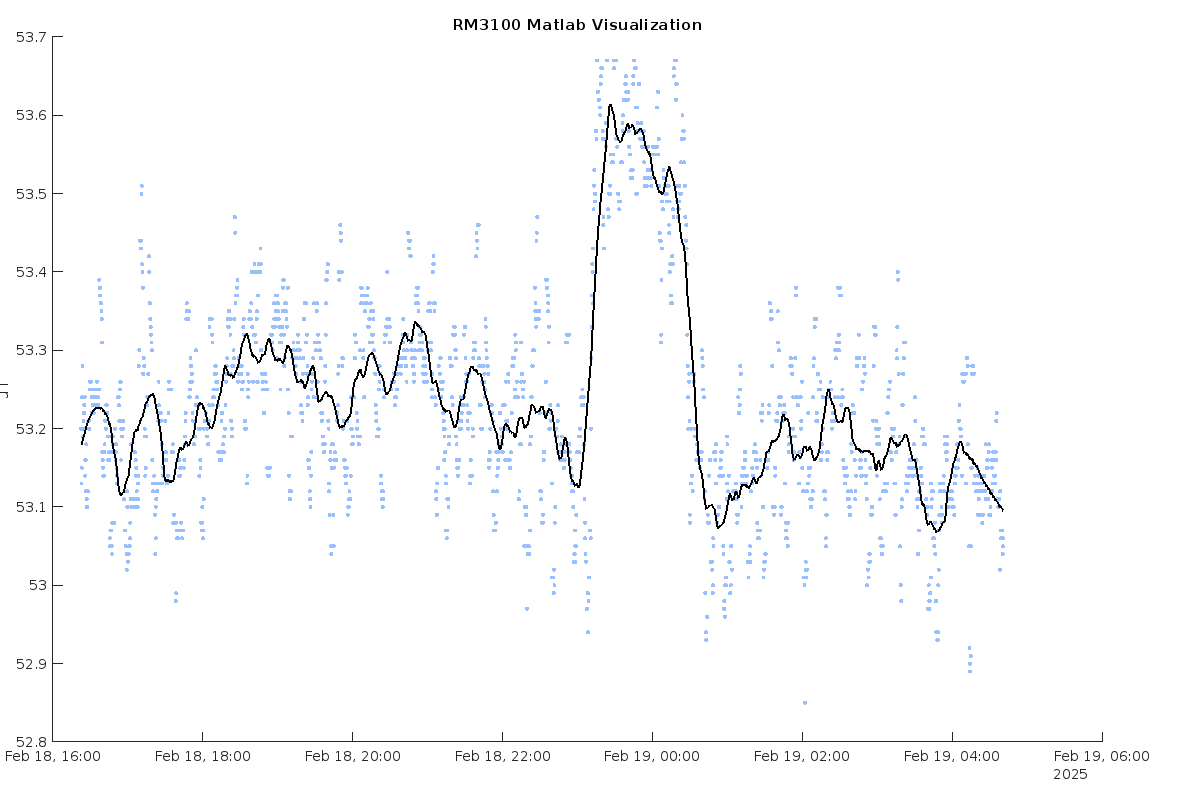

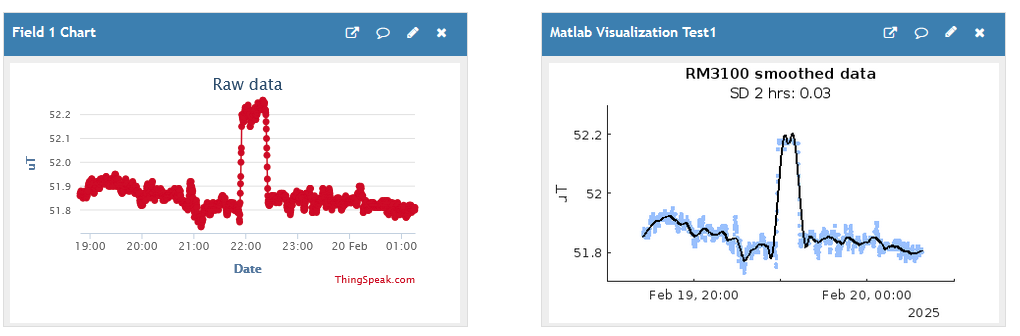

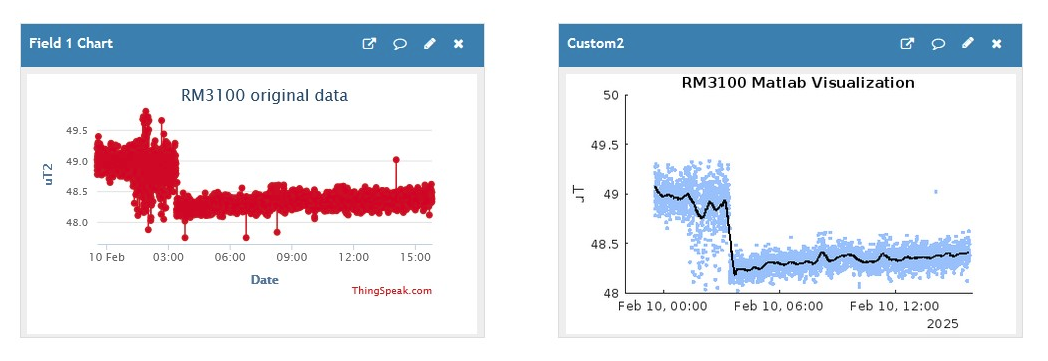

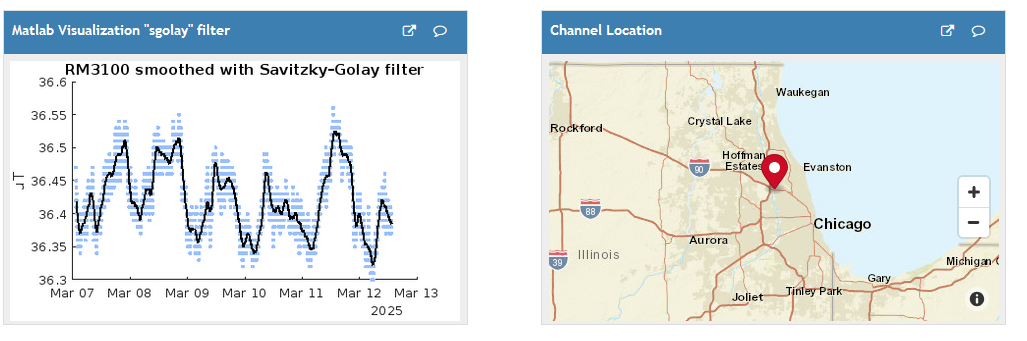

Using this data MCU connects to my local cable modem/router (Comcast) through WiFi; after connection with network is established it sends every minute a http request with Bavg value to api.thingspeak.com to my free account. This account has a public channel where the data is visualized as a time series plot. ThingSpeak.com provides only basic visualization, but it also offers to utilize Matlab Visualization application for more sophisticated processing of incoming data.

