With the CAD done, we moved on to manufacturing. We started by laser cutting the wooden components. The design was built around 5 mm plywood for almost everything. We used:

- Three 80 cm × 60 cm sheets (5 mm plywood)

- One 50 cm × 50 cm sheet (3 mm plywood)

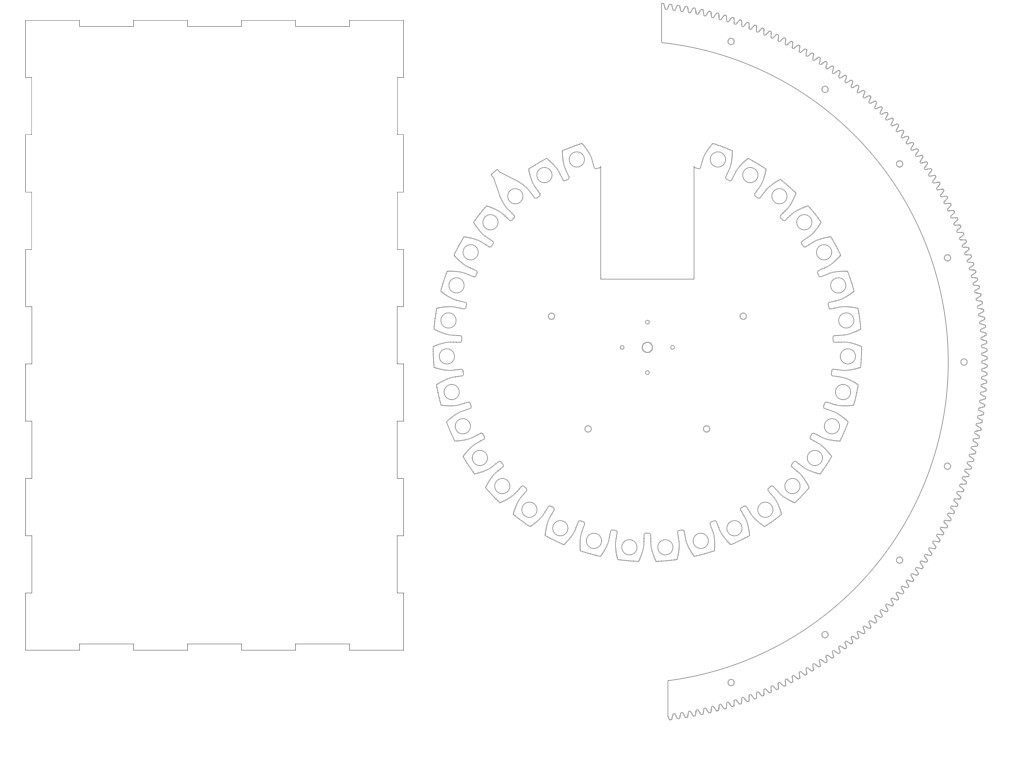

