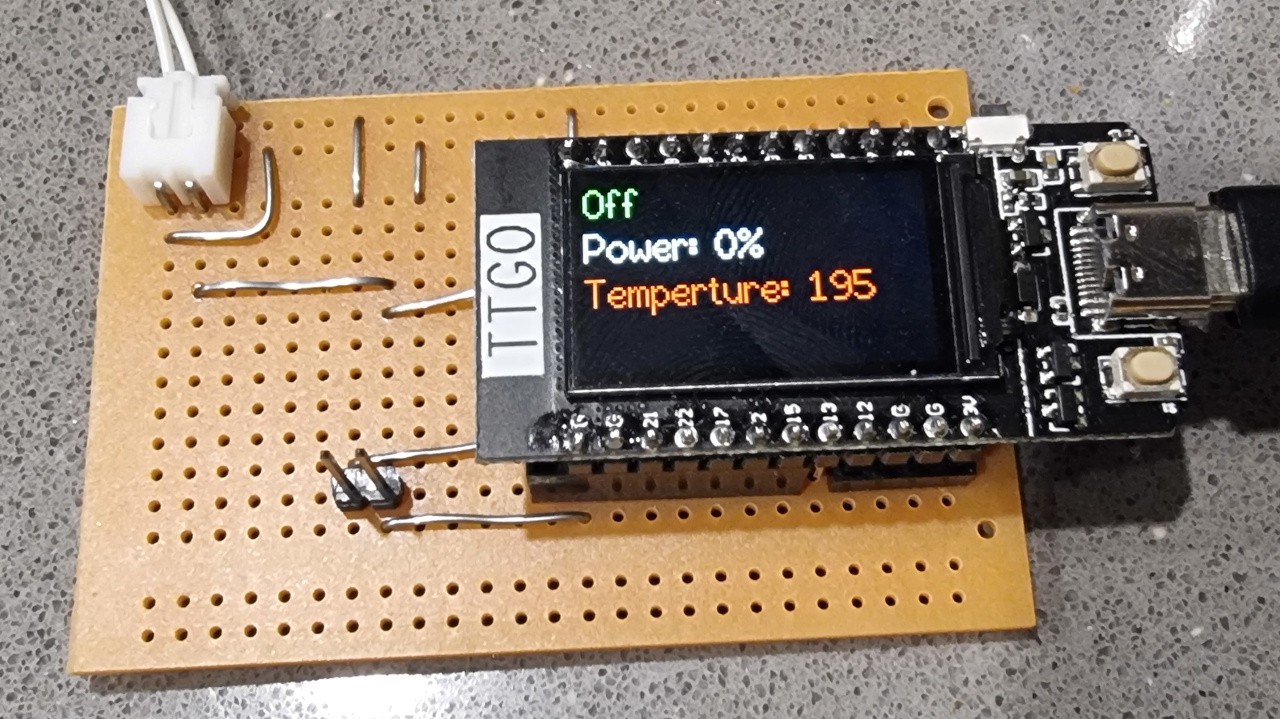

After sending my board off to OSHPark to be created, I decided to build a small prototype board:

Which is when I discovered the fatal flaw in my board design. Primarily i'll be controlling this thing over wifi and I dont really need the display beyond telling me what the temperature in the oven actually is, whether its on and how much power im sending it (maybe some more data later) and even that is optional. Originally I was aiming at the ESP32-S module because I have quite a few, and the lilygo t-display is based on the same chip, but It has one problem I was not aware of, it has 2 ADC's, the second ADC Isn't usable when WiFi is enabled (works fine with ESP32-S2 and later modules, but not the -S). In my "real" board, I have 3 thermistors all tied to ADC2. In reality I can put in a bodge wire, but its a small cheap board so i'll design a new one. I mean its only 3 thermisters and a few GPIO outputs, so its not exactly rocket surgery.

On another note I was originally using the same circuitry for my board that you might find on the majority of 3d Printer boards for the thermistor's (4.7k resister + 10uf cap), which would be good enough in reality, but probably isn't quite accurate enough at the high end. I was willing to live with that because adapting the Marlin PID/temperature routines in the source might have been easy enough (my original plan was to actually adapt the 3d Printer ESP code stream of marlin and modify it to my liking). However, It's been a while since i've looked at the marlin code base and now its a lot harder to isolate that particular section of the code away from the rest. Plus, lets face it, I'm doing this project not cause I really need a reflow oven but because it looked fun to build something from scratch and green-fields.

Ultimately, that's going to change my plans and i'll implement my own PID controller code (after all there are some subtle but very important differences between how you control the temp on a hotend and inside an oven). I'll also probably change the resister out for something in the 1k to 2k range (or perhaps even have each thermistor with slightly different range capabilities (1k/2k/3k perhaps).

I still want to stick with the 3d printer NTC 100k's because the goal of this project is CHEAP! There's no real point building something like this if the price of building it gets close to the cost of the cheap reflow ovens on AliExpress.

... so back to the KiCad Drawing Board

Paul J R

Paul J R

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.