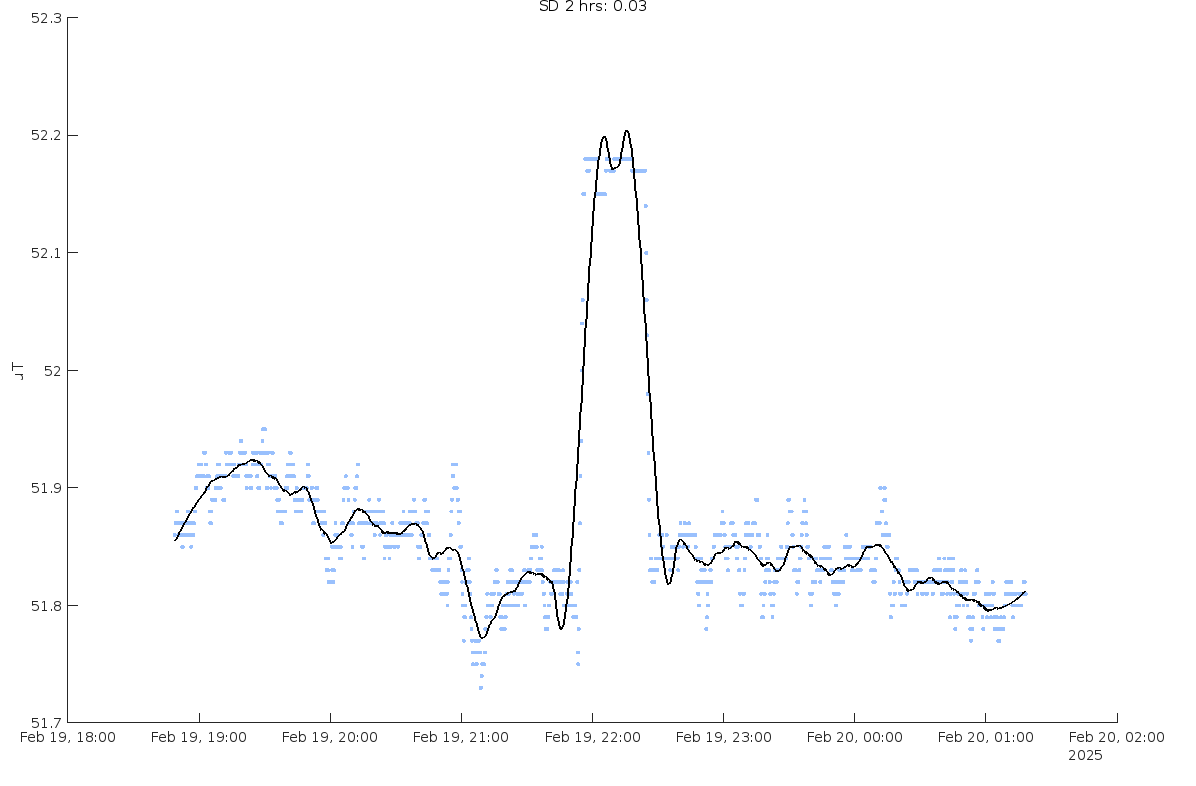

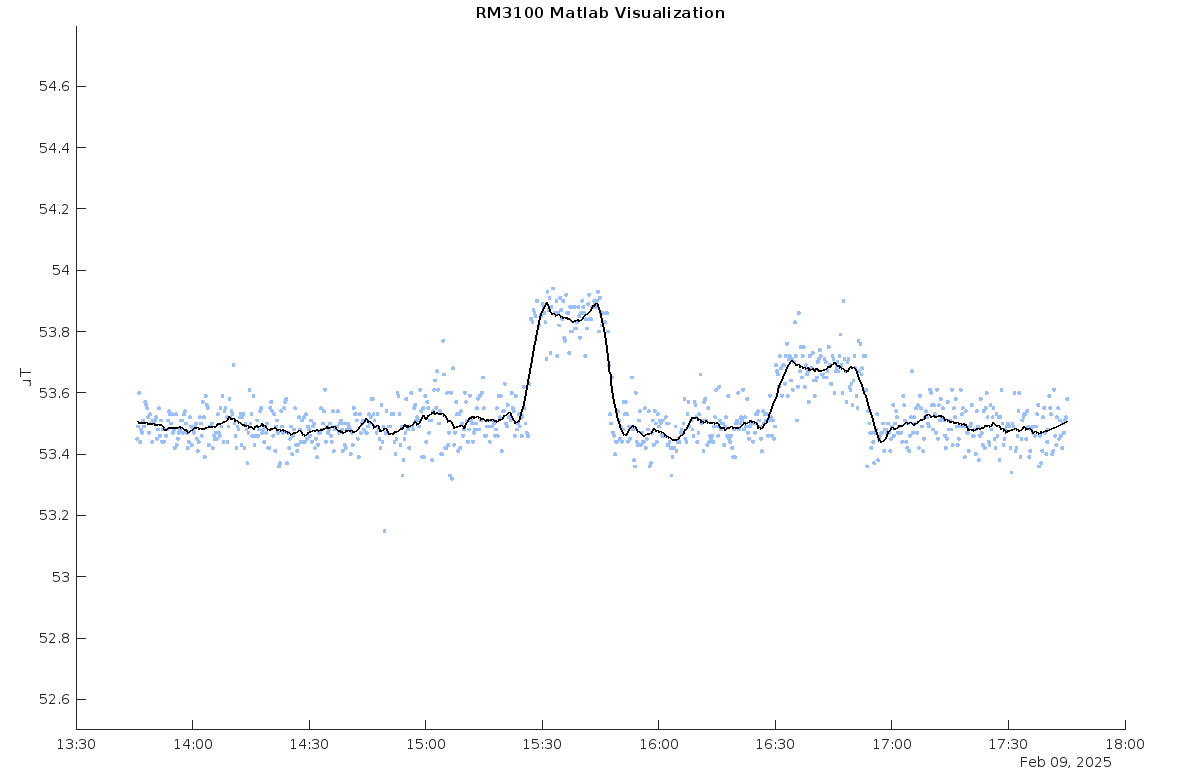

So I made a simple template-based program for Matlab app: it implements Savitzky–Golay filtering of incoming data and displays the result as a smooth curve superimposed over the original data points.

Here is an example of ThingSpeak visualization of magnetometer data:

I also decided to insure the stability of power supply for project boards, so I attached a battery shield board with a single 18650 element; this board is connected to wall USB +5V adapter, and ESP32 along with add-ons is powered from this 'UPS' unit: in normal mode it keeps 18650 charged and produces +5V power output; in case of external power interruption it still generates output voltage until 18650 battery is depleted; by my experience it can provide nearly 10 hours of standalone power supply.