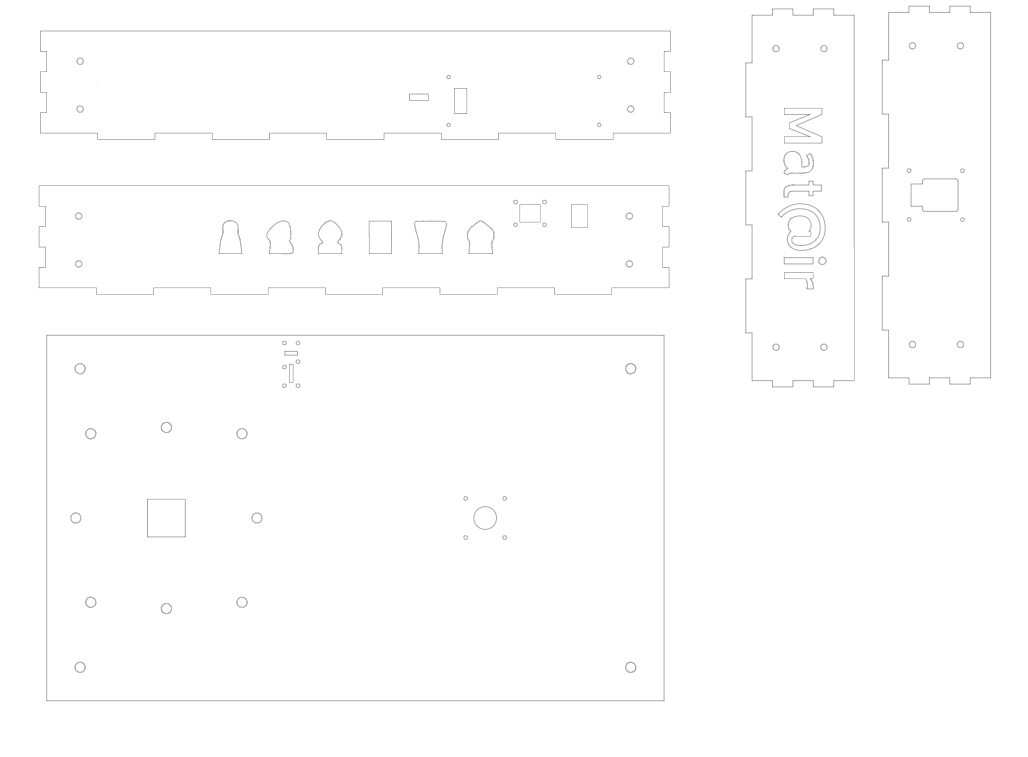

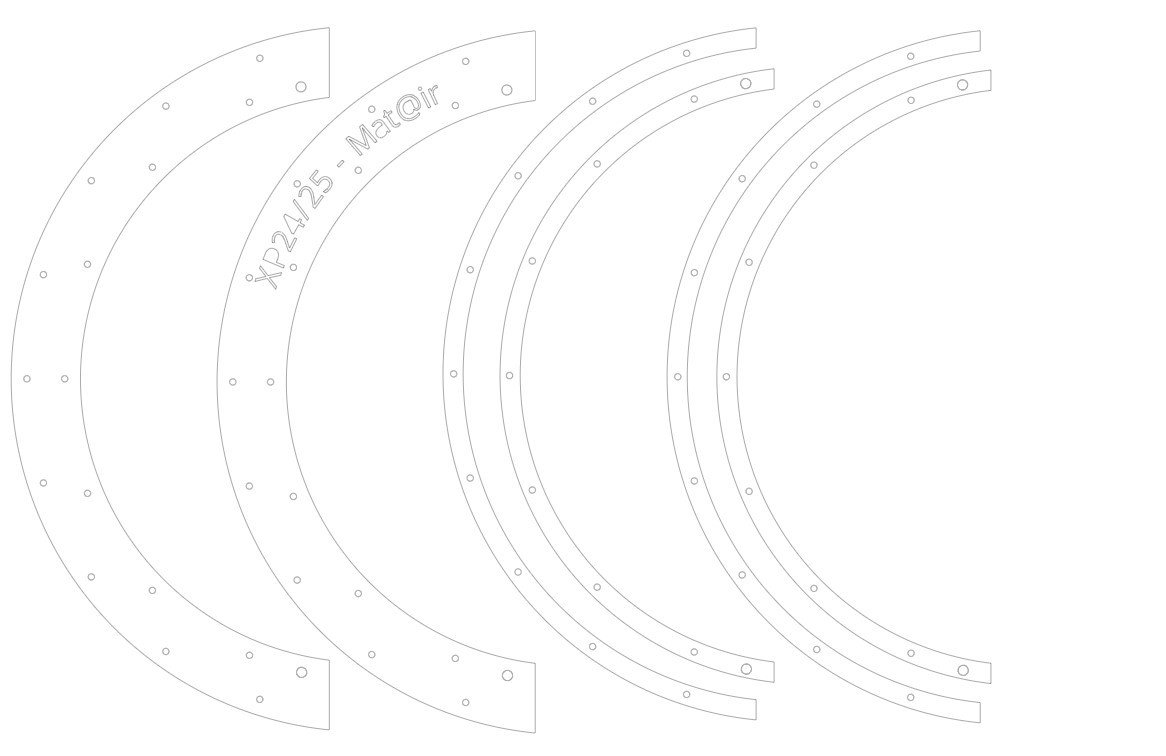

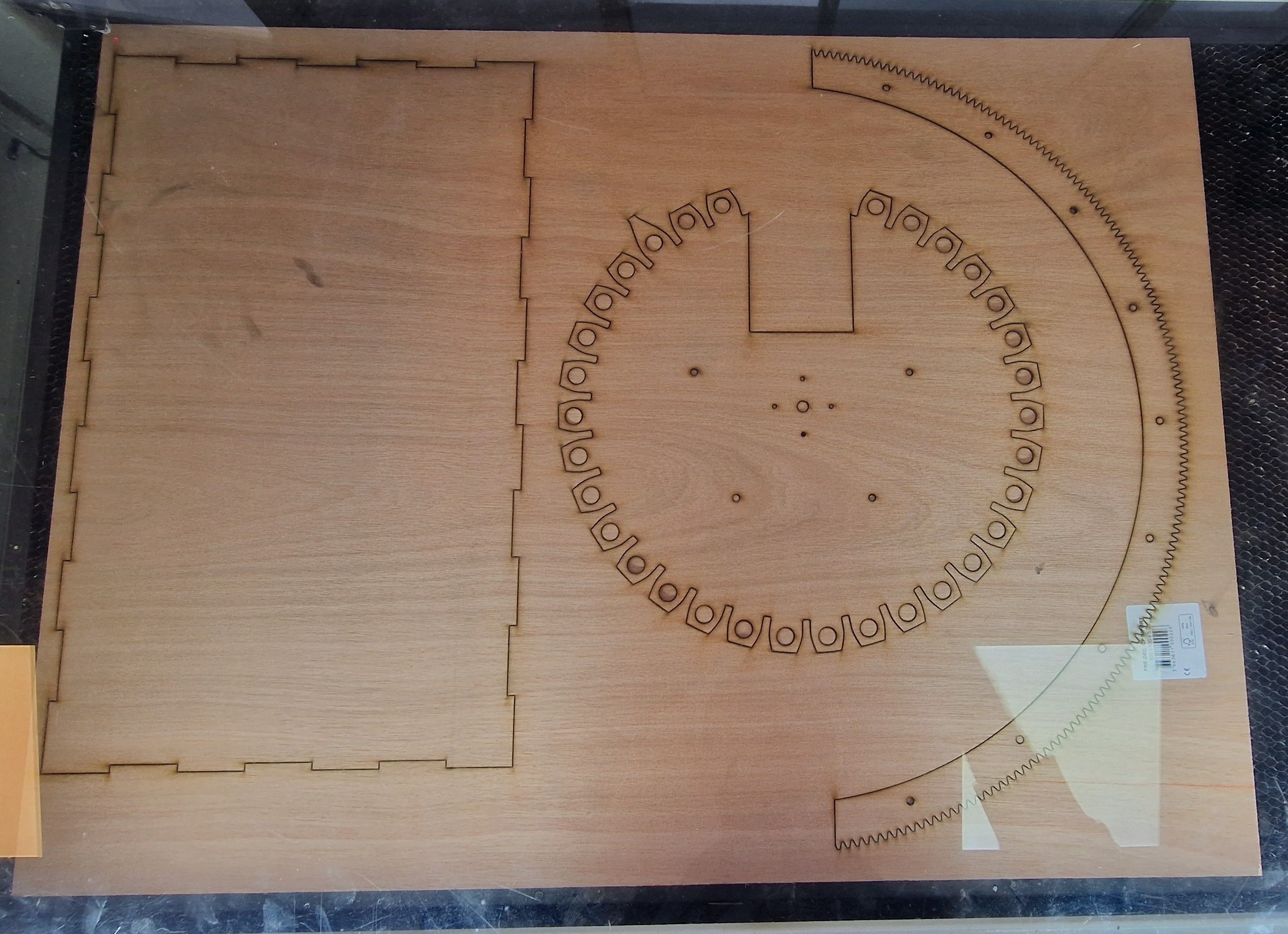

Here is the cutting layout:

