Ok so the first challenge was to see if I can actually make a 3D print waterproof. if not this project is sunk in the water.

For this to work I'm not just talking about whether the print can hold water. But need something that can stand up to some serious water pressure without springing a leak....

if your interested in the phase of the build then be sure to check out the video below as it has all the details of the build so far.

I needed a pressure test rig for that.

Ok so to test whether the sea scooter can to handle this kind of pressure. i first had to design a pressure testing rig!

I went for a design that consists of a polycarbonate cylinder with 3D printed endcaps also out of polycarbonate. well actually polycarbonate carbon fiber in the end... These form a tight seal with the cylinder using a large silicone O-ring. With either end secured in place with 6 pieces of M10 threaded rod. It was then filled with water and a ¼ inch air hose fitting taped into the top so that I could connect it to an air compressor to pressurize the test rig.

The samples where attached to this load spring and submerged in the tank to measure how buoyant they where, and how this changes over time. The idea being that either water iwould ingress and compress the air in the cavity – reducing the buoyancy, or water would ingress and air would leave as a stream of bubbles – reducing the buoyancy. As a back up I also weighted the samples before and after to measure if they took on water.

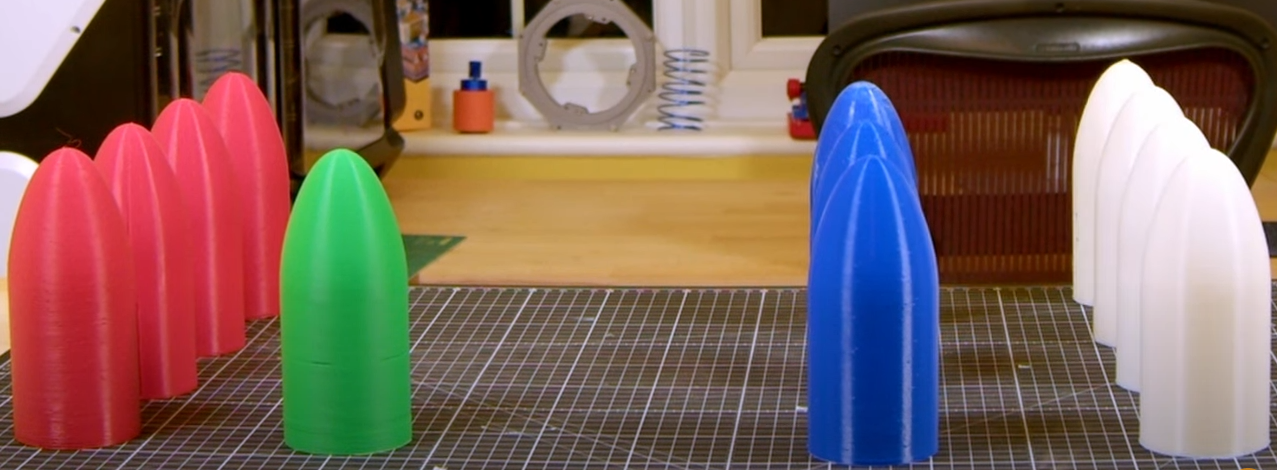

I tested a scaled down, simplified version of a sea scooter hull to make the testing as representative as possible. (white object above)

If you do a quick search you’d find quite a bit of material on ways to water proof a 3d print. It’s not all entirely consistent. but after a bit of thought I think I found a good set of parameters to test. (details in the above video).

I tried ASA as the main contender and PLA as a reference. Trying these at a few different pressures up to a few Atmospheres (Atm) water pressure and also few post processing techniques like acetone smoothing and epoxy coating. So I needed quite a few test hulls......!

There where some surprising results.

But post processing was definitely the way to go. The Epoxy coating in particular was able to stand up to more pressure than you might expect.

Ben

Ben

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.