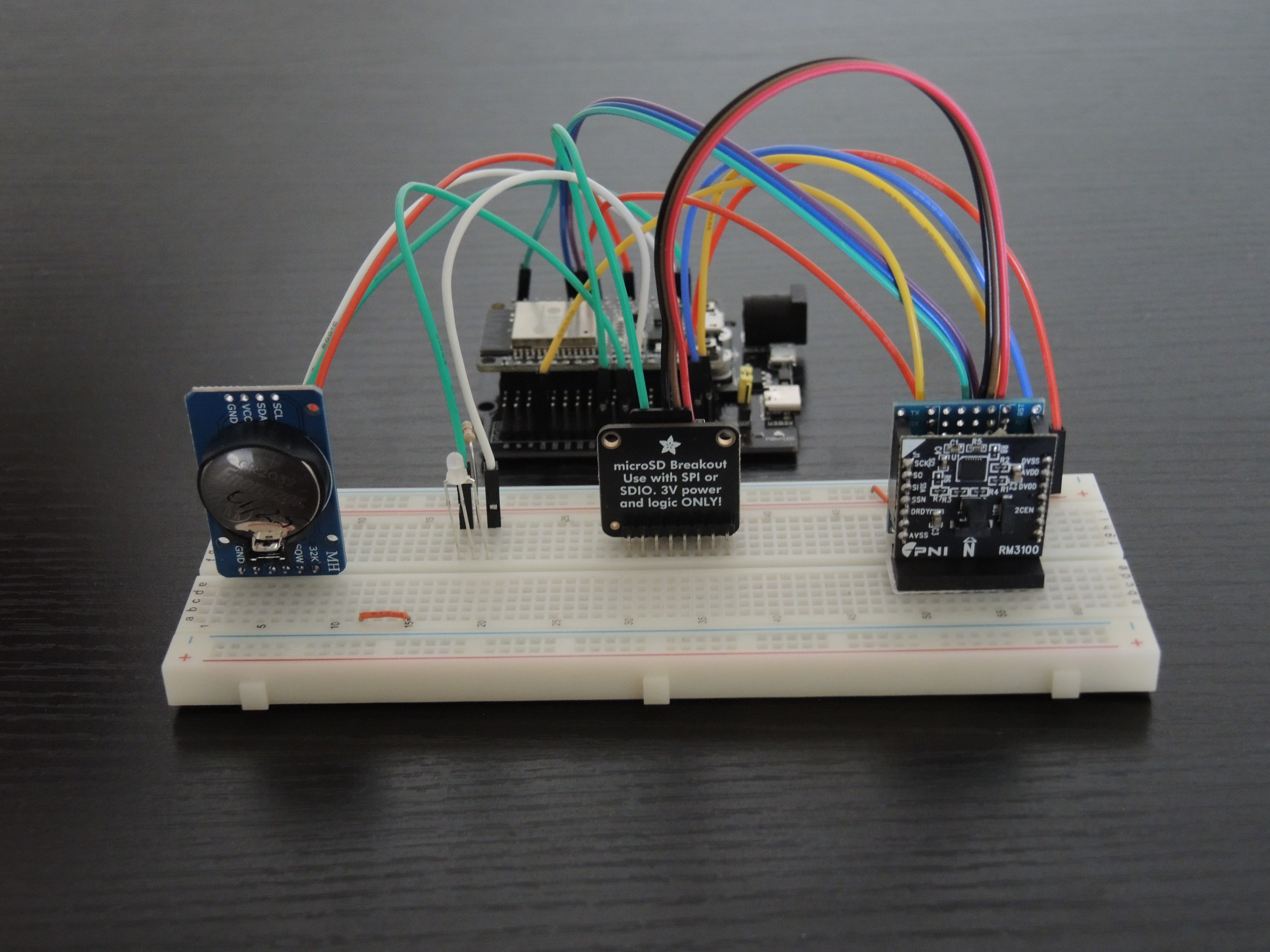

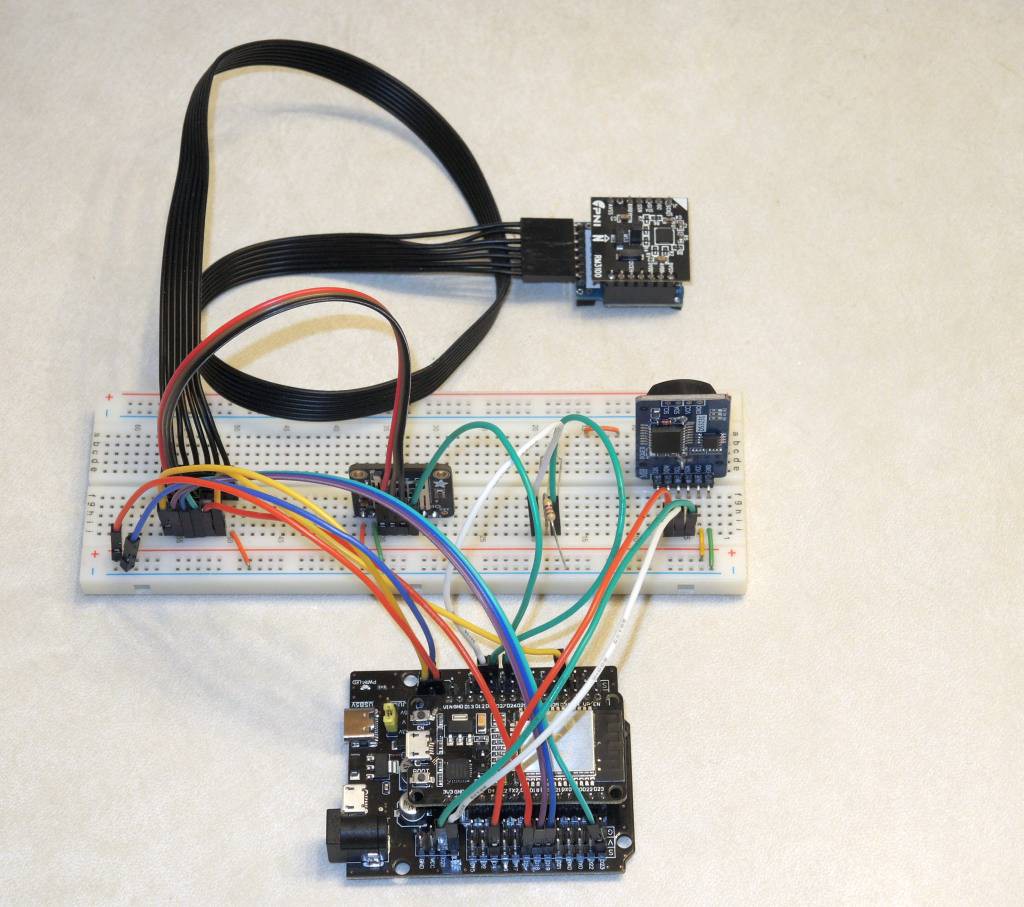

Here is a diagram of my project assembled:

PARTS AND WIRING

ESP32 board - ESP-WROOM-32 DEVKIT V1