5mm plywood | 5mm plywood |

3mm plywood | 5mm plywood |

And here is the cutting process:

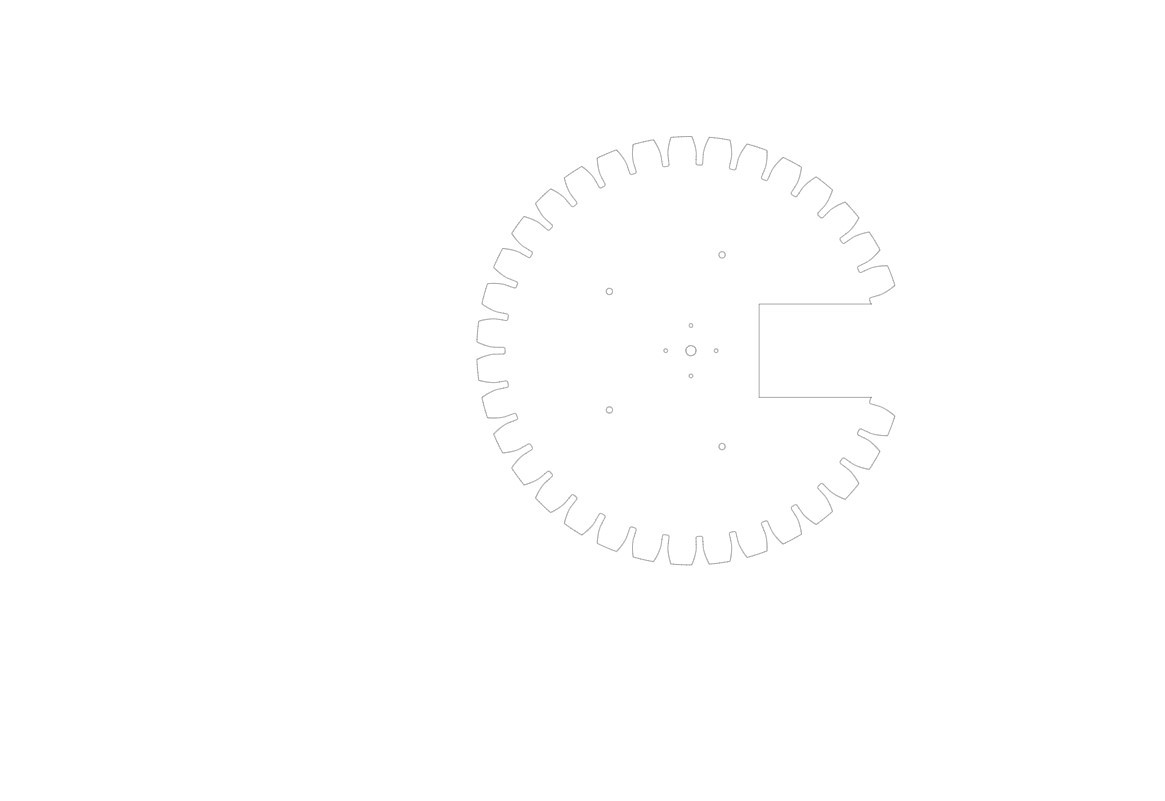

We did run into an issue later with the curved rail plywood gear: the teeth kept snapping off. To fix it, we swapped to 6 mm acrylic instead.

Nasser

Nasser

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.