For convenience MCU mounted on expansion board:

I used two versions of RM3100 boards that are available:

'Board 1':

'Board 2'

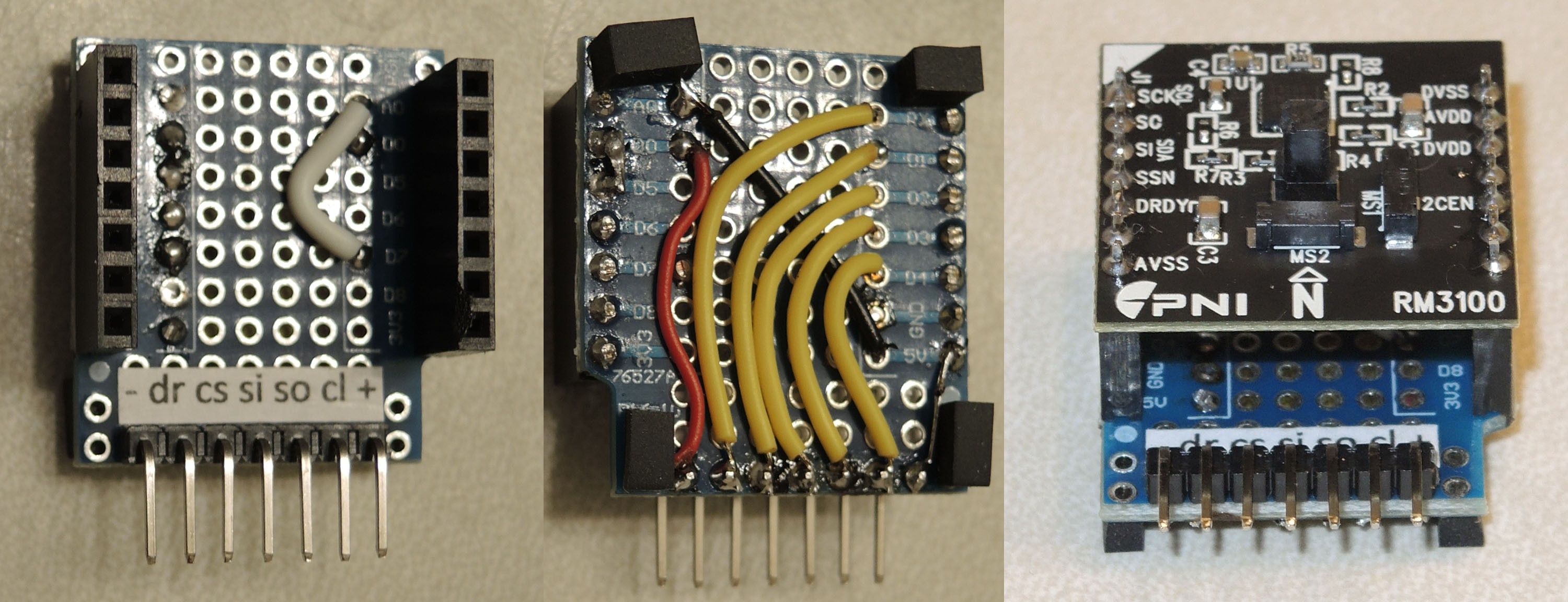

I made a simple 'adapter' for RM3100 breakout:

I made a simple 'adapter' for RM3100 breakout:

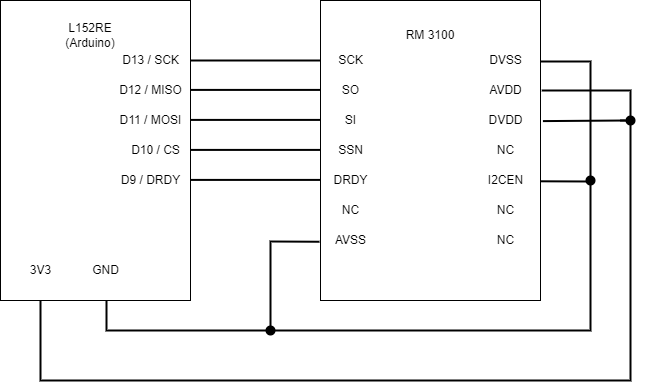

RM3100 to ESP32 wiring:

Per diagram from PNI RM3100 Arduino Quick Guide https://github.com/BrownSpaceEngineering/RM3100-Magnetometer/blob/main/RM3100%20Arduino%20Quick%20Guide.pdf:

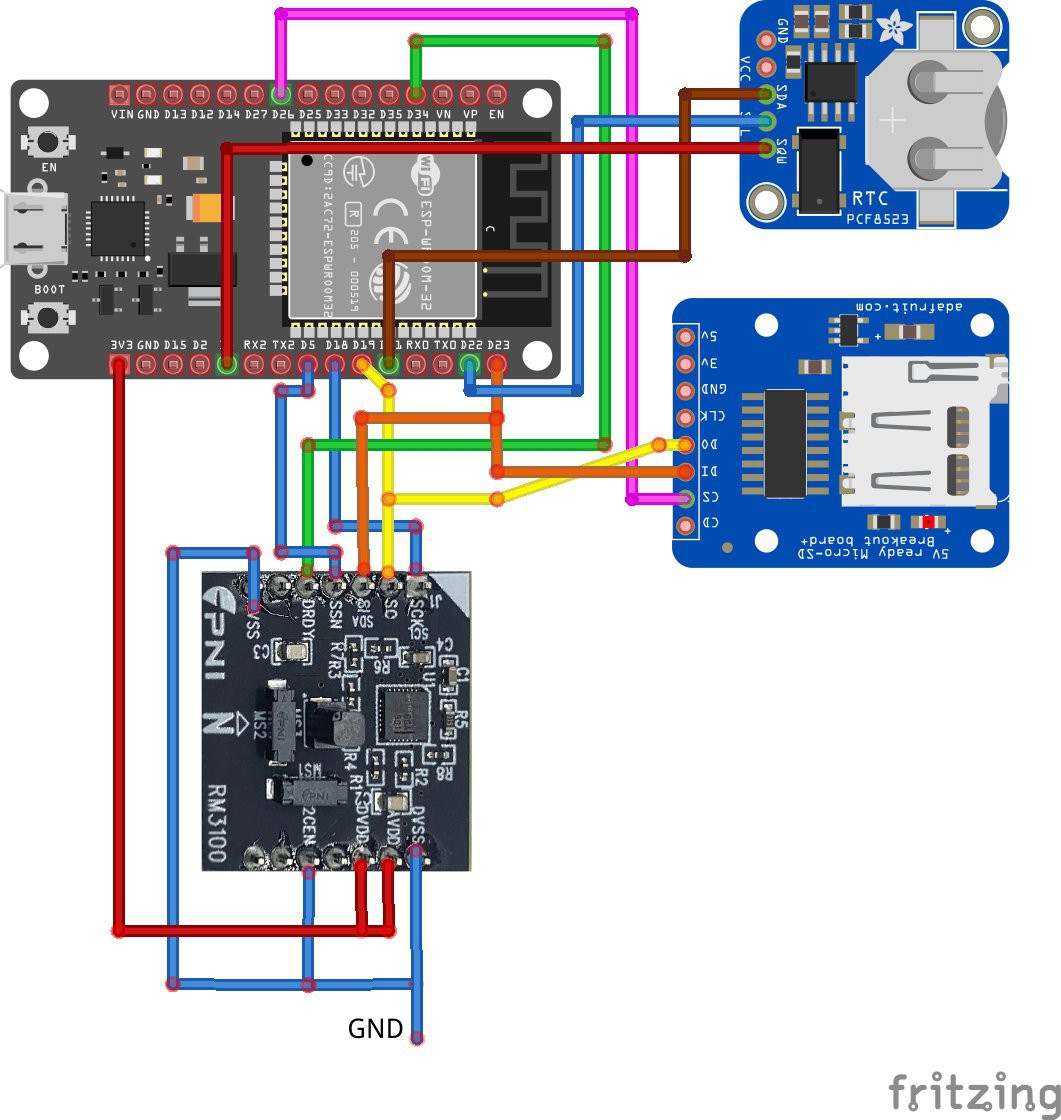

Project wiring - Fritzing diagram:

RM3100 CS - ESP32 Pin D5

RM3100 DRDY - ESP32 Pin D34

RM3100 SI - ESP32 Pin D23

RM3100 SO - ESP32 Pin D19

RM3100 SCK - ESP32 Pin D18

RM3100 AVSS, DVSS, I2CEN - ESP32 GND

RM3100 AVDD, DVDD - ESP32 +3.3V

SD breakout board to ESP32 wiring:

Shares SPI bus with RM3100, different CS pin

SD card CS - ESP32 Pin D26

SD card SI - ESP32 Pin D23

SD card SO - ESP32 Pin D19

SD card SCK - ESP32 Pin D18

SD 3V - ESP32 +5V*

*by some reason when powered from 3.3v works less stable, fails to initialize quite often

RTC SCL - ESP32 Pin D22

RTC SDA - ESP Pin D21

RTC SQW (alarm pin) - ESP32 Pin D4

Powered from ESP32 +5V

"UPS" board:

The project assembly:

For experiments with magnetometer orientation and easy placement I also made a flexible connecting cable from flat silicon 26AWG ribbon:

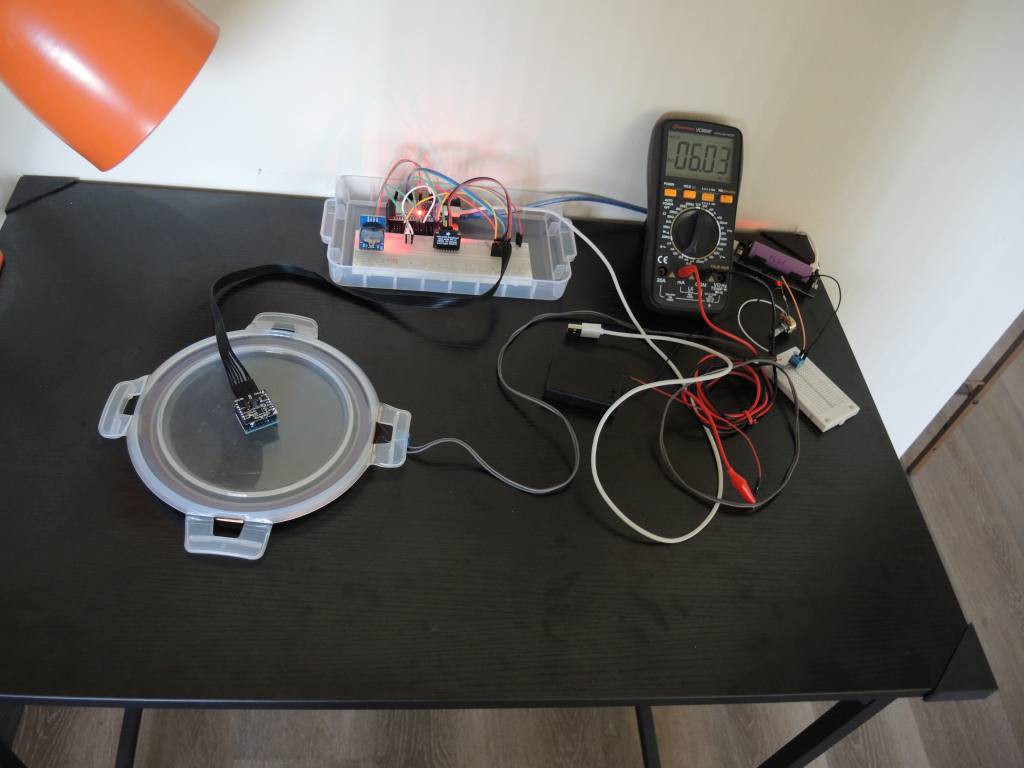

I also conducted some experiments for verifying magnetometer sensitivity and estimating its noise level. For this I made a primitive 'Helmholtz coil' using a plastic lid from kitchen container similar to this one:

My coil has 10 turns of AWG35 copper wire and a diameter of 17.2 cm:

PNI document claims that RM3100 noise level at Cycle Count 200 is about 15 nT. This is definitely over-optimistic statement; by my experiments even at Cycle Count 400 the noise level is at best 100 nT ; sometime noise level spontaneously increases to 300 nT and returns to lower level after power cycling:

Here is the research from UK Liverpool University dedicated to estimating RM3100 characteristics.

It shows that without very serious shielding the noise level of RM3100 is in the range of ~160-200 nT with SD value of 0.03uT

When shielding with multi-layered container and 'copper room' is provided, noise decreases to ~20nT which is close to official specification data (15nT). If we need to detect geomagnetic events, no shielding can be used; so this means that in regular, common industrial environment without shielding the sensor can reliable detect field deviations starting from 150-200 nT. This is consistent with my results: I observed reliable readings change when external field of ~200nT was applied by Helmholtz coil; but field's intensity change below 100nT hardly can be detected reliably.

This limitation can be probably overcame by locating a sensor at some environment essentially free from industrial magnetic fields, like some rural area, far from any industrial and electronic activity;

Measurements

Two types of measurements were conducted:

1. short-term recordings to determine sensor normal noise level and sensitivity. Normally, 3-5 hours.

2. Long term data acquisitions attempting to register geomagnetic events.

For the first type of experiments sketch ESP32_RM3100_NOISE_AND_SENSITIVITY was used (see attached files).

I also used simplified setup - just ESP32 board connected to sensor via SPI, no SD card and no RTC board:

Sensor was placed in the center of coil; for testing a sensitivity I energized the coil form 3AAA batteries and maintained a current of 6 mA. Here is the working moment of measurements. Here I use a full project setup with SD-card and attached RTC board; but for this type of measurements neither of them is used.

Magnetic field on the central axis of a flat circular coil is calculated as (see here f.e.)

μ0 = 4π × 10−7 is the vacuum permeability, h is an adjustment for the distance 'x' between flat coil center and measurement point:

Sensor was polled every 15 seconds, readings were used to calculate

B value was submitted to RunningAverage procedure in Arduino sketch with moving window of 10 readings. Current average value of B was sent every 15 seconds to ThingSpeak IoT server. Besides standard ThinkSpeak line chart I also added a Matlab Visulaization chart that combines scatter plot of raw data and a plot of Savitzky–Golay filtered curve with a characteristic factor of 160. Matlab program code is attached below (see 'matlab_code.txt')

Results of noise and sensitivity measurements

Here are plots of 'Board 2' sensor data for 12 hours; in the middle we can see data increase when the coil was activated for 80 minutes.

Standard Deviation of first 6 hours (prior to coil activation) is equal to 0.094;

Visually I would estimate the noise level (peak to peak) as ~0.1 - 0.2 uT. Coil activation results in readings increase by ~0.4 uT which matches calculated value (above).

Here is smoothed data in more details:

Similar data for the another sensor board ('Board 1'):

Similar data for the another sensor board ('Board 1'):

Noise level for this sensor board is definitely lower, probably in the range on 50-100nT peak-to-peak; accordingly, SD value for initial interval of 2 hrs is 3 times smaller then for the other sensor board.

Noise level for this sensor board is definitely lower, probably in the range on 50-100nT peak-to-peak; accordingly, SD value for initial interval of 2 hrs is 3 times smaller then for the other sensor board.I also made some recordings when coil current was only 3 mA which theoretically produced a field of 200nT:

This is data obtained from sensor 'Board 2'.

This is data obtained from sensor 'Board 2'.Sensor boards instability

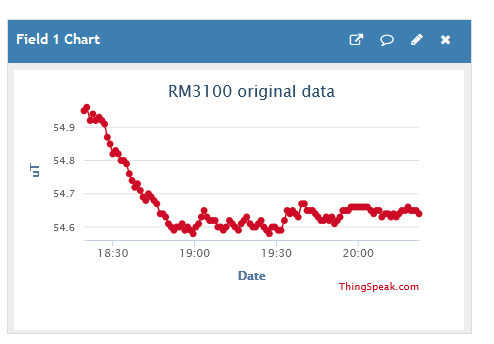

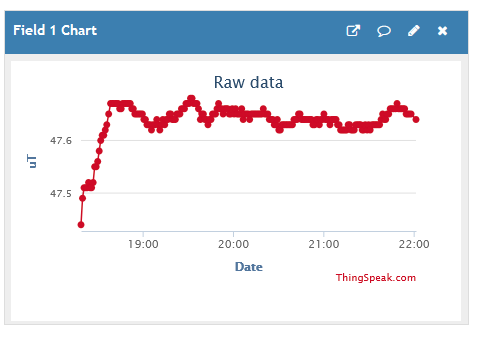

I observed in several cases a spontaneous noise change and value drifting of sensor readings.

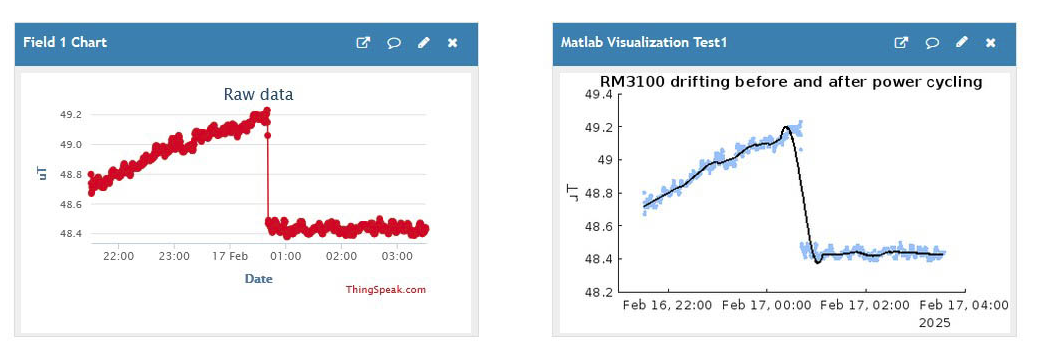

Here is an example of increase noise level; it decreased after power cycling (sensor 'Board 2'):

Another case when sensor reading were drifting linearly immediately after power on; when power was turned off and then re-connected the drifting stopped (sensor 'Board 1'):

Another case when sensor reading were drifting linearly immediately after power on; when power was turned off and then re-connected the drifting stopped (sensor 'Board 1'):

I am not completely sure, but sometimes it looks like first 20-30 minutes after powering the readings are gradually changing in one direction and stabilize after that interval:

As of now I don't have any explanation for such instability; I can suggest this is individual features of my sensor boards; maybe selecting/testing multiple sensor boards could reveal more stable items.

Long Term Measurements

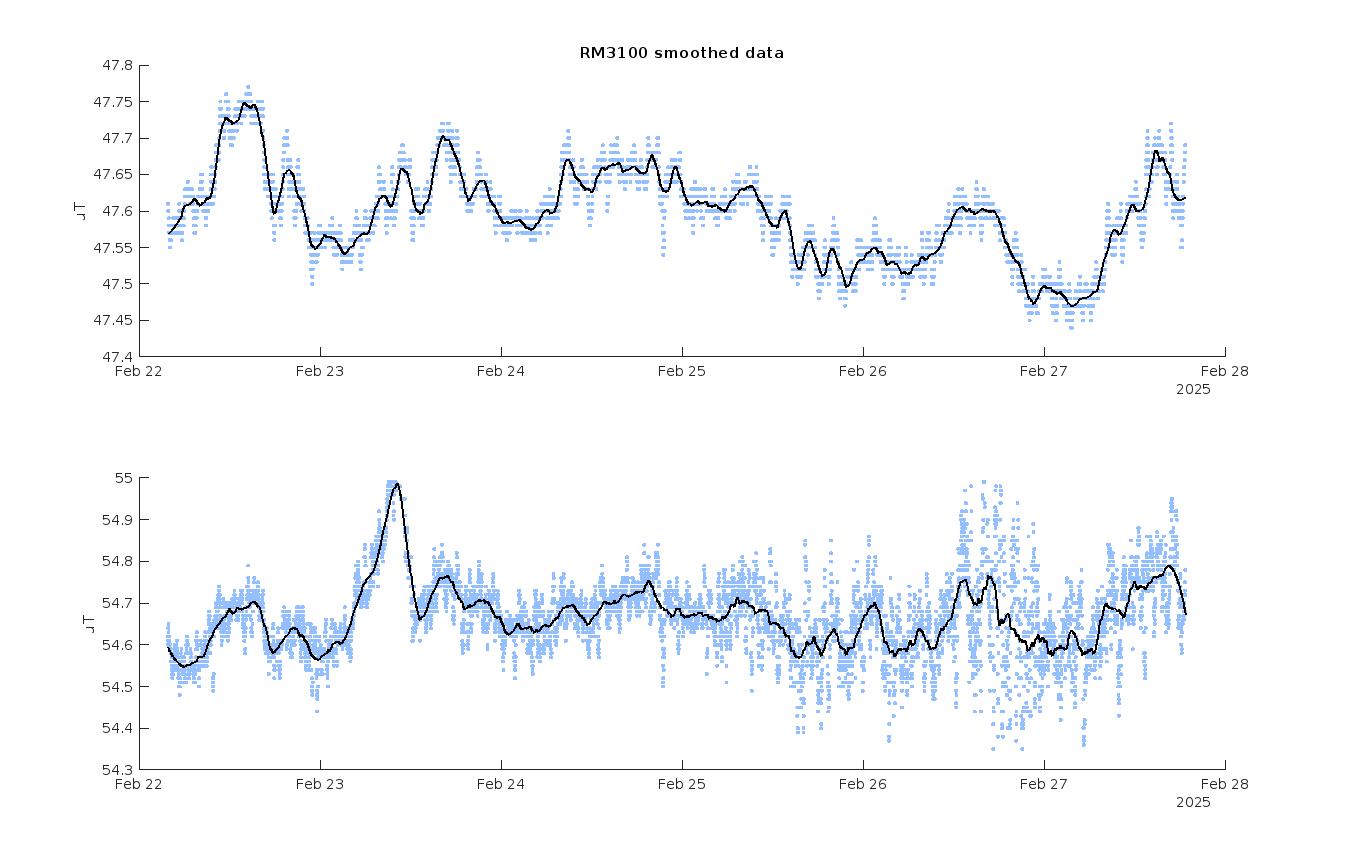

To obtain long-term magnetometer readings I used both sensors simultaneously, both at the same location, each connected to it's own MCU, both MCU were running the identical code, just sending data to different ThingSpeak channels. For these experiments I increased the moving average window size up to 50 readings, readings are acquired 4 times a minute and current average is sent to IoT once a minute. I also modified Matlab program to show plots from both sensors in the same window, for comparison. The idea was to observe a real difference in sensor boards sensitivity and detect simultaneous reading changes, distinguishing them from individual boards outliers and noise.

The result can is available at my public channel https://thingspeak.mathworks.com/channels/2799462

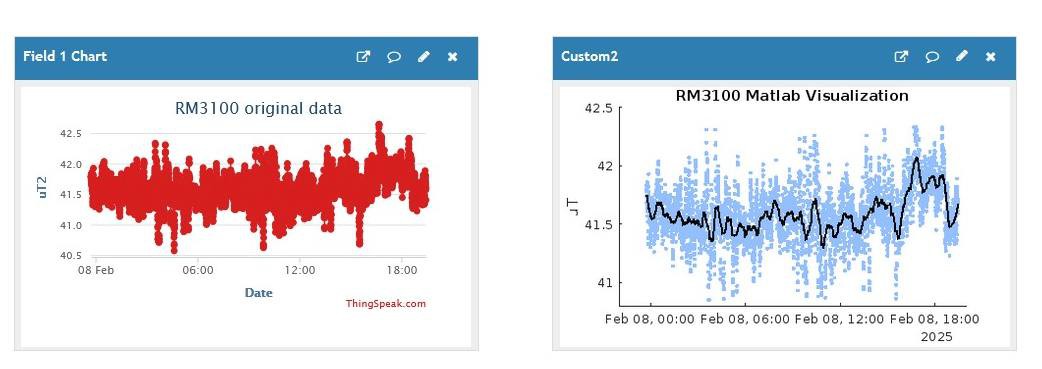

The top chart shows data from sensor 'Board 1' and the bottom one - from 'Board 2'.

Data plot of free account on ThingSpeak can hold up to 8000 data points; so I am planning to run both sensors for a while and these plots theoretically would show 5 days of observations.

Later:

after running both boards in parallel I obtained quite obvious demontration of a difference in boards noise level and sensitivity, with 'Board 1' (top plot) showing way better results:

So I decided to exclude the other board from further data streaming.

Interesting that long-term data plot shows a distinctive daily periodic fluctuations:

I have no idea how this could be interpreted; most probably it somehow reflects daily changes in surrounding electrical devices activity; my magnetometer located on the 5th floor of a huge apartment building near O'Hare airport.

Conclusion

From my observations, RM3100 sensor boards without special shielding have a noise level of 50-200 nT; individual sensor boards have different noise level, different readings when placed in identical conditions; sensors also can demonstrate some instability, like, spontaneous change of noise level and drifting of readings. Power cycling also affects sensors instability.

As I understand, RM3100 sensors initially were not designed for measuring subtle field changes of geomagnetic events; with certain precautions and having in mind possible data instability these boards probably could be used for 'Space weather' observations, especially in case of events of a high intensity, but, by my opinion, mostly for demonstration and hardly for exact measurements.

Konstantin D.

Konstantin D.